Polyimide resin composition, polyimide varnish, and polyimide film

A technology of polyimide resin and polyimide film, applied in the direction of coating, etc., can solve problems such as adverse effects of components, achieve high heat resistance and thermal stability, excellent colorless transparency and optical isotropy same-sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0207] Hereinafter, the present invention will be specifically described based on examples. However, the present invention is not limited in any way by these examples.

[0208] The solid content concentration of the polyimide varnish obtained in the Example and the comparative example, and each physical property of a polyimide film were measured by the method shown below.

[0209] (1) Solid content concentration

[0210] The solid content concentration of the polyimide varnish was measured by heating the sample at 320° C.×120 minutes in a small electric furnace “MMF-1” manufactured by AS ONE Corporation, and calculating from the mass difference of the sample before and after heating.

[0211] (2) Film thickness

[0212] The film thickness was measured with a micrometer manufactured by Mitutoyo Co., Ltd.

[0213] (3) Total light transmittance, yellow index (YI)

[0214] The total light transmittance and YI were measured according to JIS K7361-1:1997 using a color / turbidity ...

Synthetic example 1

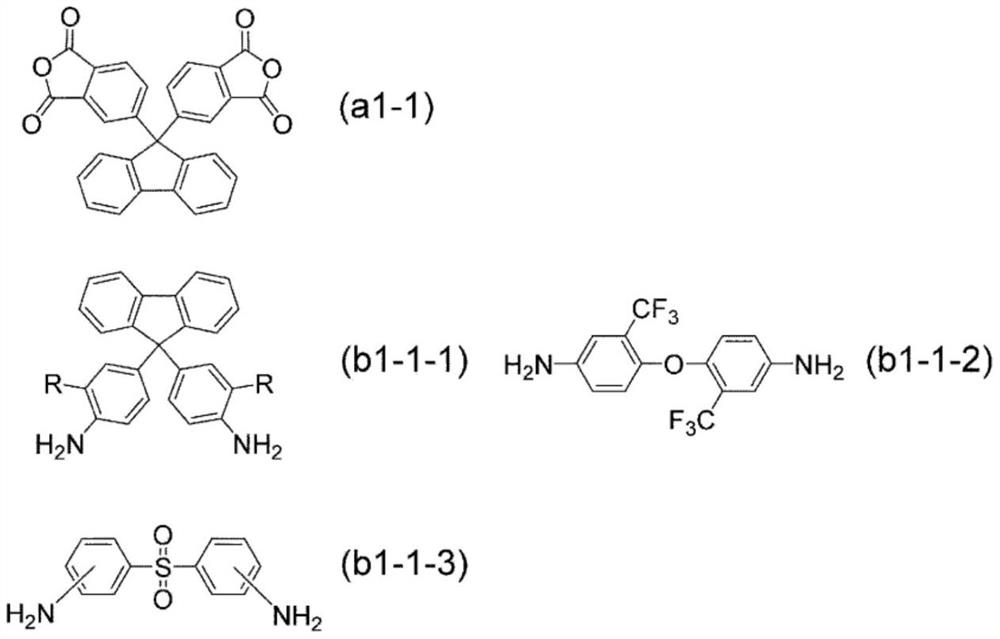

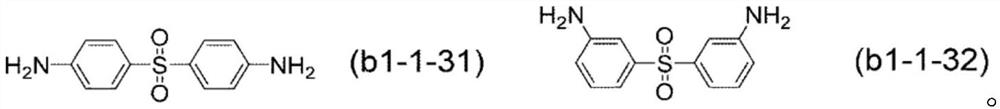

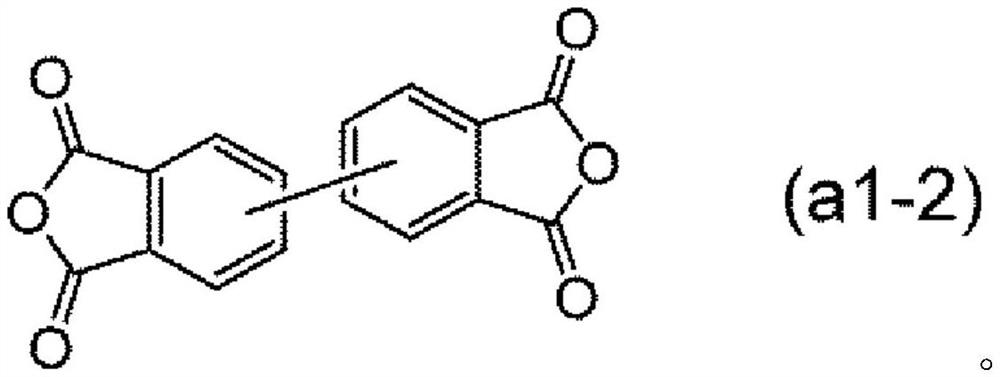

[0244] 34.845 g (0.100 g (0.100 g) were put into a 1 L five-neck round-bottomed flask equipped with a stainless steel half-moon-shaped stirring blade, a nitrogen introduction tube, a condenser tube, a Dean-Stark trap, a thermometer, and a glass end cap. mol) of BAFL and 98.826 g of NMP were stirred at a temperature of 70° C. in the system, under a nitrogen atmosphere, and at a rotational speed of 150 rpm to obtain a solution.

[0245]To this solution, 45.843 g (0.100 mol) of BPAF and 24.206 g of NMP were simultaneously added, and then 0.506 g of TEA as an imidization catalyst was added, heated in a covered heater, and reacted for about 20 minutes. The temperature in the system was raised to 190°C. The components removed by distillation were collected, the rotational speed was adjusted as the viscosity increased, and the temperature in the reaction system was maintained at 190° C. to perform reflux for 3 hours.

[0246] Then, 572.724 g of NMP was added, and after cooling the t...

Synthetic example 2

[0248] A polyimide varnish was prepared in the same manner as in Synthesis Example 1, except that 34.845 g (0.100 mol) of BAFL was changed to 33.620 g (0.100 mol) of 6FODA, and a polyimide varnish having a solid content concentration of 10.0 mass % was obtained. Imide varnish.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com