Method for preparing battery lithium carbonate by continuously carbonizing industrial-grade lithium carbonate

A lithium carbonate, industrial-grade technology, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve problems such as continuous production, improve production efficiency, improve conversion rate and the degree of automation of production equipment, improve safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

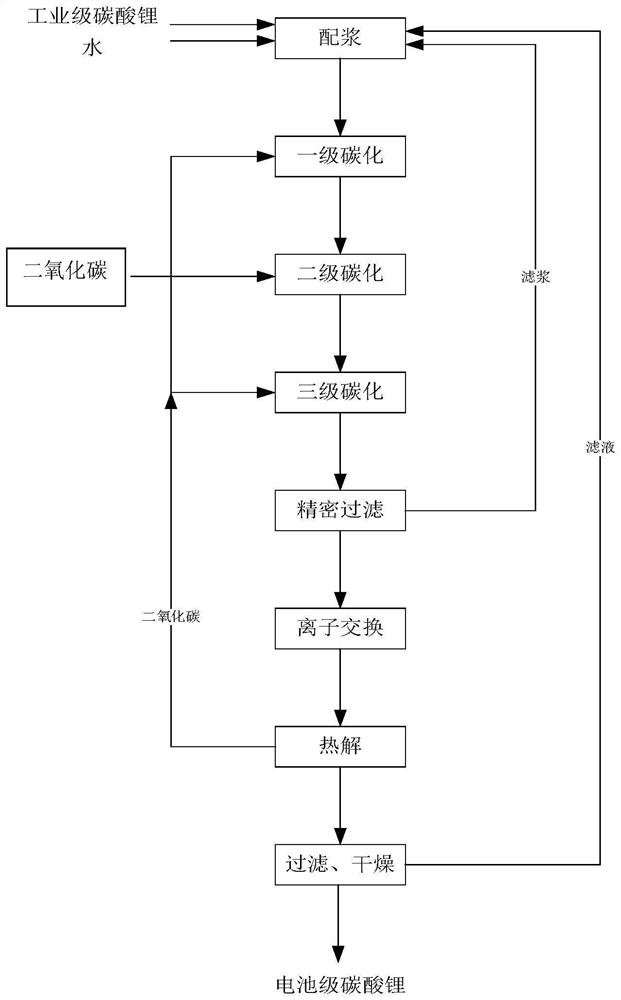

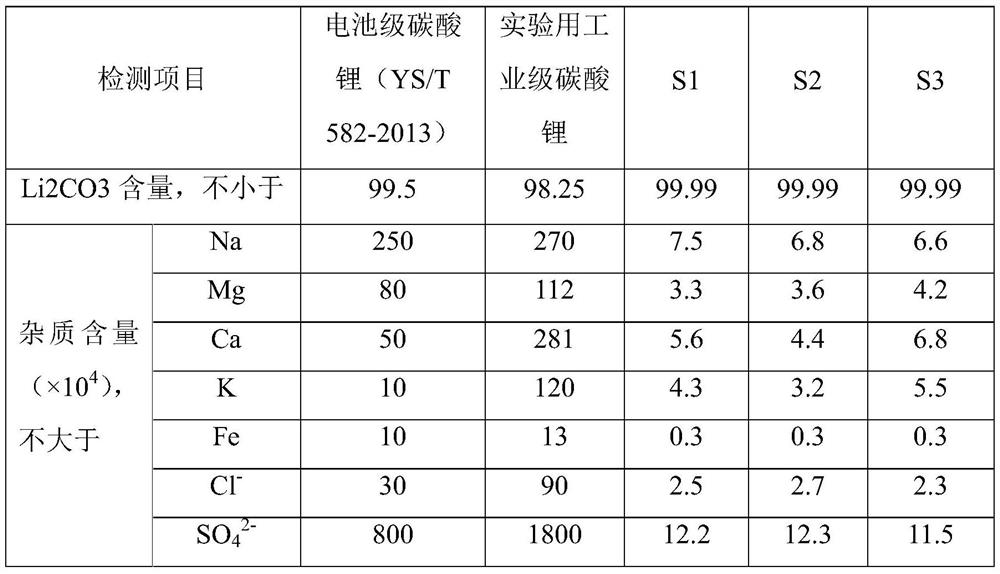

[0020] A method for preparing battery lithium carbonate by continuous carbonization of industrial grade lithium carbonate comprises the following steps:

[0021] 1. Make a slurry of lithium carbonate and battery water according to a solid-to-liquid ratio of 1:24, start stirring and stir well; transport the lithium carbonate slurry to the carbonization kettle through a metering pump, and feed carbon dioxide into the three carbonization kettles at the same time The carbonization reaction of the gas is carried out, and the flow rate is adjusted to 35L / min. During the reaction, the pressure in the reactor is controlled by adjusting the exhaust valve within the range of 40Kpa to 60Kpa, and the residence time of the carbonization reaction is controlled for 1h until the material in the reactor is clarified; Carbon dioxide is continuously introduced, and the feed flow rate is controlled at 2.5L / min. Lithium carbonate slurry is continuously added to the first-stage carbonization kettle,...

Embodiment 2

[0025] A method for preparing battery lithium carbonate by continuous carbonization of industrial grade lithium carbonate comprises the following steps:

[0026] 1. Make a slurry of lithium carbonate and battery water according to the solid-to-liquid ratio of 1:24, start stirring and fully stir; transport the lithium carbonate slurry to the carbonization kettle through a metering pump, and feed carbon dioxide gas into the three carbonization kettles at the same time Carry out the carbonization reaction, adjust the flow rate to 30L / min, control the pressure in the reactor by adjusting the exhaust valve to keep it in the range of 40Kpa~60Kpa during the reaction, control the residence time of the carbonization reaction for 1h, until the material in the kettle is clarified; keep the carbon dioxide in the carbonization kettle Continuous feeding, controlling the feed flow rate to 2.5L / min and continuously adding lithium carbonate slurry to the first-stage carbonization kettle, the re...

Embodiment 3

[0030] A method for preparing battery lithium carbonate by continuous carbonization of industrial grade lithium carbonate comprises the following steps:

[0031] 1. Make a slurry of lithium carbonate and battery water according to the solid-to-liquid ratio of 1:27, start stirring and fully stir evenly; transport the lithium carbonate slurry to the carbonization kettle through a metering pump, and feed carbon dioxide into the three carbonization kettles at the same time The carbonization reaction of the gas is carried out, and the flow rate is adjusted to 35L / min. During the reaction, the pressure in the reactor is controlled by adjusting the exhaust valve to keep it within the range of 40Kpa~60Kpa, and the carbonization reaction time is controlled for 1h until the material in the kettle is clarified; keep the carbon dioxide in the carbonization kettle Continuous feeding, controlling the feed flow rate to 2.7L / min and continuously adding lithium carbonate slurry to the first-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com