Jet dry material with low rebound rate and preparation method thereof

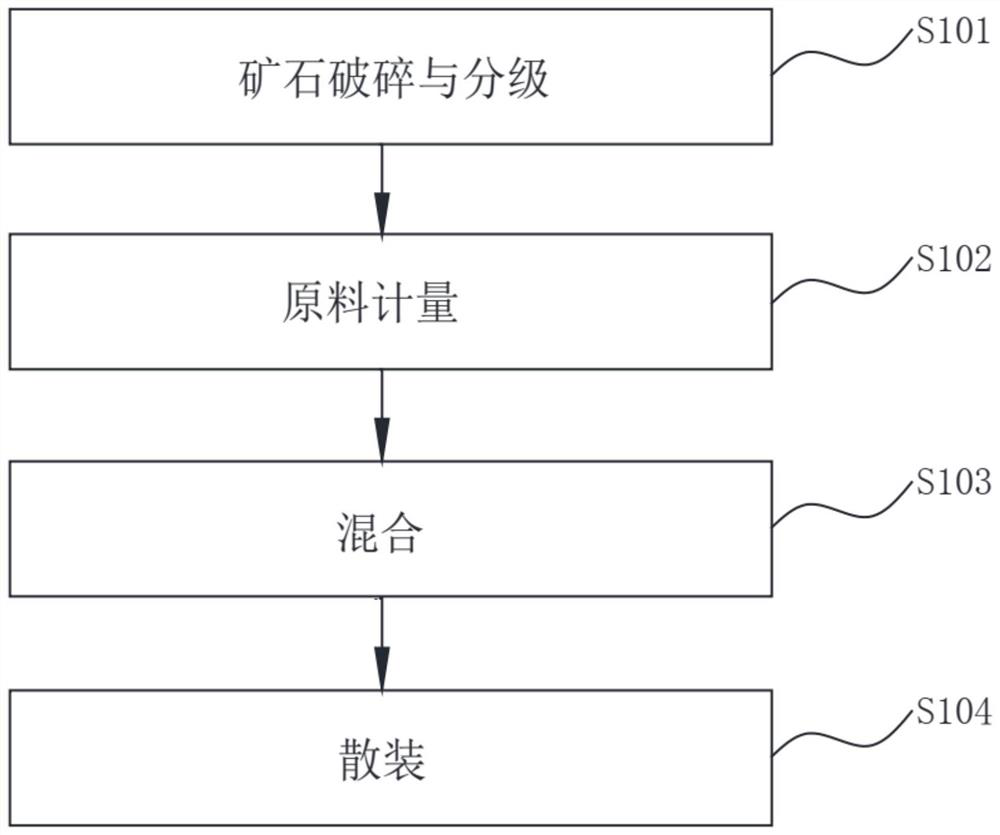

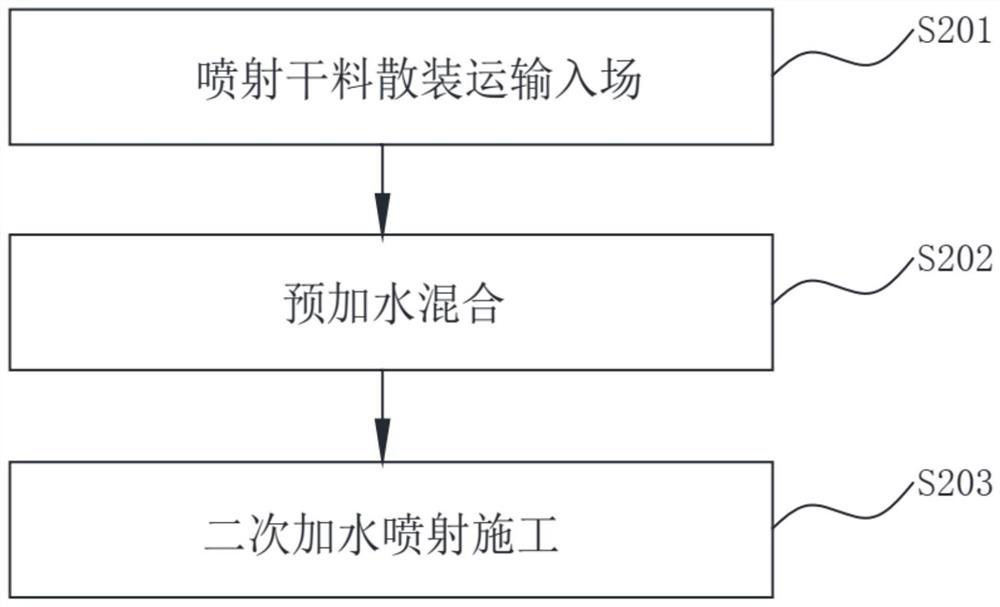

A low-rebound, dry-material technology, used in the preparation of test samples, excavation, and earth-moving drilling, etc., can solve the problems of large fluctuations in the strength of shotcrete, the inability to add accelerators in advance, and the easy blockage of pumps and pipes. , to achieve the effect of convenient and efficient construction process, good construction effect and promotion significance, and the effect of reducing rebound rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0030] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

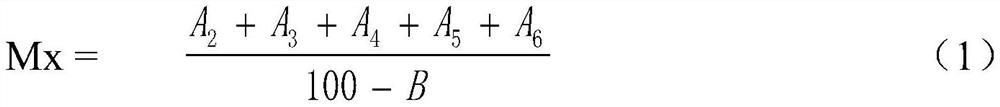

[0031] According to a preferred embodiment of the present invention, it is a low-rebound spray dry material, a low-rebound spray dry material, and the components of the spray dry material include: ordinary cement 200, special cement 20, Admixture 30, graded aggregate 733.85, cellulose ether 0.15, fiber 1, antifreeze agent 15, ordinary cement is type II 42.5 Portland cement, special cement is 42.5 rapid hardening sulfoalumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com