Isocyanate grafted natural unsaturated phenol white carbon black dispersing agent as well as preparation method and application thereof

A technology of isocyanate and phenolic silica, applied in the field of rubber processing aids, can solve the problems of poor compatibility and little help in the physical and mechanical properties of rubber materials, and achieve the effects of wide application, good reactivity, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

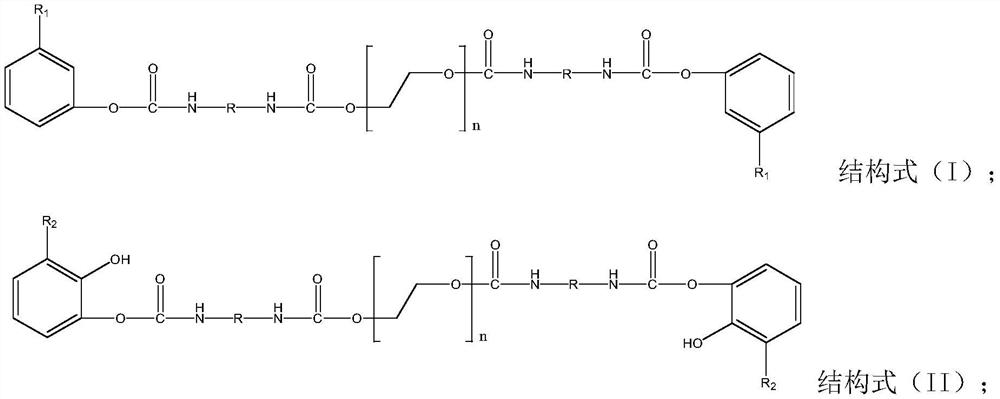

[0034] Add 30.0g cardanol and 37.5g MDI to a 500ml round bottom flask equipped with stirring, temperature control, reflux condenser and dropping funnel, under nitrogen protection, react at 95°C for 3.5h, absorb the tail gas with distilled water, the sample is light yellow and viscous liquid; after cooling down to 60°C, slowly add 30.0g of polyethylene glycol-600 dropwise through a constant pressure funnel, and maintain the reaction at 60°C for 1.5h to obtain the isocyanate-grafted natural unsaturated phenolic silica dispersant; heat The isocyanate grafted natural unsaturated phenolic silica dispersant is poured out and cooled to obtain the isocyanate grafted natural unsaturated phenolic silica dispersant solid.

Embodiment 2

[0036] Add 30.0g cardanol and 37.5g MDI to a 500ml round bottom flask equipped with stirring, temperature control, reflux condenser and dropping funnel, under nitrogen protection, react at 85°C for 2.5h, absorb the tail gas with distilled water, the sample is light yellow and viscous liquid; after cooling down to 70°C, slowly add 75.0g of polyethylene glycol-1500 dropwise through a constant pressure funnel, and maintain the reaction at 70°C for 2 hours to obtain the isocyanate-grafted natural unsaturated phenolic silica dispersant; put the hot The isocyanate grafted natural unsaturated phenolic silica dispersant is poured out and cooled to obtain the isocyanate grafted natural unsaturated phenolic silica dispersant solid.

Embodiment 3

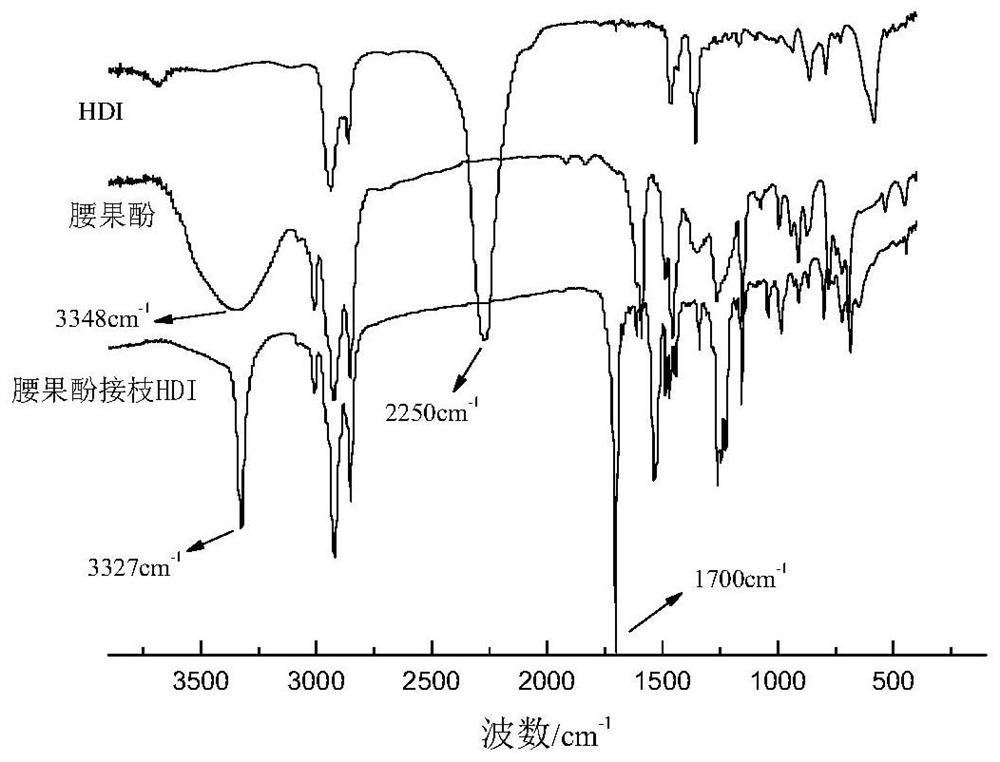

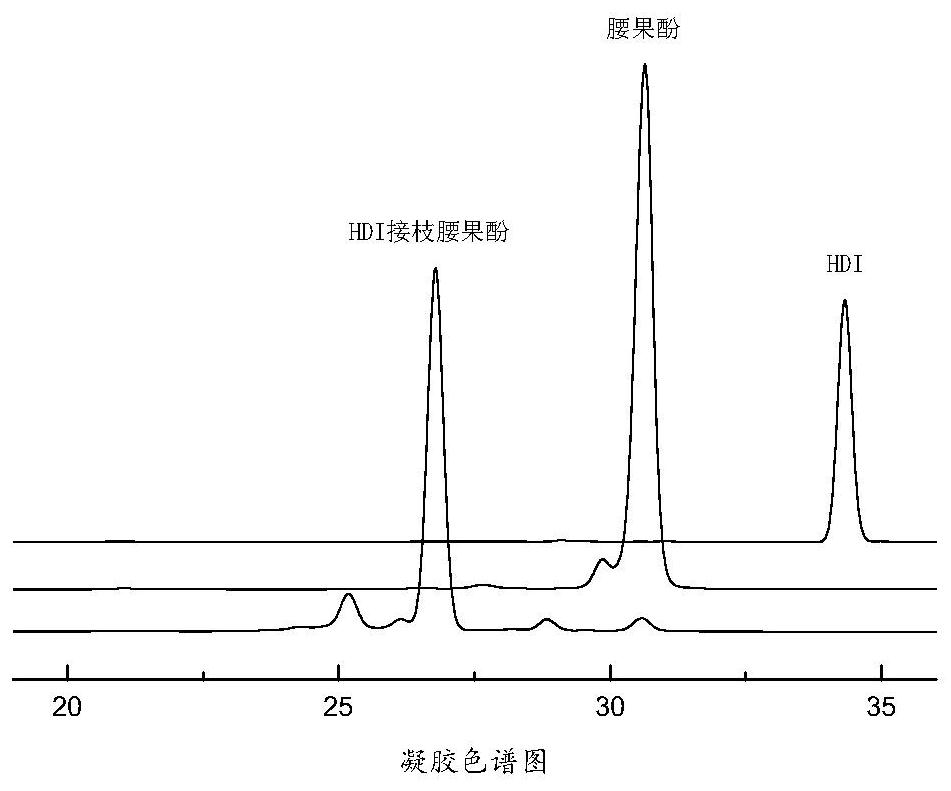

[0038]Add 30.0g of cardanol and 25.2g of HDI to a 500ml round bottom flask equipped with stirring, temperature control, reflux condenser and dropping funnel, under nitrogen protection, react at 80°C for 2h, absorb the tail gas with distilled water, the sample is light yellow viscous liquid After cooling down to 65°C, slowly add 30.0g of polyethylene glycol-600 dropwise through a constant pressure funnel, and keep it at 65°C for 1 hour to obtain the isocyanate-grafted natural unsaturated phenolic silica dispersant; the hot isocyanate The grafted natural unsaturated phenolic silica dispersant is poured out and cooled to obtain the solid of isocyanate grafted natural unsaturated phenolic silica dispersant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com