Polyamide film, cover window comprising same, and display device

A polyamide film and polyamide technology, applied in the field of cover windows and display devices, can solve problems such as damage to optical properties, achieve excellent optical properties and mechanical properties, maintain optical properties and mechanical properties, and increase wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

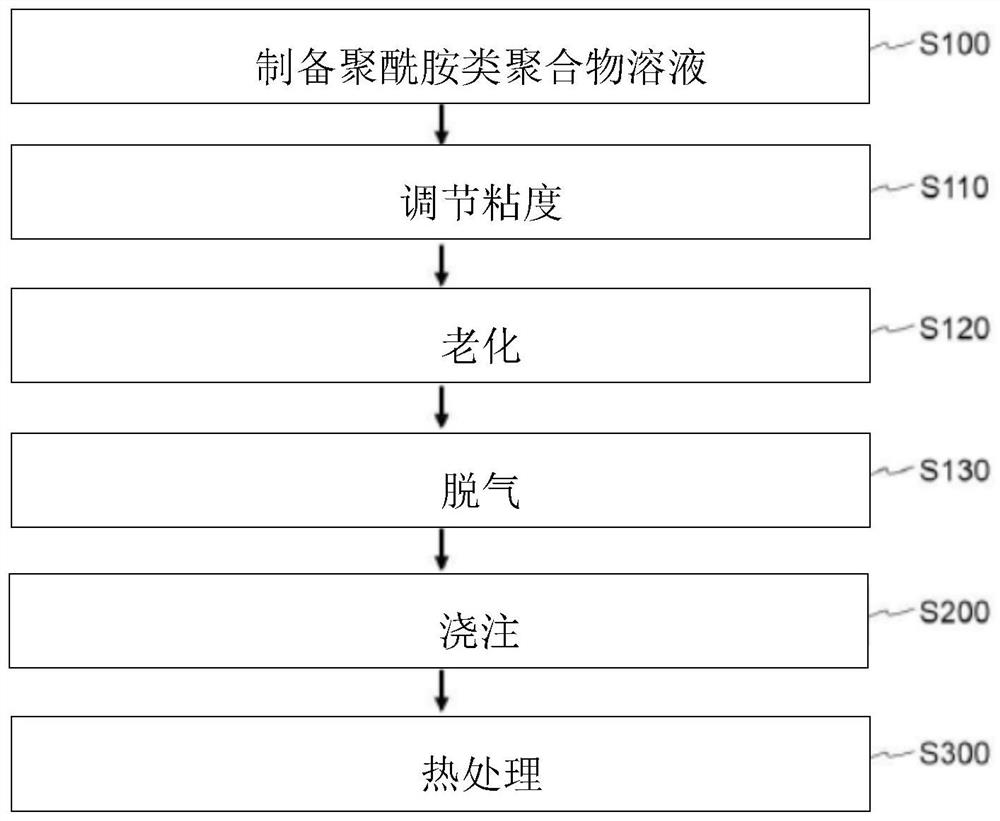

[0288] At 10° C. under a nitrogen atmosphere, 567 g of dimethylacetamide (DMAc) was charged as an organic solvent into a 1 liter glass reactor equipped with a temperature-controllable double jacket. Then, 64.0 g (0.200 mol) of 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl (TFDB) as an aromatic diamine was slowly added thereto and dissolved.

[0289] Subsequently, terephthaloyl chloride (TPC) as the first dicarbonyl compound was slowly added, and then the mixture was stirred for 1 hour. Then, isophthaloyl chloride (IPC) as a second dicarbonyl compound was added in an amount of 94% based on the total introduced amount, followed by stirring the mixture for 1 hour, thereby preparing a first polymer solution.

[0290] A 10% by weight solution of IPC in DMAc organic solvent was prepared.

[0291] 1 ml of the IPC solution was added to the first polymer solution, and the mixture was stirred for 30 minutes, and the process was repeated. About 6% of IPC based on the total amount intr...

Embodiment 2-5 and comparative example 1-3

[0295] A film was prepared in the same manner as in Example 1 except that, as shown in Table 1 below, the content of each reactant, polymerization temperature, and drying temperature were changed. In Example 3, 2,2'-bis(3,4-dicarboxyphenyl)hexafluoropropane dianhydride (6-FDA) was further used during polymerization of the polyamide polymer.

[0296] 【Evaluation example】

[0297] The following properties of the films prepared in Examples and Comparative Examples were measured and evaluated, respectively. The results are shown in Table 1 and Table 2 below.

[0298] Evaluation Example 1: Surface Energy Analysis

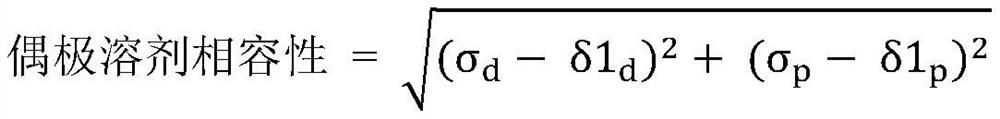

[0299] The surfaces of the polyamide films of Examples and Comparative Examples were cleaned. Then, KRUSS's MSA (Mobile Surface Analyzer) was placed on the surface, and the surface free energy, nonpolar (dispersive part) and polarity (polar part) calculated by the OWRK method were measured. In the measurement, water was selected as the polar solvent, and diiodomethan...

example 3

[0304] Evaluation Example 3: Measurement of Film Thickness

[0305] The thickness was measured at 10 points on the film using a digital micrometer 547-401 manufactured by Mitutoyo Corporation. Get their average.

[0306] Evaluation Example 4: Measurement of Modulus

[0307] The samples were cut at least 10 cm perpendicular to the main shrinking direction of the film and 10 cm in the main shrinking direction. In Instron's universal testing machine UTM 5566A, it is fixed by clamps arranged at intervals of 10 cm. Stretch the sample at room temperature at a rate of 12.5 mm / min until the sample breaks, and obtain a stress-strain curve. The slope of the load with respect to the initial strain on the stress-strain curve was taken as the modulus (GPa).

[0308] Evaluation Example 5: Measurement of light transmittance and haze

[0309] Light transmittance and haze were measured using a haze meter NDH-5000W manufactured by Nippon Denshoku Kogyo according to JIS K 7136 standar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com