Heat-shrinkable material, heat-shrinkable sleeve and preparation method

A heat-shrinkable sleeve and heat-shrinkable technology, applied in the field of materials, can solve the problems of high shrinkage ratio of heat-shrinkable materials, wide range of heat-shrinkable temperature, and difficult-to-tear heat-shrinkable materials, achieving strong tightening force and easy tearing Ability, color transparent, easy to remove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

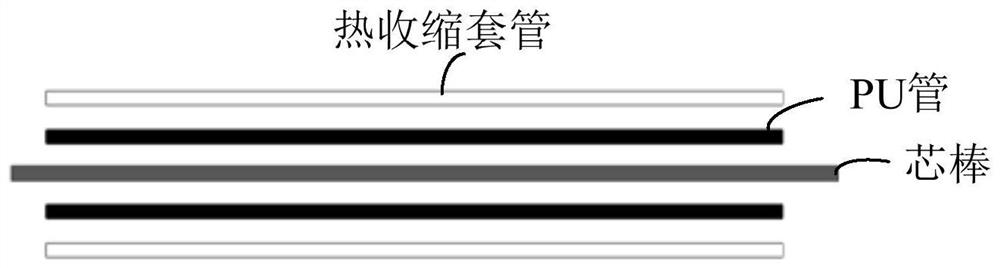

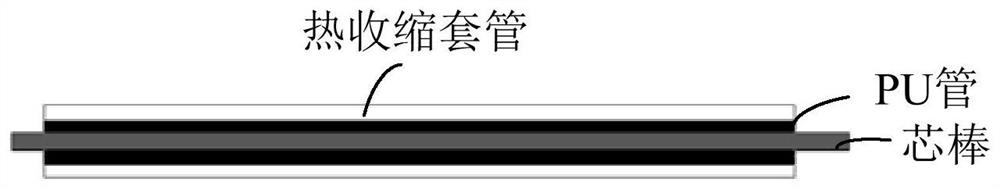

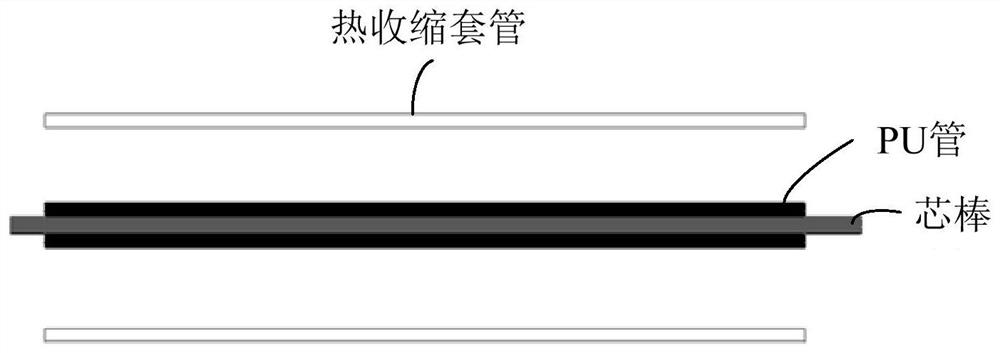

Image

Examples

preparation example Construction

[0052] The present invention also proposes a method for preparing a heat-shrinkable sleeve, which is used to prepare the above-mentioned heat-shrinkable sleeve, comprising the following steps:

[0053] Masterbatch processing: Stir and mix low-density polyethylene, linear low-density polyethylene, ethylene copolymer, antioxidant and nucleating agent evenly, then add finely ground polyethylene wax, stir evenly, extrude and cool to obtain kneading Materials; wherein, the extrusion temperature is 130°C-180°C;

[0054] Extruding into a tube: extruding the mixed material to obtain a semi-finished casing; wherein, the extrusion temperature of the mixed material is 130°C-190°C;

[0055] Irradiation: irradiating the semi-finished casing through an electron accelerator or a cobalt source;

[0056] Expansion and cooling: after irradiation, the semi-finished sleeve is expanded at 130-260° C.; then cooled and shaped to obtain a heat-shrinkable sleeve; wherein, the expansion ratio is 2-4. ...

Embodiment 1

[0063] A heat-shrinkable sleeve, in parts by weight, its preparation materials include: 80 parts of low-density polyethylene, 10 parts of linear low-density polyethylene, 10 parts of ethylene-vinyl acetate copolymer (EVA), hindered phenolic antioxidant 0.05 parts, 2 parts of polyethylene wax, 0.3 parts of sorbitol.

[0064] The preparation method of the heat-shrinkable sleeve:

[0065] Masterbatch processing: Stir and mix low-density polyethylene, linear low-density polyethylene, EVA, hindered phenolic antioxidants and sorbitol evenly, then add finely ground polyethylene wax, stir evenly, extrude and cool to obtain kneading Materials; wherein, the extrusion temperature is 130°C-180°C;

[0066] Extruding into a tube: extruding the mixed material to obtain a semi-finished casing; wherein, the extrusion temperature of the mixed material is 130°C-190°C;

[0067] Irradiation: irradiating the semi-finished casing through an electron accelerator or a cobalt source;

[0068] Expans...

Embodiment 2

[0070] A heat-shrinkable sleeve, in parts by weight, its preparation materials include: 70 parts of low-density polyethylene, 10 parts of linear low-density polyethylene, 20 parts of EVA, 0.3 parts of hindered phenolic antioxidant, 1 part of polyethylene wax, 0.2 parts of sorbitol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com