Optical temperature sensing material and application thereof

A sensing material, optical technology, applied in the field of optical temperature sensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of optical temperature sensing material SrZn of the present invention 0.33 Nb 0.67 o 3 :Pr 3+ (SZNO 1.25%Pr 3+ ), its preparation method comprises the following steps:

[0029] Raw material: SrCO 3 3mmol, Nb 2 o 5 1mmol, ZnO 1mmol, Pr 6 o 11 0.00625mmol, absolute ethanol 5mL.

[0030] 3mmol SrCO 3 , 1 mmol Nb 2 o 5 , 1mmol ZnO, 0.00625mmol Pr 6 o 11 , 5mL of absolute ethanol was mixed and ground in an agate mortar for 30min, the obtained powder was put into a corundum crucible and placed in a muffle furnace for calcination at 800°C for 2 hours, then poured into an agate mortar and ground again evenly, Then put it into a corundum crucible and calcinate in a muffle furnace at 1350°C for 8 hours. After taking out the sample, grind it until the particles are uniform.

Embodiment 2

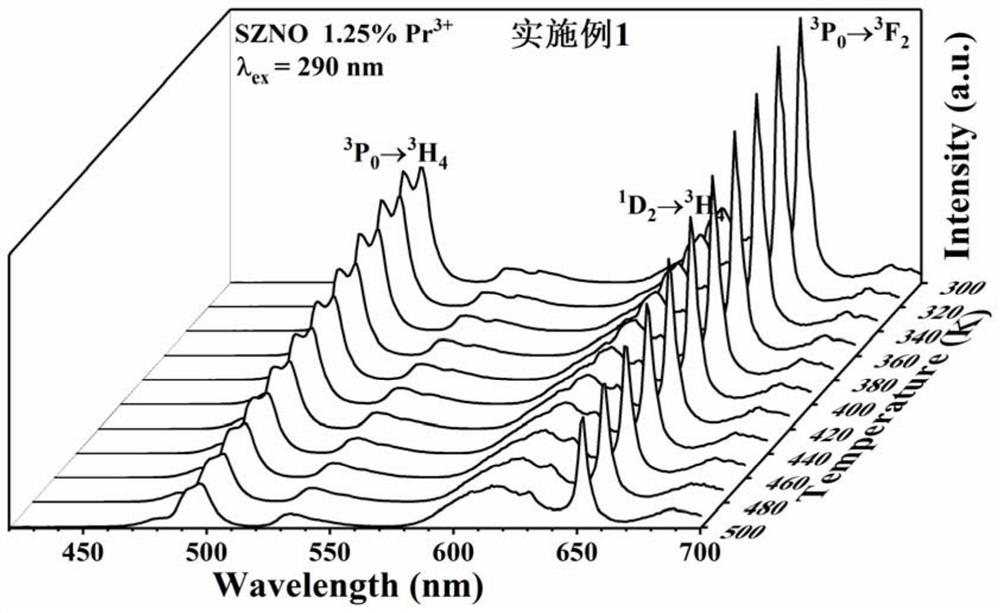

[0032] A kind of optical temperature sensing material SrZn of the present invention 0.33 Nb 0.67 o 3 :Pr 3+ application, the specific method is:

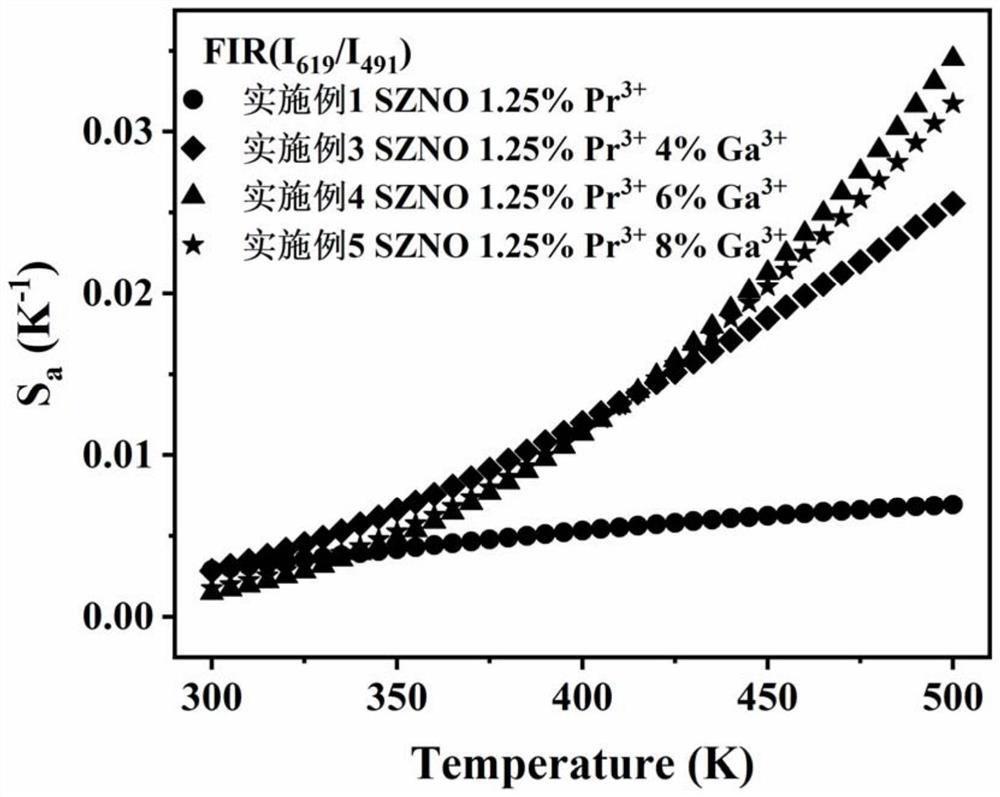

[0033] Excite SrZn with UV light at 290nm 0.33 Nb 0.67 o 3 :Pr 3+ , using FLS980 fluorescence spectrometer for SrZn 0.33 Nb 0.67 o 3 :Pr 3+ The fluorescent powder is tested for variable temperature emission spectrum, and the ratio of the emission peak intensity at 491nm (take the integrated intensity of 483nm to 508nm) to the emission peak intensity at 619nm (take the integrated intensity of 590nm to 640nm) is calculated. 619 / I 491 , and then compared in the function diagram, the required temperature can be obtained.

Embodiment 3

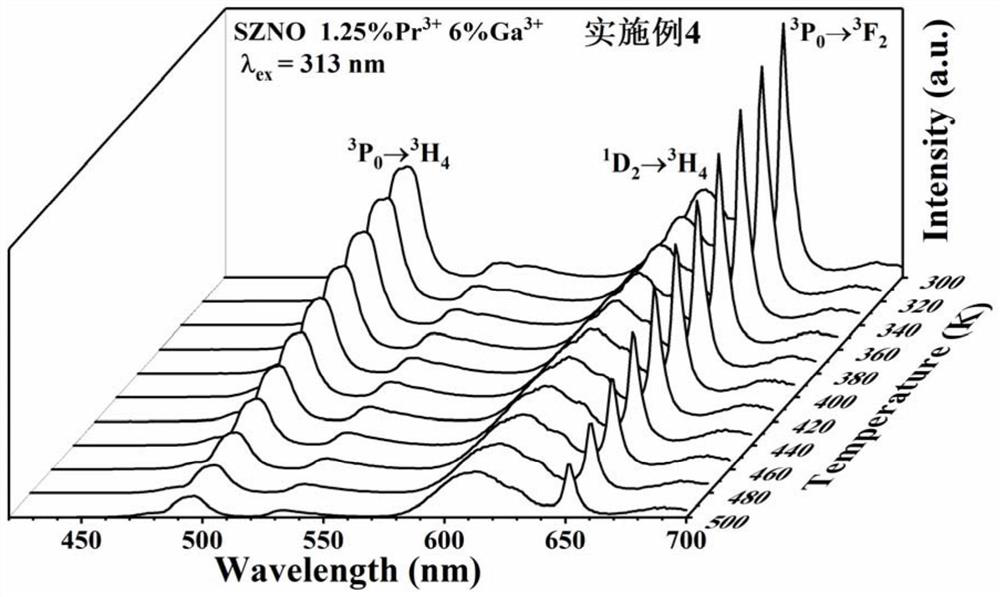

[0035] A kind of optical temperature sensing material SrZn of the present invention 0.33 Nb 0.67 o 3 :Pr 3+ / Ga 3+ (SZNO1.25%Pr 3+ 4%Ga 3+ ), its preparation method comprises the following steps:

[0036] Raw material: SrCO 3 3mmol, Nb 2 o 5 1mmol, ZnO 1mmol, Pr 6 o 11 0.00625mmol, Ga 2 o 3 0.06mmol, absolute ethanol 5mL.

[0037] 3mmol SrCO 3 , 1 mmol Nb 2 o 5 , 1 mmol ZnO, 0.00625 mmol Pr 6 o 11 , 0.06 mmol Ga 2 o 3 , 5mL of absolute ethanol was mixed and ground in an agate mortar for 30min, the obtained powder was put into a corundum crucible and placed in a muffle furnace for calcination at 800°C for 2 hours, then poured into an agate mortar and ground again evenly, Then put it into a corundum crucible and calcinate in a muffle furnace at 1350°C for 8 hours. After taking out the sample, grind it until the particles are uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com