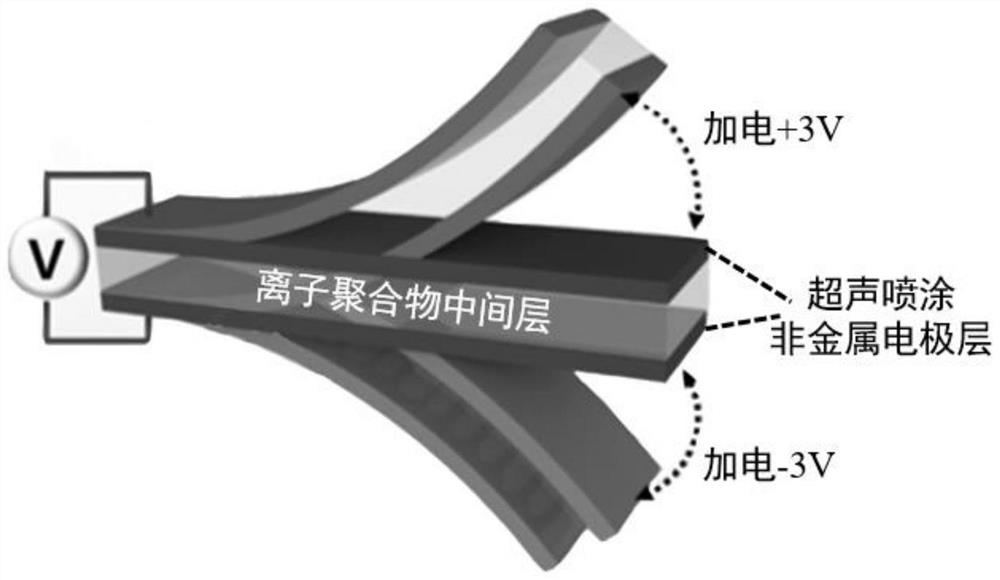

Flexible electric actuator based on sprayed non-metal electrode and preparation method thereof

A non-metallic, flexible electrical technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the cost Expensive, large-scale manufacturing is hindered, and device drive reliability is affected, achieving the effect of bandwidth guarantee and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: The ionic polymer intermediate layer of the flexible electro-actuator is prepared in the following way:

[0050] 1. Weigh 10g TPU particles on a balance and put them in a Petri dish for use, and at the same time take 30g N, N-dimethylformamide (DMF) solution (according to the density of DMF at this temperature to convert the volume to 31.75mL) in a round-bottom flask and heat it in a water bath pot to 80 °C;

[0051] 2. Add magnetic stirrers to the round bottom flask to stir, and slowly add TPU particles (adding too fast is easy to make the semi-dissolved state of TPU particles piled up at the bottom of the flask, hindering stirring), stirring for about 1 hour until all TPU particles are dissolved in DMF;

[0052] 3. Add 120% (i.e., 12g) of the ionic liquid 1-ethyl-3-methylimidazolium bis (trifluoromethesulfonyl) imide ([EMIM] to the round bottom flask + [TFSI] - ), and magnetically stirred at 80 °C for 12 hours;

[0053] 4. The i-TPU solution made by the above s...

Embodiment 2

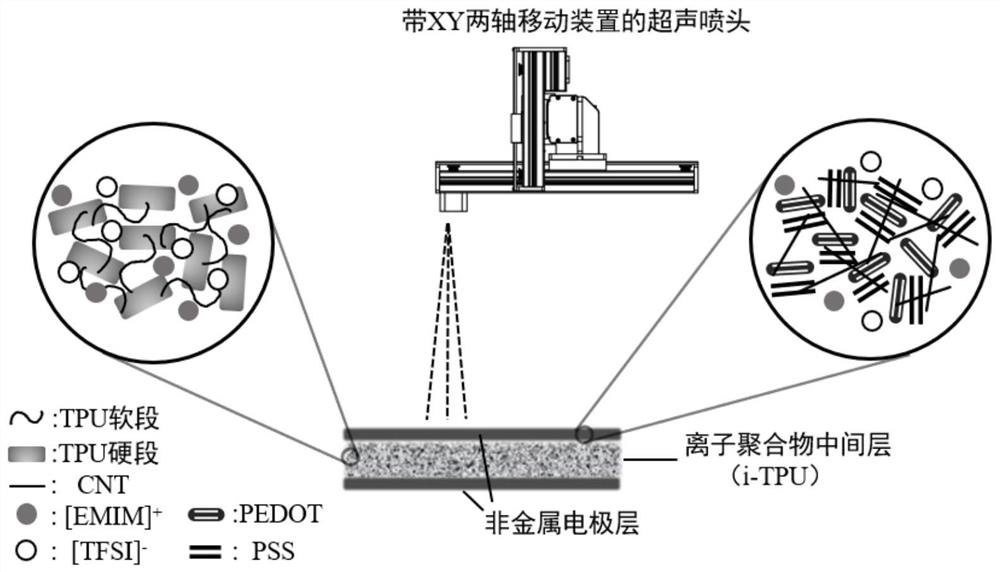

[0056] Example 2: Ultrasonic spray non-metallic electrode layer preparation method of flexible electro actuator is as follows:

[0057]1. Take 30g PEDOT: PSS aqueous dispersion solution, add 1.5g DMSO, 3.5g ethanol and 0.45g of ionic liquid, stir in 40°C water bath for 3 hours;

[0058] 2, weigh 0.13g carbon nanotubes (CNT) on the weighing paper with a balance to set aside, use a small spoon to slowly add CNT to the above-mentioned mixed solution that is being magnetically stirred, continue to stir for 1 hour and then treat with 90W ultrasound for 3 minutes, so that the CNT is evenly dispersed and the non-metallic electrode precursor solution is obtained;

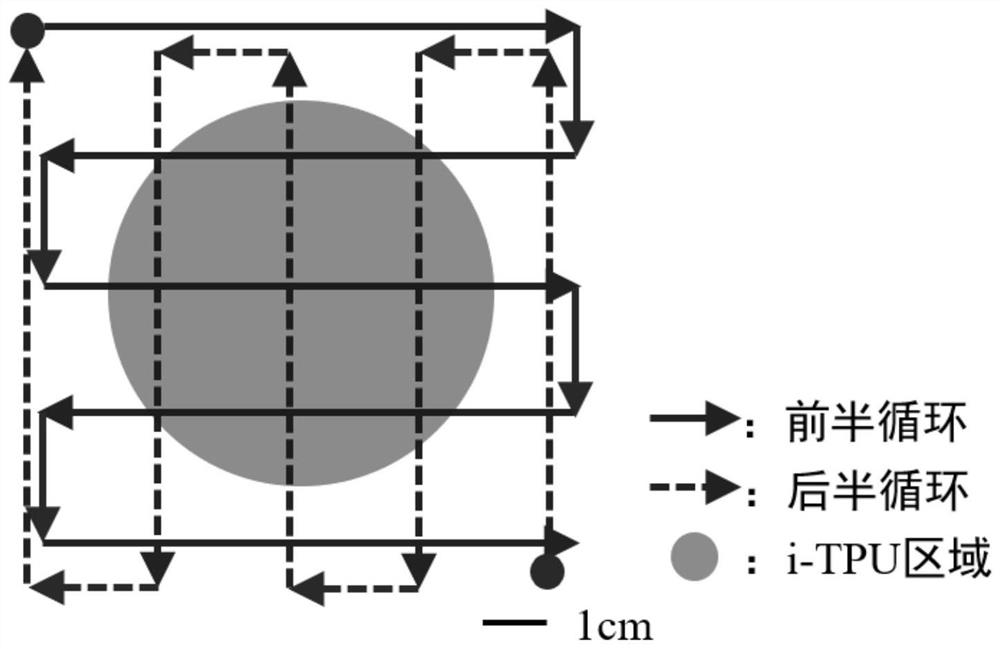

[0059] 3. Use a 5mL syringe to aspirate the non-metallic electrode precursor solution and place it on the propulsion pump, set the propulsion speed to 0.8mL / min, drain the air in the inlet hose after running for a period of time, open the hot table (set temperature is 80 °C), open the compressed nitrogen valve connected to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com