Electrically exfoliated graphene silicon carbon composite material as well as preparation method and application thereof

A silicon-carbon composite material and electro-stripping technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of electron-ion transport path destruction, low diffusion coefficient, unstable solid-state electrolyte interface, etc., and achieve easy mass production. , the effect of high conductivity and excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

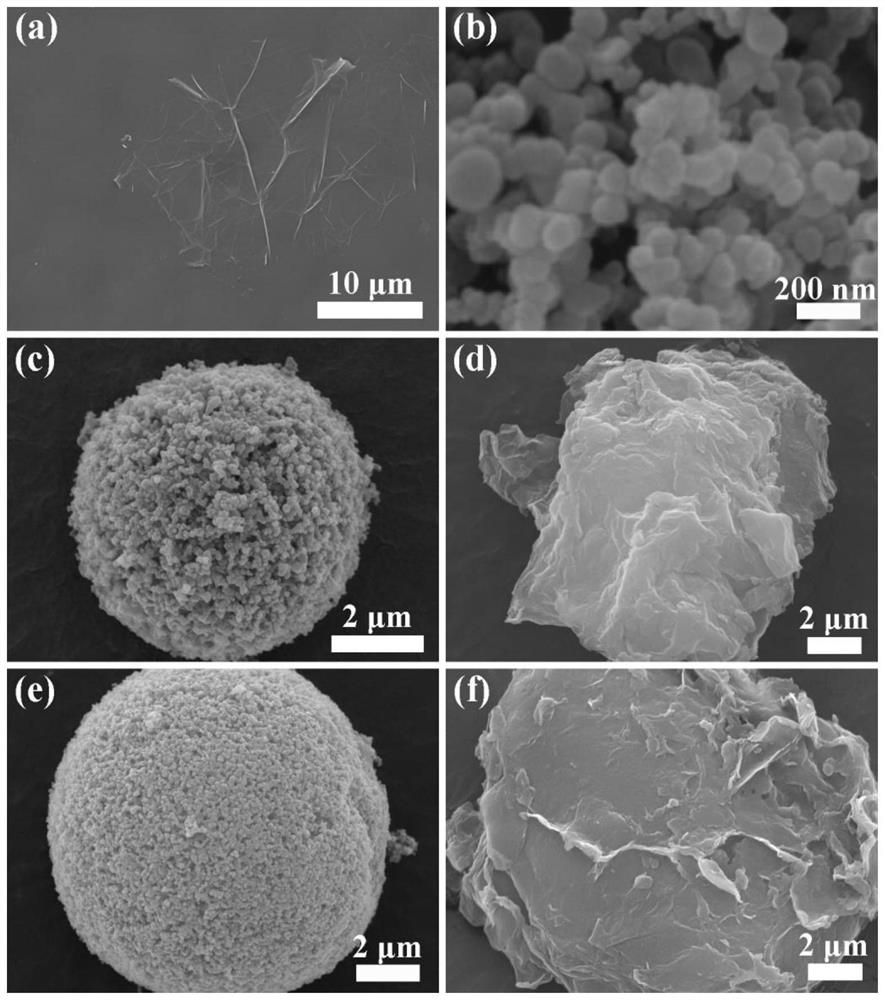

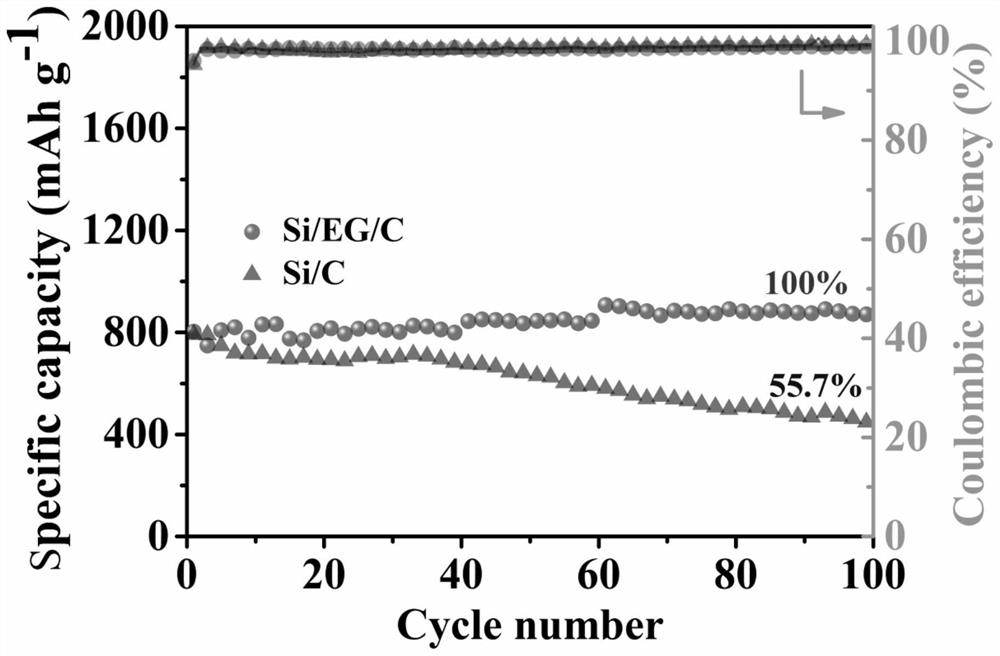

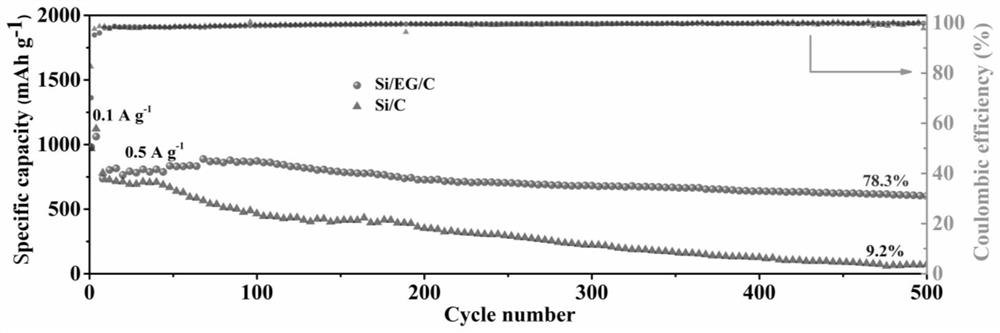

[0043] A kind of electric exfoliation graphene silicon carbon composite material, comprises the steps:

[0044] S100, mixing EG (electroexfoliated graphene), silicon powder, and sucrose according to 1:1.2:0.5 and then ball milling;

[0045] S200, spray drying and granulating the product after ball milling at 120°C;

[0046] S300. Calcining the spray-dried product at a high temperature of 950° C. under an argon atmosphere to obtain a final product Si / EG / C.

Embodiment 2

[0048] A kind of electric exfoliation graphene silicon carbon composite material, comprises the steps:

[0049] S100, mixing EG (electroexfoliated graphene), silicon oxide, and sucrose according to 1:1.5:0.5 and then ball milling;

[0050] S200, spray drying and granulating the product after ball milling at 120°C;

[0051] S300, calcining the spray-dried product at a high temperature of 950° C. under an argon atmosphere to obtain a final product SiO / EG / C.

Embodiment 3

[0053] A kind of electric exfoliation graphene silicon carbon composite material, comprises the steps:

[0054] S100, ball milling after mixing EG (electroexfoliated graphene), silicon powder, and starch according to 1:1.2:0.5;

[0055] S200, spray drying and granulating the product after ball milling at 120°C;

[0056] S300. Calcining the spray-dried product at a high temperature of 950° C. under an argon atmosphere to obtain a final product Si / EG / C.

[0057] Of course, in addition to silicon powder, other alloy-based anode materials that have similar charging and discharging mechanisms and disadvantages to silicon-based materials can also be used, such as tin (Sn)-based materials, aluminum (Al)-based materials, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com