Non-aqueous electrolyte and lithium ion battery containing same

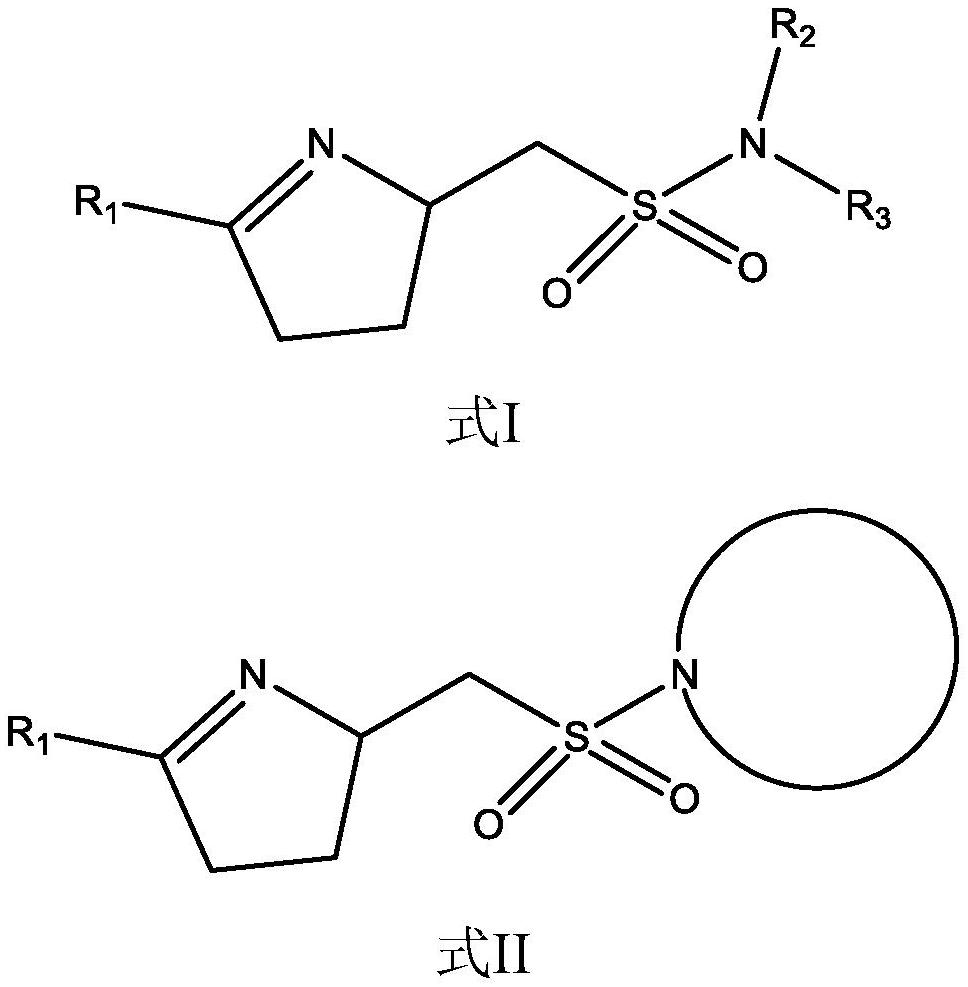

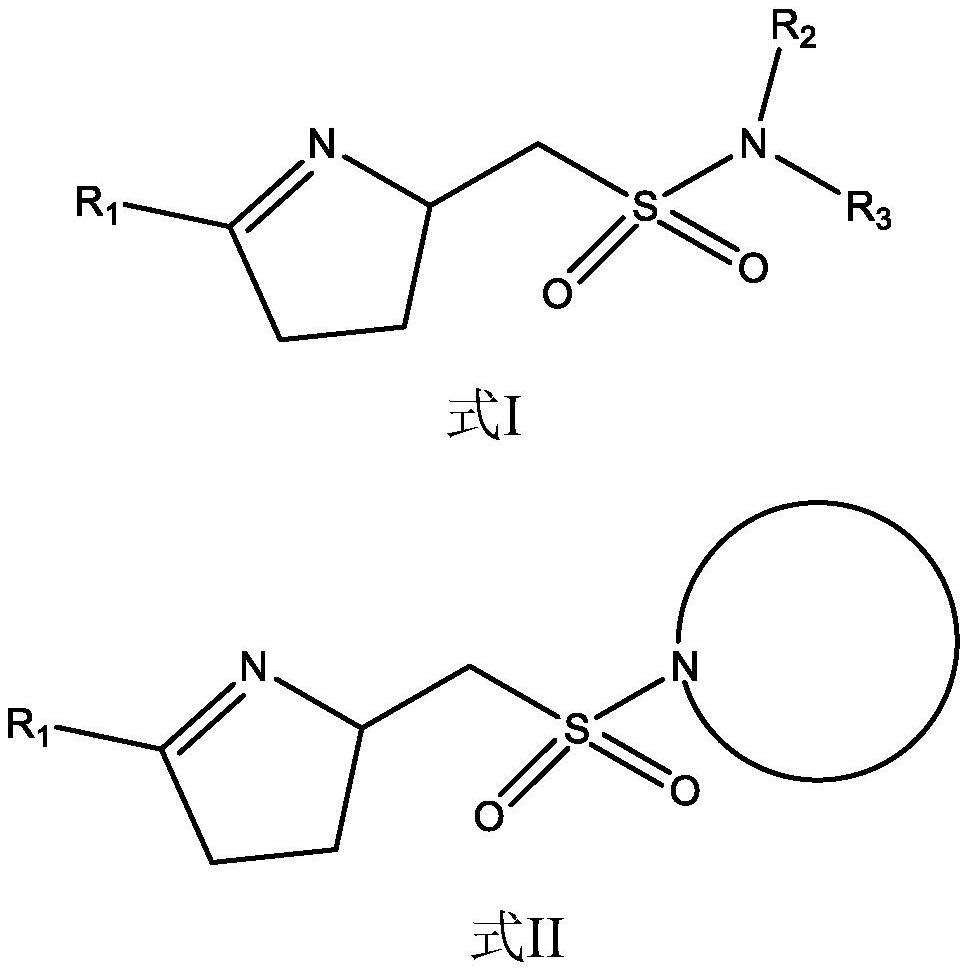

A non-aqueous electrolyte and lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve the problems of active material falling off, destroying the electrolyte function, reducing battery cycle performance and high temperature performance, so as to reduce acidity and reactivity and avoid battery damage. Performance deterioration, effect of suppressing increase in free acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] (1) Preparation of positive electrode sheet

[0074] The positive electrode active material ternary layered nickel-cobalt lithium manganese oxide (Li[Ni 0.8 co 0.1 mn 0.1 ]O 2 ), the binder polyvinylidene fluoride (PVDF), and the conductive agent acetylene black are mixed according to a weight ratio of 95:2:3, N-methylpyrrolidone (NMP) is added, and stirred under the action of a vacuum mixer until the mixed system becomes uniform , positive electrode slurry with good fluidity; the positive electrode slurry is evenly coated on the aluminum foil with a thickness of 10 μm; after the above-mentioned coated aluminum foil is baked in 5 ovens with different temperature gradients, it is then heated at 120 ° C Dry in an oven for 8 hours, and then roll and cut to obtain the desired positive electrode sheet.

[0075] (2) Negative sheet preparation

[0076] Mix the negative electrode silicon-carbon composite material, thickener carboxymethylcellulose sodium (CMC-Na), binder st...

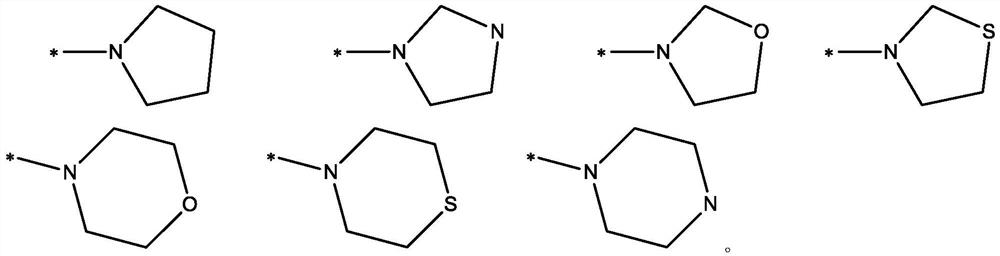

Embodiment 16

[0099] The results of Example 16 show that: when sulfonamide additives are used, the sulfonamide additives can be oxidized on the surface of the positive electrode to form a CEI film with good high temperature stability, so as to inhibit the catalytic oxidation decomposition of the high-nickel positive electrode material to the electrolyte, which helps to improve Normal temperature cycle, high temperature cycle and high temperature storage performance of the battery. In addition, it can be seen from the comparison of Example 16 with Examples 6 and 12-15 that the cooperation of sulfonamide additives and ester additives not only suppresses the increase in the acidity of the electrolyte, but also reduces the ester additives to form mechanical properties on the surface of the negative electrode. A good SEI film, the two cooperate with each other to further improve the normal temperature cycle, high temperature cycle and high temperature storage performance of the battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com