COMPOSITION COMPRISING SECRETATING IgA AND PROBIOTIC BACTERIA

A technology of composition and probiotics, applied in the direction of medical preparations containing active ingredients, drug combinations, antibody medical ingredients, etc., can solve problems affecting the efficiency of the compound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0192] Embodiment 1: according to the method of the present invention

[0193]Raw milk is received from a Swiss farm and centrifuged at 15°C to obtain crude skim milk. Using a reverse osmosis (RO) concentration unit (Tetra Alcross RO, with spiral membrane Alfa Laval RO98pHt-3838 / 30 - Tetra Pak, Lund, Sweden), the crude Skim milk concentrated to 24% dry matter. The 24% RO skim milk was preheated to 55°C in a plate heat exchanger and heated to 83°C using direct steam injection. After passing through an insulated tube providing an average residence time of 6 seconds, the RO skim milk was flash cooled to 55°C using a flash evaporator common in the dairy industry. The RO skim milk was further cooled to 5°C in a plate heat exchanger and then spray dried on an open top spray dryer as described in US2353495 under mild conditions without preheating to produce RO skim milk powder. Egron exhaust temperature and relative humidity are 12% and 65°C. RO skim milk powder contained 139 μ...

Embodiment 2

[0196] Example 2: Effect of microfiltered skim milk on SIgA content

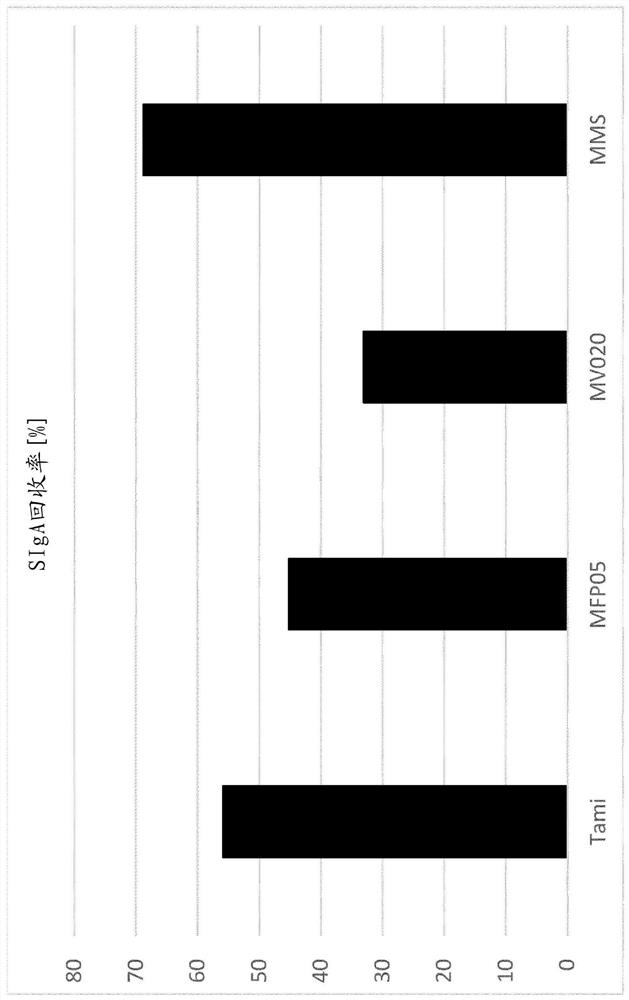

[0197] Crude skim milk (8.0%-8.7% total solids) and reverse osmosis (RO) skim milk (approximately 24% total solids) were used for these experiments. The milk was subjected to microfiltration (MF) using different membranes at temperatures between 52°C and 55°C. SIgA content in pre-filtered and post-filtered milk was measured by ELISA at different stages as described above. The percentage of SIgA in the permeate after microfiltration (SIgA yield [%]) was calculated relative to the amount of SIgA in the milk before filtration. The milk was also assessed for microbial contamination and the log reduction in bacterial content (total plate count reduction [log]) calculated. The results are provided in Table 2 and Figure 3 below.

[0198] The experiment with the membrane that gave the best results was repeated at a temperature of 14°C for evaluating the effect of temperature on SIgA retention and reduction of m...

Embodiment 3

[0208] Example 3: Comparison of different conditions for heat treatment of reverse osmosis (RO) skim milk

[0209] Raw milk was centrifuged at 15°C to obtain crude skim milk. Crude skim milk was concentrated from 9% dry matter to 22.9% dry matter at 15°C using a reverse osmosis (RO) concentration unit (see Example 1). Four different thermal treatments of RO skim milk using direct steam injection and rapid cooling:

[0210] - Sample 1: 74°C / 103 seconds

[0211] - Sample 2: 83°C / 6 sec

[0212] - Sample 3: 87°C / 2 sec

[0213] - Sample 4: 90°C / 0.96 sec

[0214] The pasteurized liquid RO skim milk was cooled to 5°C and the cold concentrate was spray dried.

[0215] SIgA molecules present in raw RO skim milk (reference), SIgA molecules present in heat-treated RO skim milk (sample 1 to sample 4), and in final powders obtained from sample 1 to sample 4 were assessed by ELISA SIgA molecules present. Quantification of SIgA bioactivity in heat-treated RO skim milk and in the fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com