Spheroidized carbonaceous negative electrode active material, method for producing same, and negative electrode and lithium secondary battery comprising same

A negative electrode active material and spheroidization technology, which is applied in secondary batteries, electrode manufacturing, active material electrodes, etc., can solve problems such as electrolyte damage, gas generation, and high-temperature storage characteristics reduction, and achieve reduced internal stress and high capacity retention. , The effect of improving the expansion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

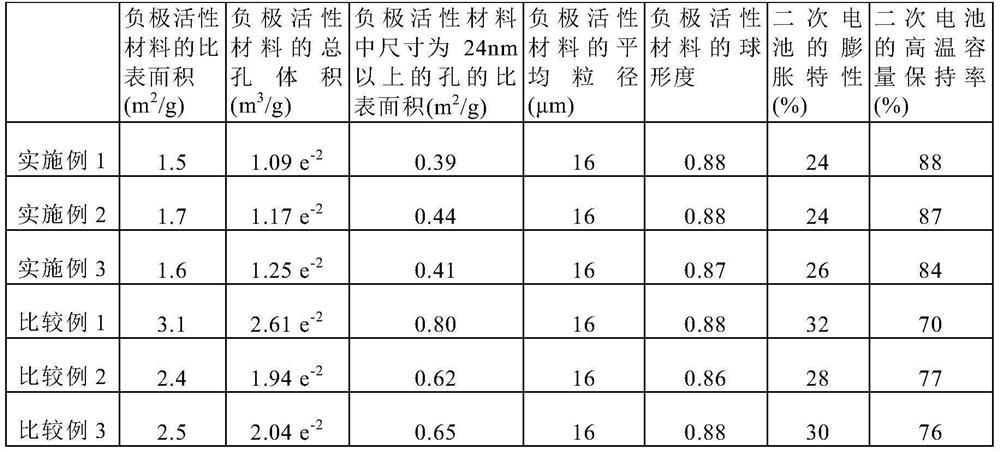

Embodiment 1

[0115] (Preparation of spheroidized carbonaceous negative electrode active material)

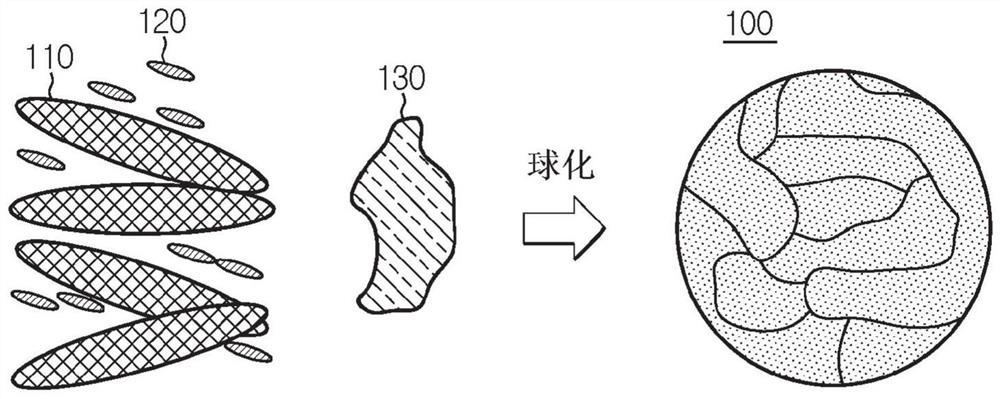

[0116] Flake graphite with an average particle diameter of 70 μm, solid pitch and liquid pitch with an average particle diameter of 5 μm were prepared in a weight ratio of 95:4:1, mixed by using a ball mill, and mixed by using a reverse jet mill (Hosokawa Micron, JP ) spheroidization to obtain spheroidized granulated particles. Then, 100 parts by weight of the obtained spheroidized granulated particles were mixed with 5 parts by weight of solid pitch as a carbon coating material, and the resulting mixture was carbonized at a temperature of 1,150° C. for 24 hours by using a ball mill to obtain a carbon-coated Spheroidized granulated particles of cloth.

[0117] Then, the carbon-coated spheroidized granulated particles were heat-treated at a temperature of 1,350° C. for 12 hours.

[0118] Then, the heat-treated product is disintegrated to obtain a spheroidized carbonaceous negative electrode...

Embodiment 2

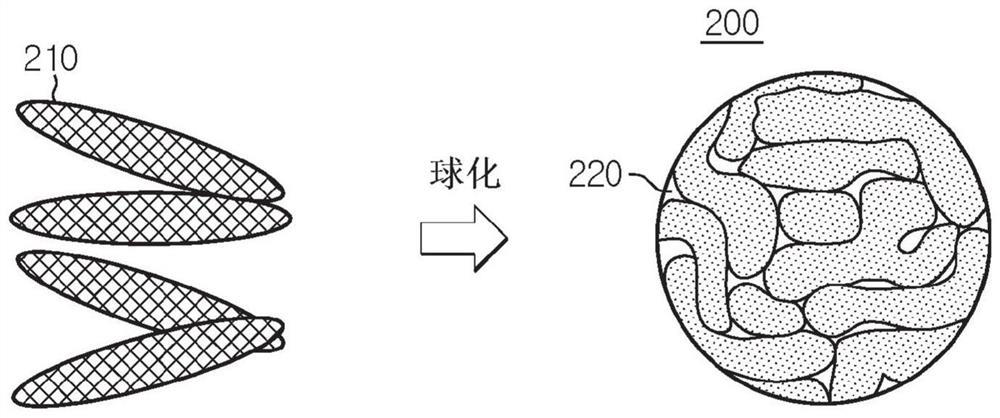

[0124] The spheroidized carbonaceous negative electrode active material was obtained in the same manner as in Example 1, except that flake graphite, solid pitch and liquid pitch were prepared in a weight ratio of 96:3:1.

[0125] In addition, a secondary battery was obtained in the same manner as in Example 1 except that the negative electrode active material obtained as described above was used.

Embodiment 3

[0127] The spheroidized carbonaceous negative electrode active material was obtained in the same manner as in Example 1, except that flake graphite, solid pitch and liquid pitch were prepared in a weight ratio of 94:5:1.

[0128] In addition, a secondary battery was obtained in the same manner as in Example 1 except that the negative electrode active material obtained as described above was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com