High-fracture-toughness thermal barrier coating material of high-entropy rare earth aluminate toughened high-entropy rare earth zirconate as well as preparation method and application of high-fracture-toughness thermal barrier coating material

A thermal barrier coating and aluminate technology, applied in the field of composite materials, can solve the problems of unsatisfactory mechanical properties such as fracture toughness of high-entropy rare earth zirconate materials, and achieve good high-temperature phase stability, broad application prospects, high The effect of fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

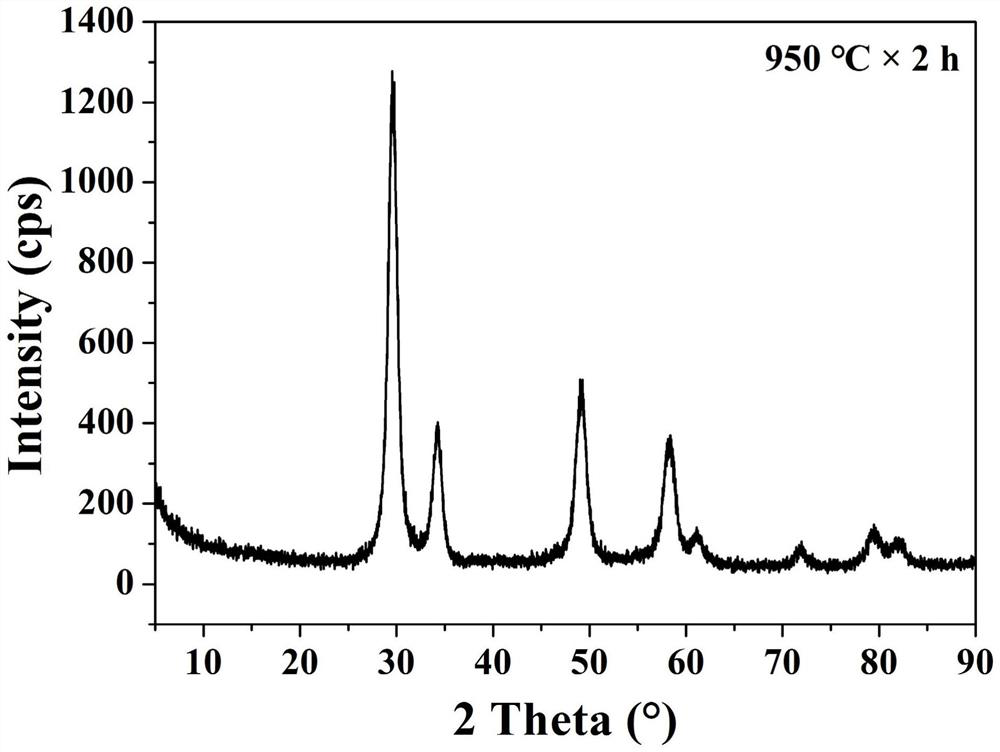

[0030] A high-entropy rare earth aluminate toughened high-entropy rare earth zirconate high fracture toughness thermal barrier coating material, the chemical composition is x[nRE 1 / n AlO 3 ]-(1-x)[n(RE 1 / n ) 2 Zr 2 o 7 ] (00.2 AlO 3 ]-0.9[5(RE 0.2 ) 2 Zr 2 o 7 ], when RE is preferably La, Sm, Eu, Gd, Yb, its chemical composition is: 0.1 (La 0.2 SM 0.2 Eu 0.2 Gd 0.2 Yb 0.2 )AlO 3 -0.9(La 0.2 SM 0.2 Eu 0.2 Gd 0.2 Yb 0.2 ) 2 Zr 2 o 7 , the preparation method of the high-entropy rare earth aluminate toughened high-entropy rare earth zirconate high fracture toughness thermal barrier coating material comprises:

[0031] (1) Preparation of mixed solution

[0032] Weigh 4.1273g of lanthanum oxide, 4.4169g of samarium oxide, 4.4578g of europium oxide, 4.5917g of gadolinium oxide, and 4.9917g of ytterbium oxide, respectively dissolve them in nitric acid, stir at 400rpm, and at a temperature of 65°C, wait until all oxides are dissolved and clarified before mixing ...

Embodiment 2

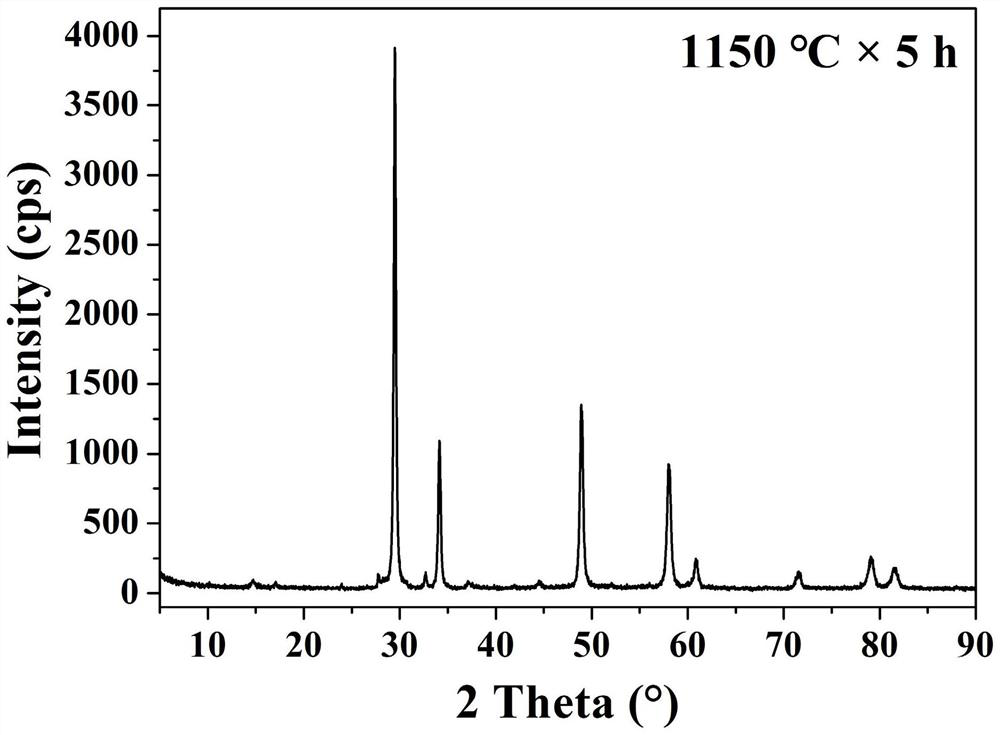

[0042] A high-entropy rare earth aluminate toughened high-entropy rare earth zirconate high fracture toughness thermal barrier coating material, the chemical composition is x[nRE 1 / n AlO 3 ]-(1-x)[n(RE 1 / n ) 2 Zr 2 o 7 ] (00.2 AlO 3]-0.8[5(RE 0.2 ) 2 Zr 2 o 7 ], when RE is preferably La, Sm, Eu, Gd, Yb, its chemical composition is: 0.2 (La 0.2 SM 0.2 Eu 0.2 Gd 0.2 Yb 0.2 )AlO 3 -0.8(La 0.2 SM 0.2 Eu 0.2 Gd 0.2 Yb 0.2 ) 2 Zr 2 o 7 , the preparation method of the high-entropy rare earth aluminate toughened high-entropy rare earth zirconate high fracture toughness thermal barrier coating material comprises:

[0043] (1) Preparation of mixed solution

[0044] Weigh 3.9101g of lanthanum oxide, 4.1844g of samarium oxide, 4.2232g of europium oxide, 4.3500g of gadolinium oxide, and 4.7290g of ytterbium oxide, respectively dissolve them in nitric acid, stir at 600rpm, and at a temperature of 85°C, wait until all oxides are dissolved and clarified before mixing ,...

Embodiment 3

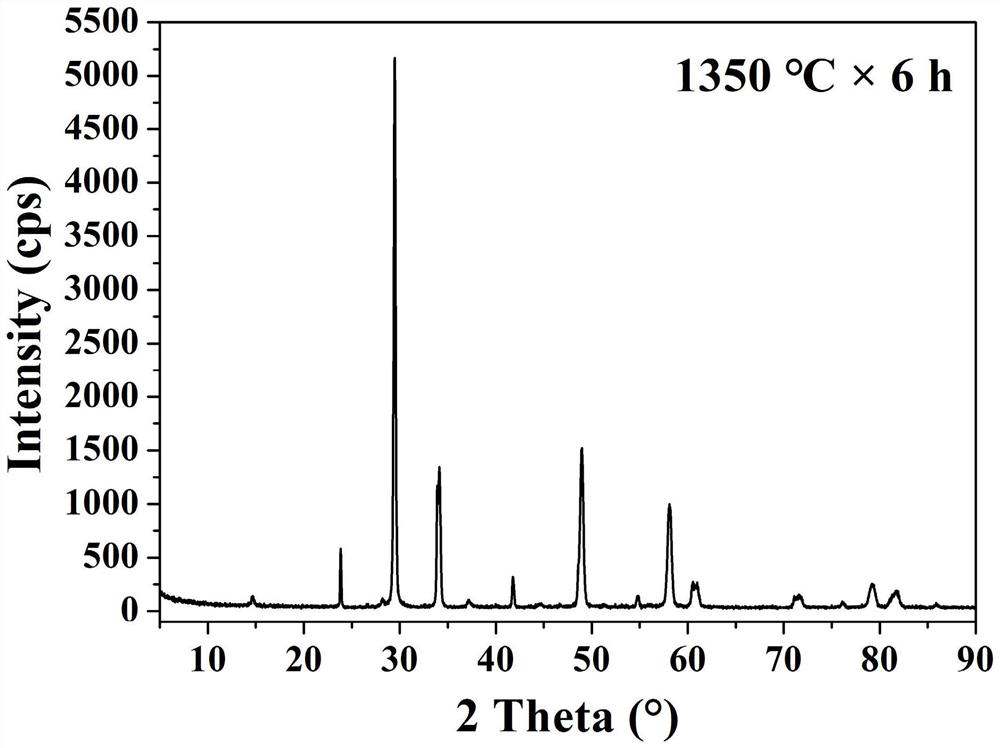

[0054] A high-entropy rare earth aluminate toughened high-entropy rare earth zirconate high fracture toughness thermal barrier coating material, the chemical composition is x[nRE 1 / n AlO 3 ]-(1-x)[n(RE 1 / n ) 2 Zr 2 o 7 ] (00.2 AlO 3 ]-0.7[5(RE 0.2 ) 2 Zr 2 o 7 ], when RE is preferably La, Sm, Eu, Gd, Yb, its chemical composition is: 0.3 (La 0.2 SM 0.2 Eu 0.2 Gd 0.2 Yb 0.2 )AlO 3 -0.7(La 0.2 SM 0.2 Eu 0.2 Gd 0.2 Yb 0.2 ) 2 Zr 2 o 7 , the preparation method of the high-entropy rare earth aluminate toughened high-entropy rare earth zirconate high fracture toughness thermal barrier coating material comprises:

[0055] (1) Preparation of mixed solution

[0056] Weigh 3.6929g of lanthanum oxide, 3.9519g of samarium oxide, 3.9885g of europium oxide, 4.1083g of gadolinium oxide, and 4.4662g of ytterbium oxide, respectively dissolve them in nitric acid, stir at 550rpm, and at a temperature of 105°C, wait until all oxides are dissolved and clarified before mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com