Method for removing glycidyl ester, 3-chloropropanediol and esters thereof from natural vitamin E and obtained product

A technology of natural vitamins and glycidyl esters, which is applied in the food field, can solve the problems of large oil loss, low content and weak specificity, and achieve the effects of small material loss, simple process and strong adsorption specificity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Embodiment 1: remove glycidyl ester and 3-chloropropanediol and its ester from natural vitamin E

[0099] The implementation steps of this embodiment are as follows:

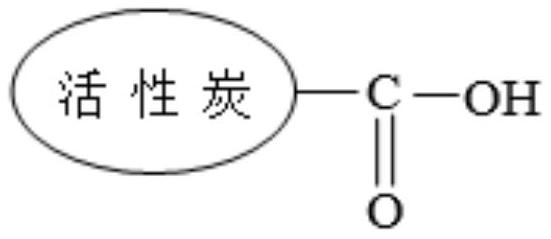

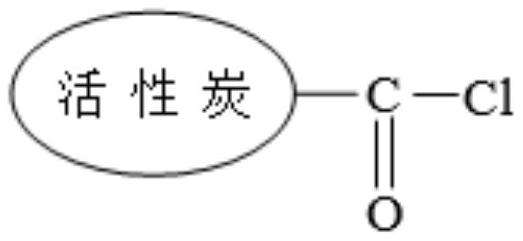

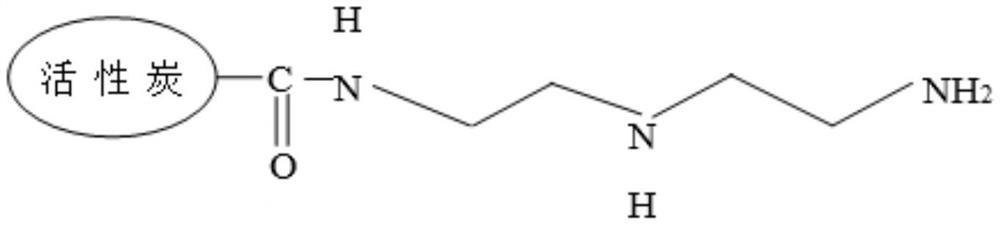

[0100] A. Activated carbon acid treatment

[0101] According to the ratio of activated carbon in grams and dilute nitric acid aqueous solution in milliliters is 1:4, adding concentration is 3% dilute nitric acid aqueous solution by weight in the 60 mesh activated carbon sold by Shanghai Activated Carbon Factory Co., Ltd. under the trade name wood powder, Stir at a temperature of 24°C for 25 minutes, filter, and then repeat the treatment once in the same manner;

[0102] Then, according to the ratio of activated carbon in grams to concentrated nitric acid aqueous solution in milliliters is 1:3, add concentrated nitric acid aqueous solution with a concentration of 15% by weight to the activated carbon, stir at a temperature of 84°C for 40min, filter, and treat in this way The activated carbon is washed wi...

Embodiment 2

[0113] Embodiment 2: remove glycidyl ester and 3-chloropropanediol and its ester from natural vitamin E

[0114] The implementation steps of this embodiment are as follows:

[0115] A. Activated carbon acid treatment

[0116]According to the ratio of activated carbon in grams and dilute nitric acid aqueous solution in milliliters is 1:3, adding concentration is 1% dilute nitric acid aqueous solution by weight in the 80 mesh activated carbon sold by Shanghai Activated Carbon Factory Co., Ltd. under the trade name wood powder, Stir at a temperature of 20°C for 20 minutes, filter, and then repeat the treatment once in the same way;

[0117] Then, according to the ratio of activated carbon in grams to concentrated nitric acid aqueous solution in milliliters is 1:5, add concentrated nitric acid aqueous solution with a concentration of 10% by weight to the activated carbon, stir at a temperature of 80°C for 30 minutes, filter, and treat in this way The activated carbon is washed w...

Embodiment 3

[0128] Embodiment 3: remove glycidyl ester and 3-chloropropanediol and its ester from natural vitamin E

[0129] The implementation steps of this embodiment are as follows:

[0130] A. Activated carbon acid treatment

[0131] According to the ratio of activated carbon in grams and dilute nitric acid aqueous solution in milliliters is 1:4, adding concentration is 5% dilute nitric acid aqueous solution by weight in the 60 mesh activated carbon sold by Shanghai Activated Carbon Factory Co., Ltd. under the trade name wood powder, Stir at a temperature of 30°C for 30 minutes, filter, and then repeat the treatment once in the same way;

[0132] Then, according to the ratio of activated carbon in grams to concentrated nitric acid aqueous solution in milliliters is 1:4, add concentrated nitric acid aqueous solution with a concentration of 12% by weight to the activated carbon, stir at a temperature of 82°C for 60 minutes, filter, and treat in this way The activated carbon is washed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com