High-temperature-stability sodium bismuth titanate-based dielectric energy storage ceramic material and preparation method thereof

A bismuth sodium titanate-based, ceramic material technology, applied in the direction of fixed capacitor dielectrics, fixed capacitors, fixed capacitor parts, etc., to achieve excellent performance, strong energy storage capacity, and the effect of weakening ferroelectricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

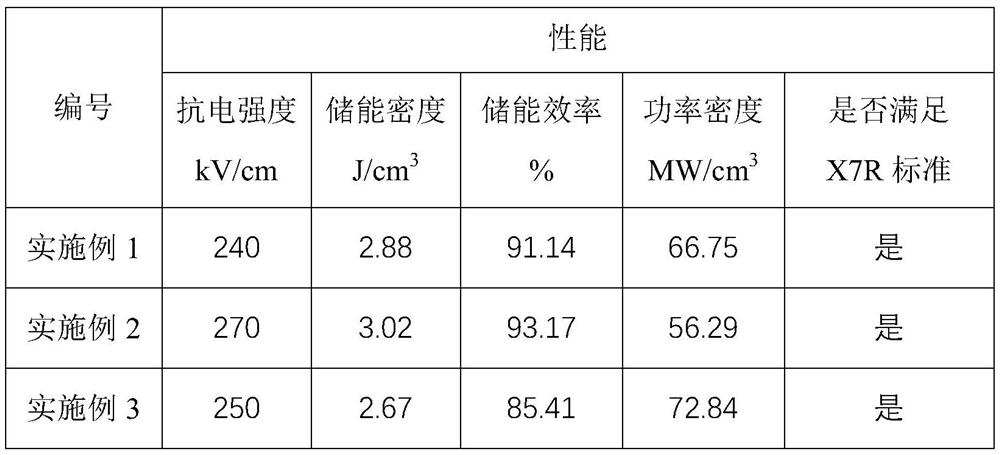

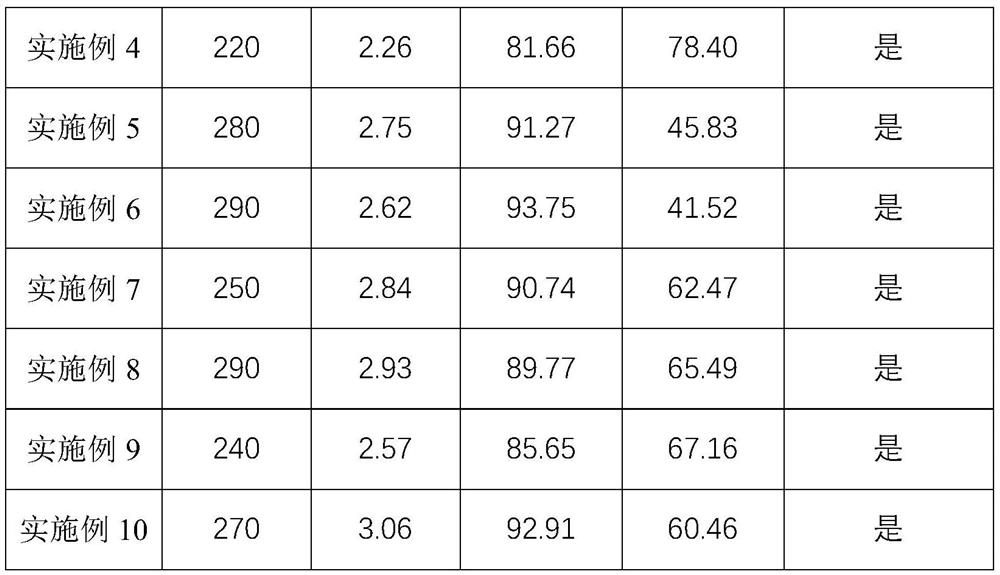

Examples

preparation example Construction

[0022] The preparation method of described ceramic material comprises the following steps:

[0023] Step 1: Select from Na with a purity greater than 98% 2 CO 3 、 Bi 2 o 3 、BaCO 3 , SrCO3 、TiO 2 , ZnO, Ta 2 o 5 Powder, according to the general chemical formula Na 0.5 Bi 0.5 TiO 3 -xBaTiO 3 -ySrTiO 3 -zZnTa 2 o 6 , 0≤x≤0.1, 0.2≤y≤0.5, 0≤z≤0.2 ingredients;

[0024] Step 2: Put the powder prepared in step 1 into a nylon ball mill tank, use zirconium balls and absolute ethanol as the ball milling medium, and according to the mass ratio of mixture: grinding ball: absolute ethanol is 1: (4 ~ 8): The ratio of (1~3) is ball milled for 3~10 hours to obtain a uniformly mixed ceramic powder, and then dried at a temperature of 60~120°C, sieved through a sieve of 80~120 mesh, and calcined at a temperature of 700~1000°C for 2~ 6h, to obtain the calcined material;

[0025] Step 3: The calcined material obtained in step 2 is ball-milled for 3-10 hours with the mass ratio of ca...

Embodiment 1

[0028] Weigh 3.5012g of Na 2 CO 3 , 15.6220g Bi 2 o 3 , 0g of BaCO 3 , 13.8642g of SrCO 3 , 18.0018g of TiO 2 , 0.7643g of ZnO and 4.1499g of Ta 2 o 5 , to get a mixture;

[0029] Use zirconia balls as the ball milling medium for the obtained mixture, and perform ball milling according to the mass ratio of mixture: ball: absolute ethanol of 1:5:2 to obtain a uniformly mixed ceramic powder, and then dry it at 70°C After sieving through a 100-mesh sieve, calcining at 900°C for 4 hours to obtain pre-fired material;

[0030] After the obtained calcined material is crushed, zirconia balls are used as the ball milling medium, and the mass ratio of mixture: balls: absolute ethanol is 1:5:2 for ball milling for 6 hours, and then dried at 70°C , using polyvinyl alcohol solution with a concentration of 2%-10% as a binder to granulate, and press molding under a pressure of 10MPa for 10s to obtain a green body;

[0031] The obtained green body was sintered at a temperature of 12...

Embodiment 2

[0033] Weigh 3.3891g of Na 2 CO 3 , 15.1219g Bi 2 o 3 , 0g of BaCO 3 , 13.6644g of SrCO 3 , 17.5575g of TiO 2 , 0.9415g of ZnO and 5.1126g of Ta 2 o 5 , to get a mixture;

[0034] Use zirconia balls as the ball milling medium for the obtained mixture, and perform ball milling according to the mass ratio of mixture: ball: absolute ethanol of 1:5:2 to obtain a uniformly mixed ceramic powder, and then dry it at 70°C After sieving through a 100-mesh sieve, calcining at 900°C for 4 hours to obtain pre-fired material;

[0035] After the obtained calcined material is crushed, zirconia balls are used as the ball milling medium, and the mass ratio of mixture: balls: absolute ethanol is 1:5:2 for ball milling for 6 hours, and then dried at 70°C , using polyvinyl alcohol solution with a concentration of 2%-10% as a binder to granulate, and press molding under a pressure of 10MPa for 10s to obtain a green body;

[0036] The obtained green body was sintered at a temperature of 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com