Inorganic reflective heat-insulation light ceramic colored stone coating and preparation method thereof

A heat-insulating aggregate and coating technology, applied in the direction of reflective/signal coating, thixotropic coating, coating, etc., can solve the problems of non-reflective heat insulation, etc., and achieve the effects of color matching, consumption reduction, and low VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0022] According to an embodiment of the present invention, the drag reducing agent is polyacrylamide containing hydrophobic structural units, preferably, the drag reducing agent is obtained by micellar copolymerization of acrylamide and a hydrophobic monomer; more preferably, the drag reducing agent is obtained by micellar copolymerization. The drag reducing agent is obtained by micellar copolymerization of acrylamide and octylphenol polyoxyethylene (4) ether acrylate in an aqueous solution of sodium lauryl sulfate; further preferably, the drag reducing agent is Slip agent S18.

[0023] The drag reducing agent used in the present invention is preferably an anionic polymer with a reversible cross-linked network structure and a molecular weight of 4 to 6 million. This type of drag reducer has good mechanical properties, unusual swelling behavior, transparency, resilience and obvious thermoelastic behavior, and its unique reversible cross-linked network structure endows it with...

Embodiment 1

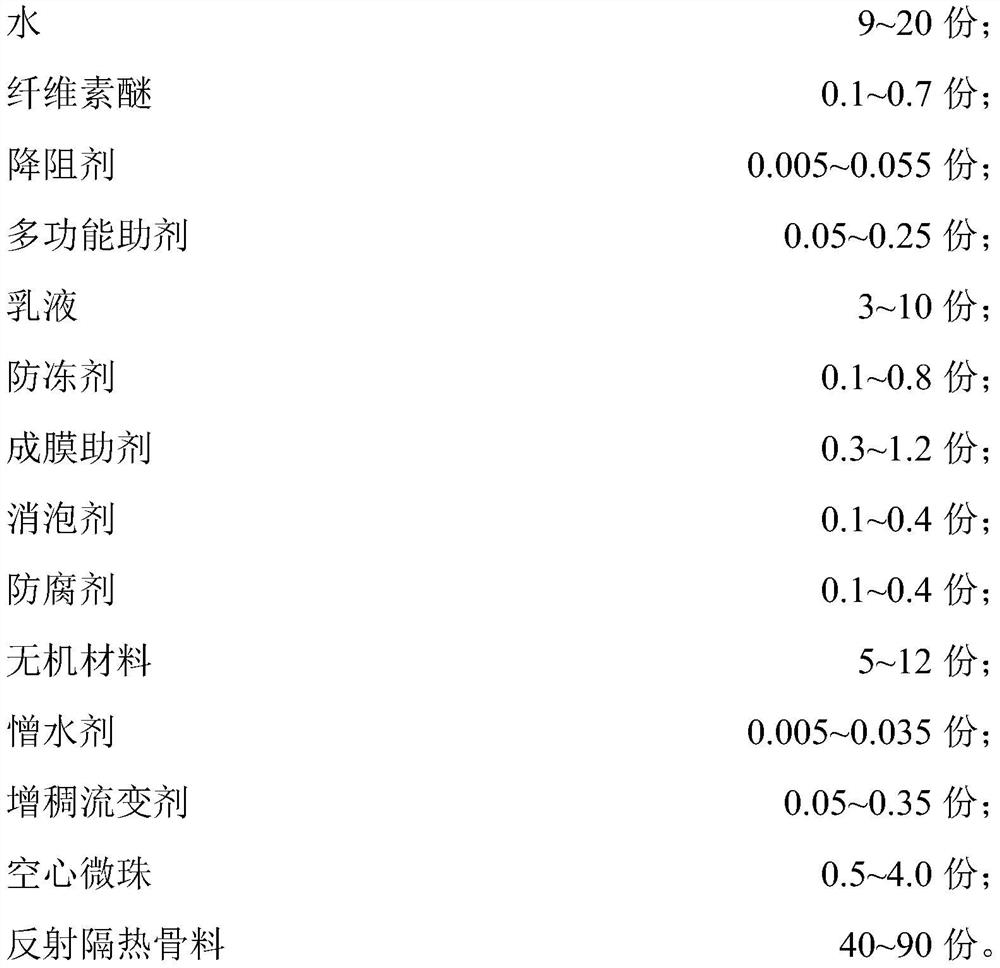

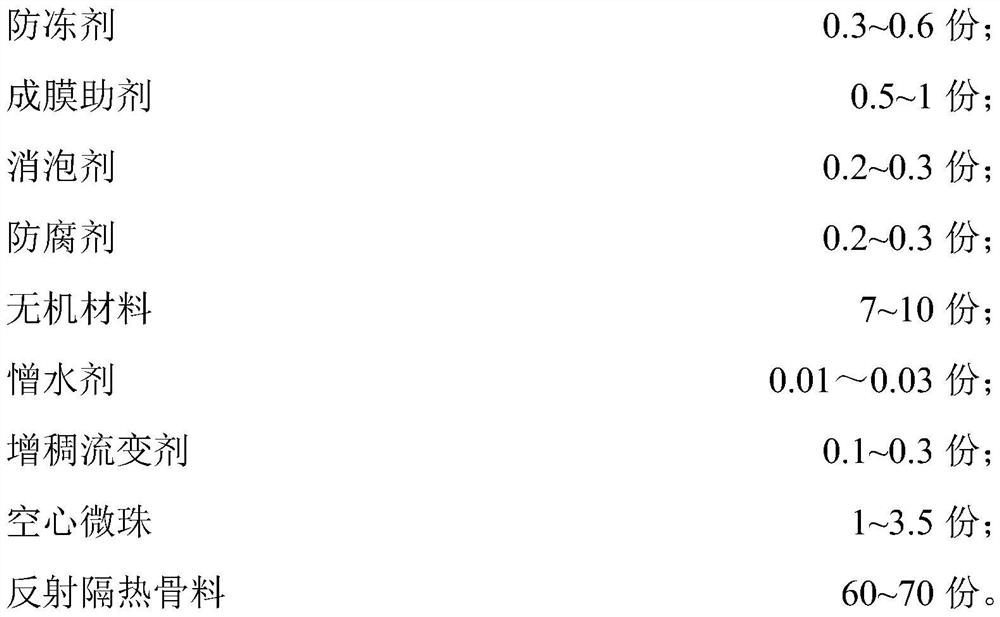

[0067] The inorganic reflective and heat-insulating light-weight ceramic stone paint provided in this embodiment, in proportion by weight, includes:

[0068] 11.95 parts of water, 0.3 part of cellulose ether, 0.02 part of drag reducing agent, 0.15 part of multifunctional auxiliary, 6 parts of emulsion, 0.3 part of antifreeze, 0.6 part of film-forming aid, 0.2 part of defoamer, 0.2 part of preservative, 9 parts of inorganic materials, 0.03 parts of water repellent, 0.25 parts of thickening rheological agent, 1 part of hollow microbeads, and 70 parts of reflective and heat-insulating aggregates. The preparation method is as follows:

[0069] (1) First add deionized water into the container, then at 300-500rpm rotating speed, slowly add 0.3 parts of cellulose ether for several times, and stir for 3-5min;

[0070] (2) then under the rotating speed of 600-800rpm, slowly add 0.02 parts of drag reducing agent for many times, and stir for 5-8min;

[0071] (3) Increase the rotation sp...

Embodiment 2

[0074] The inorganic reflective and heat-insulating light-weight ceramic stone paint provided in this embodiment, in proportion by weight, includes:

[0075] 11.45 parts of water, 0.3 parts of cellulose ether, 0.03 parts of drag reducing agent, 0.15 parts of multifunctional additives, 6 parts of emulsion, 0.3 parts of antifreeze, 0.6 parts of film-forming aids, 0.2 parts of defoamer, 0.2 parts of preservatives, 9 parts of inorganic materials, 0.02 parts of water repellent, 0.25 parts of thickening rheological agent, 1.5 parts of hollow microbeads, and 70 parts of reflective heat-insulating aggregates. The preparation method is as follows:

[0076] (1) First add deionized water into the container, then at 300-500rpm rotating speed, slowly add 0.3 parts of cellulose ether for several times, and stir for 3-5min;

[0077] (2) then under the rotating speed of 600-800rpm, slowly add 0.02 parts of drag reducing agent for many times, and stir for 5-8min;

[0078] (3) Increase the rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com