Rare earth ion doped strontium silicate fluorescent powder and preparation method thereof

A rare earth ion and phosphor technology, applied in chemical instruments and methods, luminescent materials, photovoltaic power generation, etc., can solve the problems of weak absorption and limited practical application, and achieve the effects of convenient operation, improved energy utilization efficiency, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the rare earth ion-doped strontium silicate fluorescent powder of the present invention is synthesized by a solid-phase method, and comprises the following steps:

[0030] Step 1) According to the general chemical formula Sr 2-z Ce 0.04 Tb 0.06 Yb z SiO 4 The stoichiometric ratio of each element was weighed to take the corresponding SrCO 3 (A.R.), SiO 2 (A.R.), CeO 2 (99.99%), Tb 4 O 7 (99.99%), Yb 2 O 3 (99.99%), and a small amount of flux;

[0031] Step 2) Place the powder obtained by weighing in step 1) into a container, add an appropriate amount of alcohol to fully grind and mix, and then place it in a high-temperature crucible;

[0032] The above-mentioned container may be an agate mortar, and the high temperature crucible may be a high temperature alumina crucible.

[0033]Step 3) Bury the cover of the high-temperature alumina crucible into the carbon powder environment, place it in a high-temperature furnace and set a program...

Embodiment 1

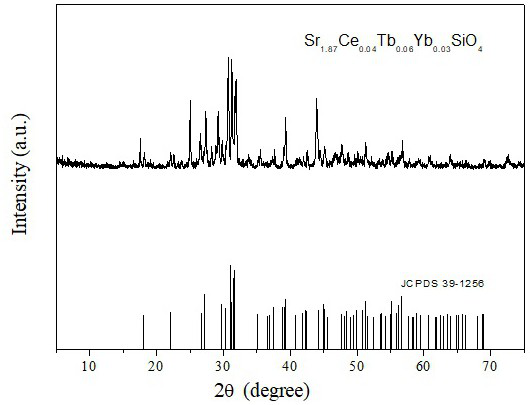

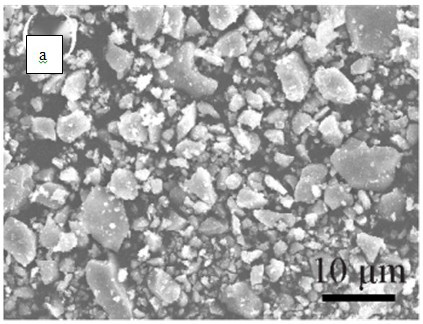

[0041] The chemical composition formula of this embodiment is Sr 1.87 Ce 0.04 Tb 0.06 Yb 0.03 SiO 4 The specific preparation method of the down-conversion phosphor is as follows:

[0042] According to the chemical composition formula Sr 1.87 Ce 0.04 Tb 0.06 Yb 0.03 SiO 4 , according to the stoichiometric ratio, respectively weigh SrCO 3 (A.R.), SiO 2 (A.R.), CeO 2 (99.99%), Tb 4 O 7 (99.99%), Yb 2 O 3 (99.99%), add 1wt% of H 3 BO 3 Put it in an agate mortar and add an appropriate amount of anhydrous ethanol to grind for 30 minutes. After it is dry, scrape off the powder attached to the mortar wall, dry grind for 30 minutes, and then place it in a high-temperature alumina crucible ①, put the crucible ① Buried in a high-temperature alumina crucible ② containing carbon powder, placed in a box furnace, heated to 1100 °C at a heating rate of 5 °C / min, kept for 3 hours, cooled to room temperature with the furnace, and the sample was re-ground into powder , and fina...

Embodiment 2 to Embodiment 5

[0047] The required raw materials were weighed according to the chemical composition formula and stoichiometric ratio in Table 1. The preparation method was the same as that in Example 1. The chemical composition, sintering temperature, sintering time, emission spectrum, Tb 3+ Fluorescence lifetime parameters are listed in Table 1.

[0048] Table 1

[0049]

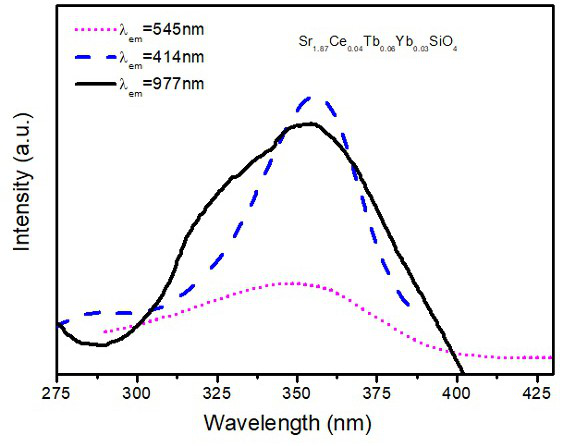

[0050] The phosphors prepared in Examples 1-5 of the present invention, Ce 3+ , Tb 3+ and Yb 3+ The main emission peak varies with Yb 3+ The relative intensity change diagram of the content change is as follows Figure 5 shown. Depend on Figure 5 It can be seen that when Ce 3+ and Tb 3+ When the concentration is constant, with the Yb 3+ The position of each emission peak is basically unchanged, but the intensity changes obviously. Ce 3+ and Tb 3+ The intensity of the emission peak gradually decreases, but Yb 3+ The intensity of the emission peak (977 nm) of the ionic transition gradually increases. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com