Glass body melting gasification furnace, gasification system and gasification method

A melting gasification furnace, melting gasification technology, applied in glass furnace equipment, gasification process, glass production, etc., can solve the problems of harmless treatment, achieve the effects of reducing heat loss, efficient shunting, and reducing the height of the frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

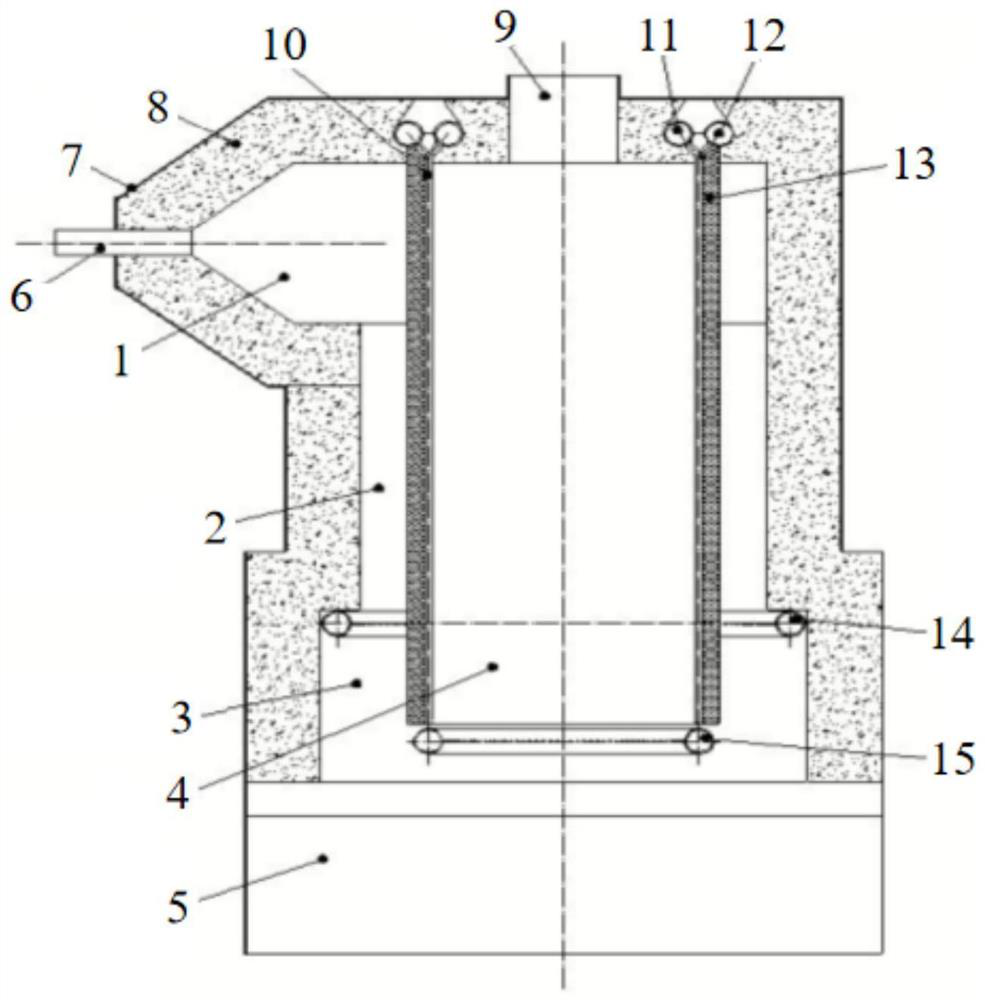

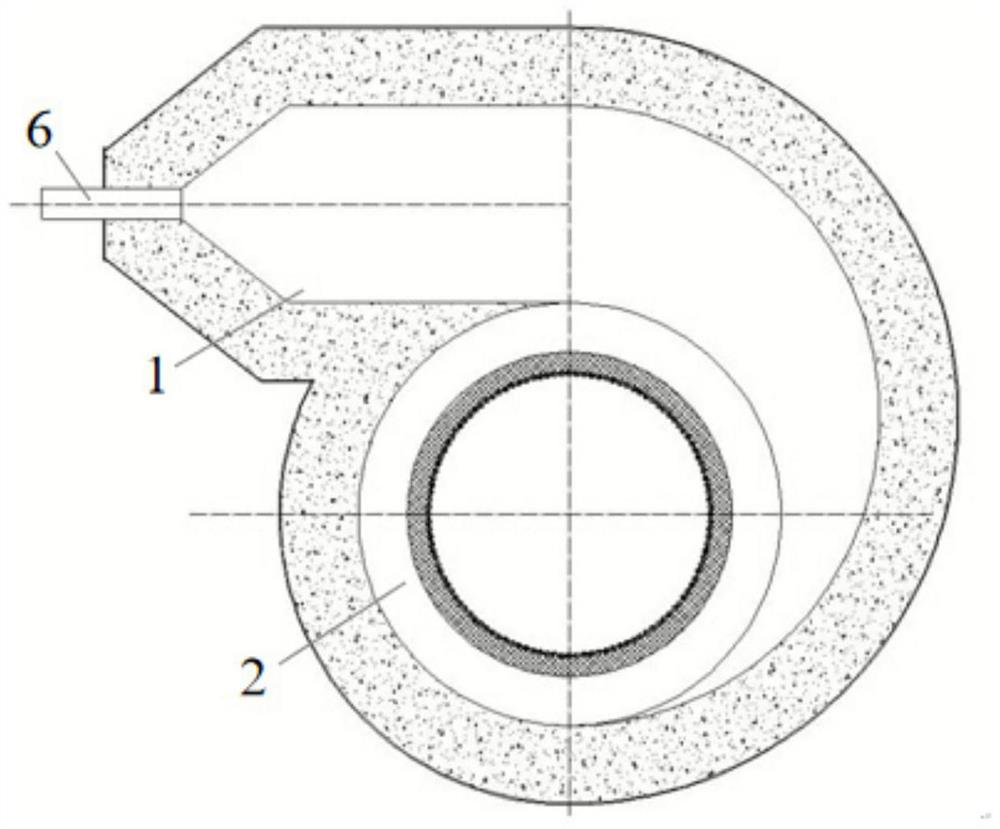

[0050] like figure 1 , figure 2 As shown, a glass melter-gasifier in this embodiment includes a shell 7, the bottom of the shell 7 is provided with a slag pool 5, the top is provided with a gas outlet 9, and the cavity of the shell 7 is provided with a slag pool 5. There is a gasification reaction chamber and a gas slag separation section 4. The gasification reaction chamber includes a main gasification reaction section 1, a swirl reaction section 2, and a chill section 3, which are arranged in sequence from top to bottom. The end face of the section 1 is provided with a burner channel 6 , and the main gasification reaction section 1 is connected downward to the swirl reaction section 2 in a spirally tapered manner. The gasification furnace in this embodiment adopts a spiral gasification reaction chamber, which can realize efficient shunting of gas slag. During the swirling process of liquid slag, it will flow down against the wall under the action of centrifugal force, and ...

Embodiment 2

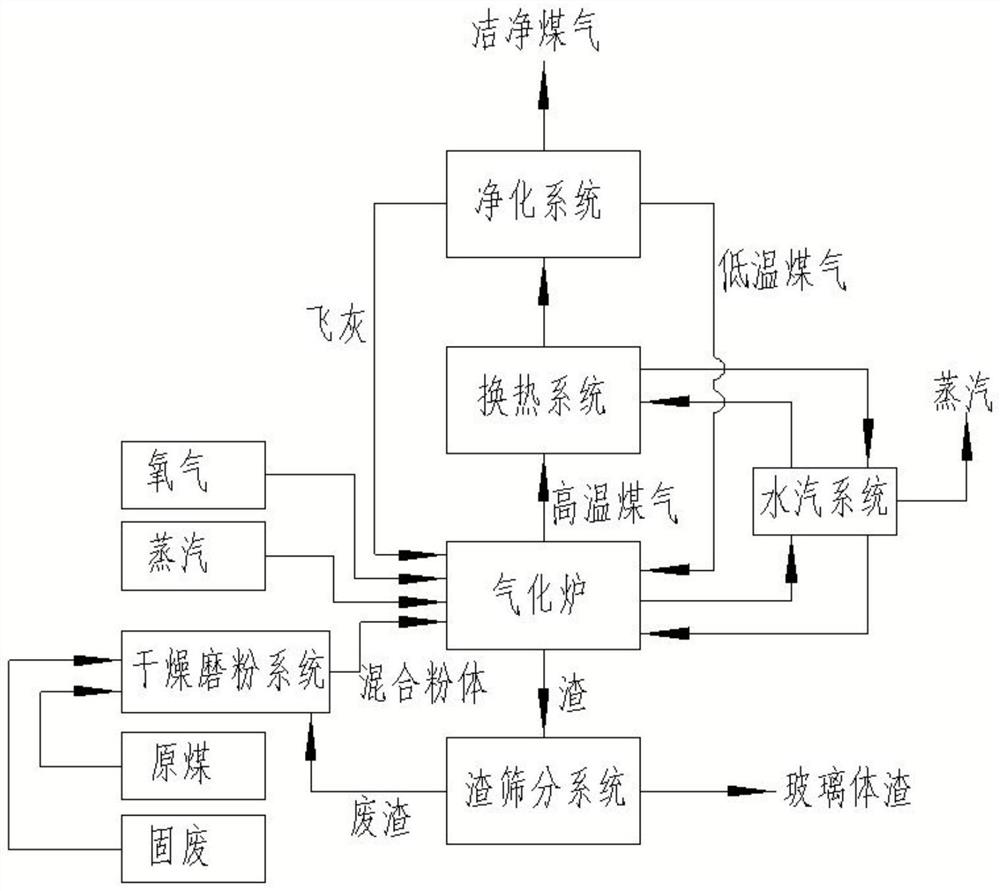

[0055] A glass body melting and gasification system in this embodiment includes a drying and grinding system, a slag screening system, a heat exchange system, a purification system, a water vapor system, and the above-mentioned gasifier. The output channel of the drying and grinding system is connected to Gasifier, the slag output end of the gasifier is connected to the slag screening system, and the slag screening system is connected to the drying and grinding system; the gas output end of the gasifier is connected to the heat exchange system and the purification system in turn; the gasifier and the water vapor system form Circulation passage, the water vapor system and the heat exchange system form a circulation passage. Among them, the function of the dry grinding system is to grind the raw materials with large particle size into small particle size powder that meets the requirements of gasification, and dry the moisture in the process; the gasifier is the main equipment for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com