Quartz sand tailing mud recycling method

A technology of quartz sand and tailings, which is applied in the direction of recycling technology, mechanical material recovery, chemical instruments and methods, etc., can solve the problems of large environmental hazards, HF has high toxicity, etc., and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

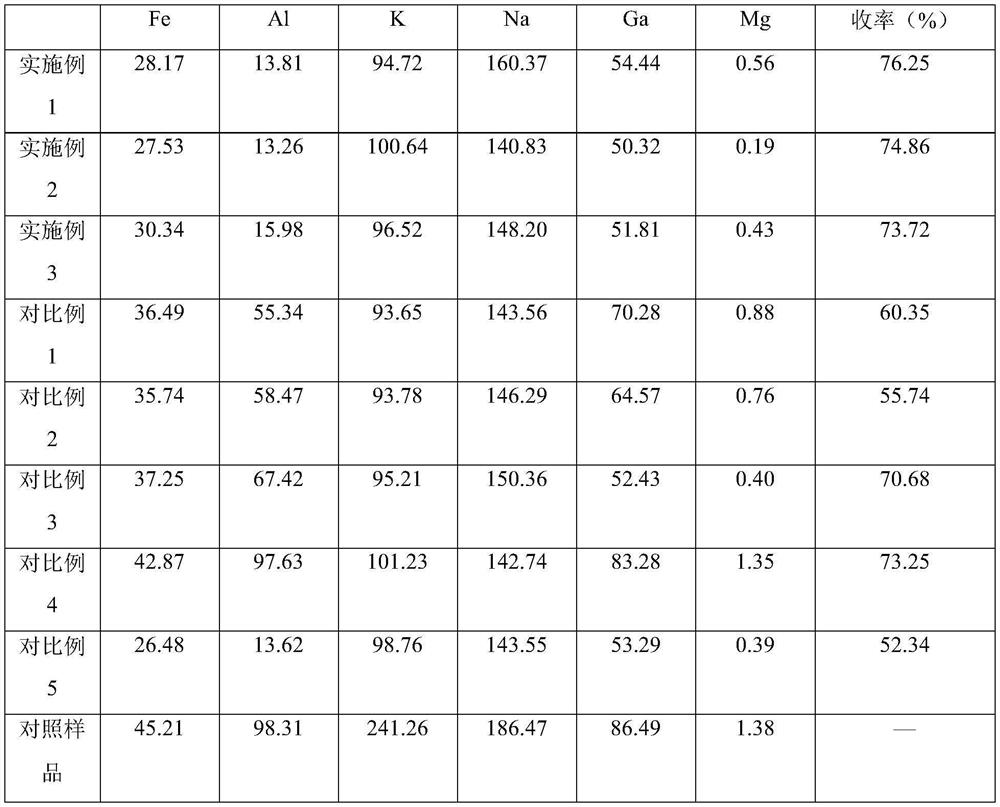

Embodiment 1

[0028] A method for recycling quartz sand tailings, comprising the following steps:

[0029] (1) Washing: the quartz sand tailing mud is washed with water;

[0030] (2) Magnetic separation: magnetic separation of the washed quartz sand tailings to remove magnetic metal impurities and strong magnetic ores;

[0031] (3) Classification: classify the quartz sand tailings after magnetic separation to obtain 150-300 mesh ultra-fine-grained quartz sand tailings, 80-150 mesh fine-grained quartz sand tailings, and 20-80 mesh coarse-grained quartz sand tailings;

[0032] (4) low-temperature pulverization: after the fine-grained and coarse-grained quartz sand tailings are pulverized at a low temperature at a temperature of -65 ° C, and mixed with the ultra-fine-grained quartz sand tailings obtained in step (3) into ultra-fine powder;

[0033] (5) Flotation: After the cationic collector tetraethylamine chloride aqueous solution is prepared, the inhibitor is added, and the pH is adjusted ...

Embodiment 2

[0038] A method for recycling quartz sand tailings, comprising the following steps:

[0039] (1) Washing: the quartz sand tailing mud is washed with water;

[0040] (2) Magnetic separation: magnetic separation of the washed quartz sand tailings to remove magnetic metal impurities and strong magnetic ores;

[0041] (3) Classification: classify the quartz sand tailings after magnetic separation to obtain 150-300 mesh ultra-fine-grained quartz sand tailings, 80-150 mesh fine-grained quartz sand tailings, and 20-80 mesh coarse-grained quartz sand tailings;

[0042] (4) low-temperature pulverization: after the fine-grained and coarse-grained quartz sand tailings are pulverized at a low temperature at a temperature of -10 ° C, and mixed with the ultra-fine-grained quartz sand tailings obtained in step (3) into ultra-fine powder;

[0043] (5) Flotation: After the cationic collector tetraethylamine chloride aqueous solution is prepared, the inhibitor is added, and the pH is adjusted ...

Embodiment 3

[0048] A method for recycling quartz sand tailings, comprising the following steps:

[0049] (1) Washing: the quartz sand tailing mud is washed with water;

[0050] (2) Magnetic separation: magnetic separation of the washed quartz sand tailings to remove magnetic metal impurities and strong magnetic ores;

[0051] (3) Classification: classify the quartz sand tailings after magnetic separation to obtain 150-300 mesh ultra-fine-grained quartz sand tailings, 80-150 mesh fine-grained quartz sand tailings, and 20-80 mesh coarse-grained quartz sand tailings;

[0052] (4) low-temperature pulverization: after the fine-grained and coarse-grained quartz sand tailings are pulverized at a low temperature at a temperature of 0 ° C, and mixed with the ultra-fine-grained quartz sand tailings obtained in step (3) into ultra-fine powder;

[0053] (5) Flotation: After the cationic collector tetraethylamine chloride aqueous solution is added, the inhibitor is added, and the pH is adjusted to 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com