Industrial waste salt resourceful treatment method

A technology for industrial waste salt and treatment methods, which is applied in the direction of chemical instruments and methods, solid waste removal, energy input, etc., can solve the problems of large amount of industrial waste salt, waste of resources, occupying large landfill resources, etc., and achieve product quality Excellent, reduced energy consumption, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

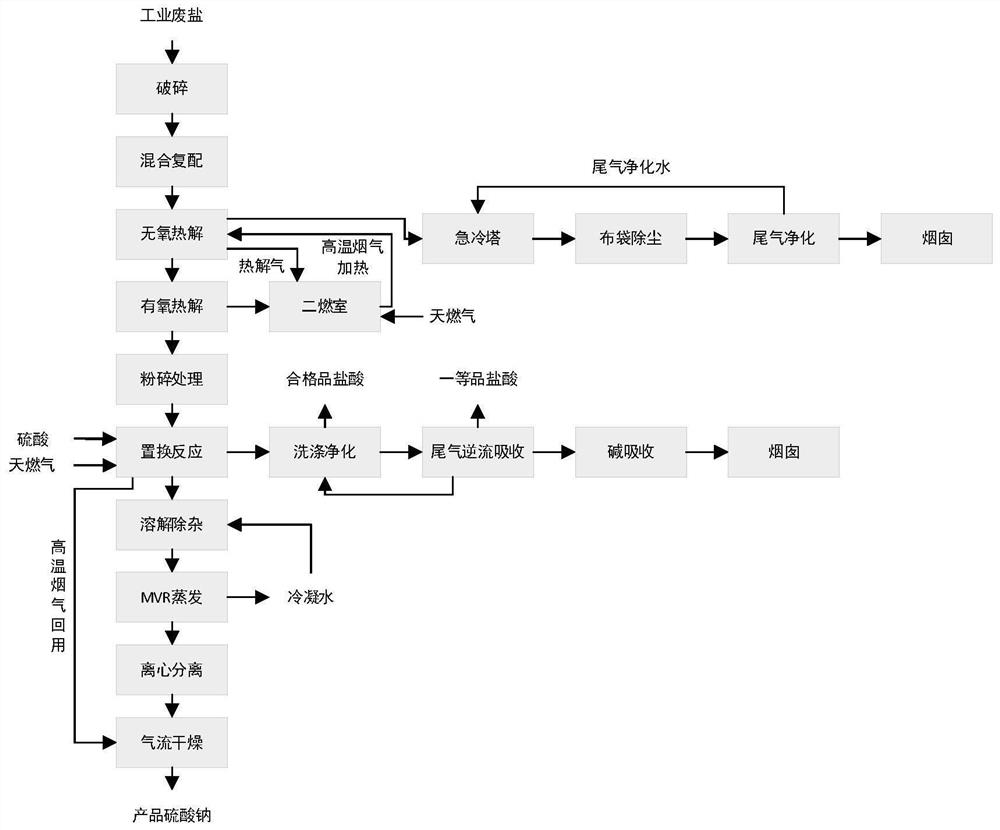

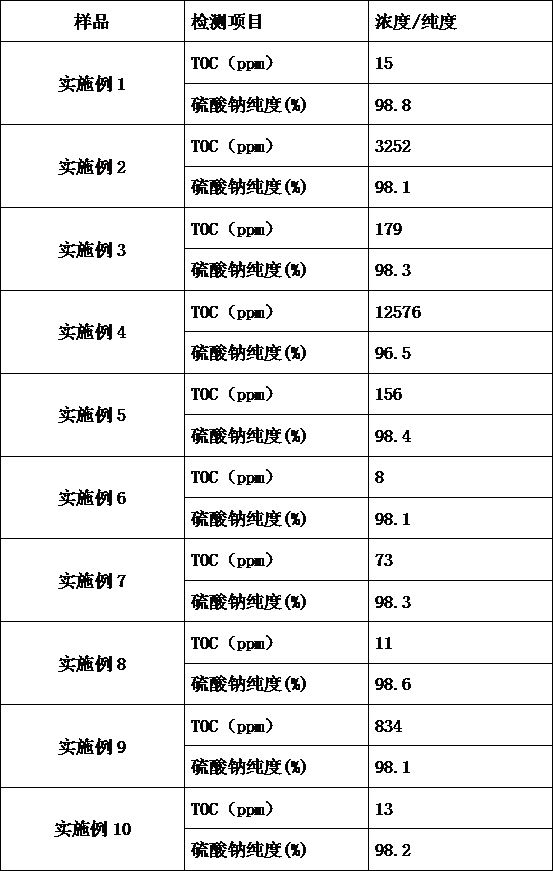

[0027] like figure 1 As shown in the figure, an industrial waste salt resource treatment method, the industrial waste salt is sequentially subjected to crushing, mixing and compounding, anaerobic pyrolysis, aerobic pyrolysis, high-temperature crushing, replacement reaction, dissolution and impurity removal, MVR Evaporation, centrifugal separation and air drying, and finally sodium sulfate crystals are obtained; anaerobic pyrolysis adopts rotary kiln baking or spiral tube baking heating method, the pyrolysis time is 60 minutes, and the pyrolysis temperature is 500 °C; aerobic pyrolysis A chain plate reactor is used, the upper part of the chain plate of the chain plate reactor is attached with ceramic fiber cloth, and the lower part has a heating device, the aerobic pyrolysis time is 40 minutes, the pyrolysis temperature is 600 ℃, and the TOC of waste salt after aerobic pyrolysis is 600ppm Below, the TOC of the waste salt after anaerobic pyrolysis is 3000 ppm or less, the TOC of...

Embodiment 2

[0033] Compared with Example 1, other steps remain unchanged, anaerobic pyrolysis and related steps are omitted, and the obtained sodium sulfate crystal purity and TOC concentration are detected.

Embodiment 3

[0035] Compared with Example 1, other steps remain unchanged, aerobic pyrolysis and related steps are omitted, and the obtained sodium sulfate crystal purity and TOC concentration are detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com