Microemulsion for soil remediation, preparation method of microemulsion and remediation method of petroleum-contaminated soil

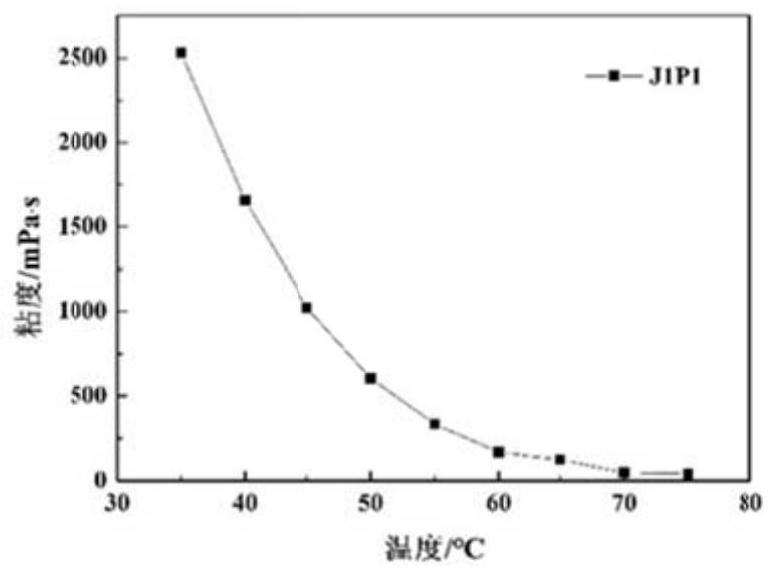

A technology for soil remediation and oil pollution, applied in the field of oil-contaminated soil remediation, can solve the problems of large amount of elution agent, poor elution efficiency, large residue, etc., and achieves simple and easy remediation method, high elution efficiency, and reduced viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

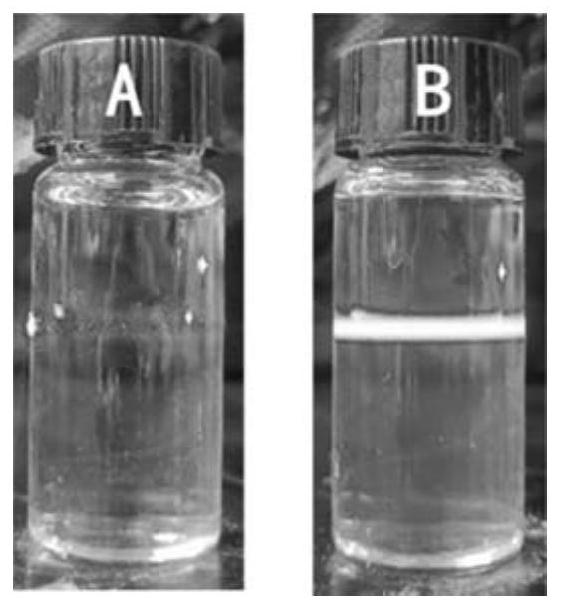

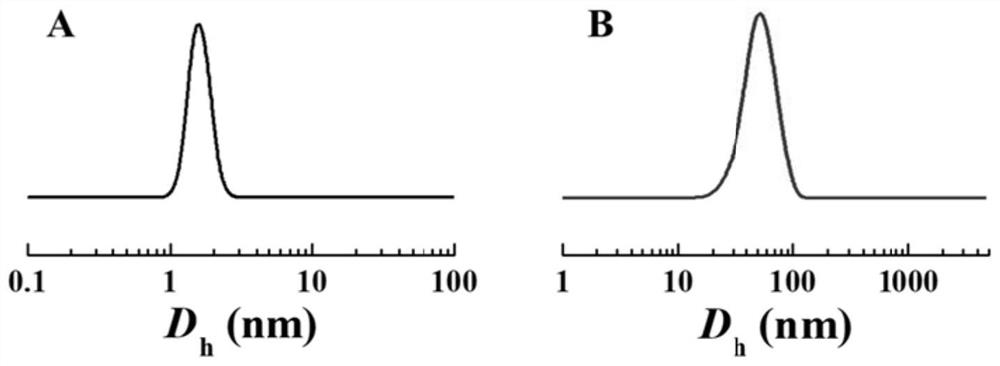

[0044]Get the sulfonate of 20g polyoxyethylene ether, the petroleum sulfonate of 20g and the water of 46.5g mix homogeneously, then it is mixed homogeneously with 10g methylcyclohexane, 1g alkyl naphthalene and 2.5g isopropanol, in After stirring at a speed of 400 rpm at room temperature, a transparent microemulsion was obtained.

[0045] The above-mentioned 15g microemulsion was mixed with 3g of oil-contaminated soil samples (oil content 8.2wt%, calculated as total petroleum hydrocarbons) in Shengli Oilfield, and after stirring for 0.5h at 50°C and 200 rpm, solid-liquid separation was carried out. Sample, the oil content of the separated soil sample is determined to be 1.9wt%, and the oil removal rate of the contaminated soil sample reaches 76.8%.

Embodiment 2

[0047] Get the phosphate of 25g polyoxyethylene oxypropylene ether, the lignosulfonate of 15g and the water of 46.5g mix evenly, then it is mixed with 10g methylcyclohexane, 1.5g polymethacrylate and 3g n-butanol Mix evenly, and obtain a transparent microemulsion after stirring at a speed of 400 rpm at room temperature.

[0048] The above-mentioned 9g microemulsion was mixed with 3g of oil-contaminated soil sample (oil content 8.2wt%, calculated as total petroleum hydrocarbons) in Shengli Oilfield, and after stirring for 0.5h at 50°C and 200 rpm, solid-liquid separation was carried out. Sample, the oil content of the separated soil sample is determined to be 2.2wt%, then its oil removal rate to the contaminated soil sample reaches 73.2%.

Embodiment 3

[0050] Get the sulfonate of 25g polyoxyethylene ether, the petroleum carboxylate of 20g and the water of 41.5g mix homogeneously, then it is mixed homogeneously with 10g cumene, 1g polymethacrylate and 2.5g isopropanol, in After stirring at a speed of 400 rpm at room temperature, a transparent microemulsion was obtained.

[0051] The above 21g microemulsion was mixed with 3g of the oil-contaminated soil sample (8.2wt% oil content, calculated as total petroleum hydrocarbons) at the Shengli Oilfield site, and after stirring for 0.5h at 70°C and 200 rpm, solid-liquid separation was carried out. Sample, the oil content of the separated soil sample is determined to be 1.5wt%, and then its oil removal rate to the polluted soil sample reaches 81.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com