PCB (Printed Circuit Board) base plate with hardening layer and preparation method and application of PCB base plate

A technology of hardening layer and backing plate, which is applied in the direction of wood layer products, chemical instruments and methods, coatings, etc. and warping, improve drilling quality, avoid the effect of draping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

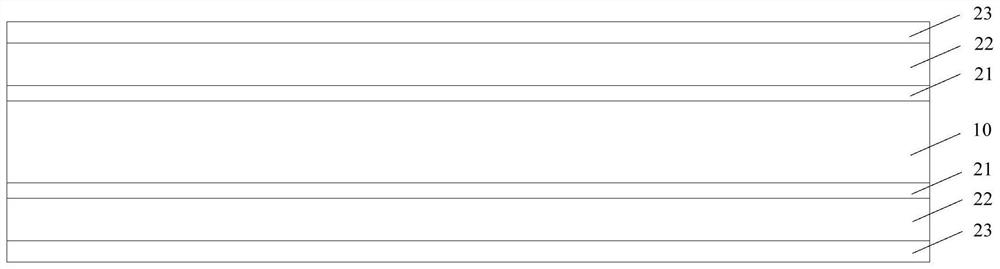

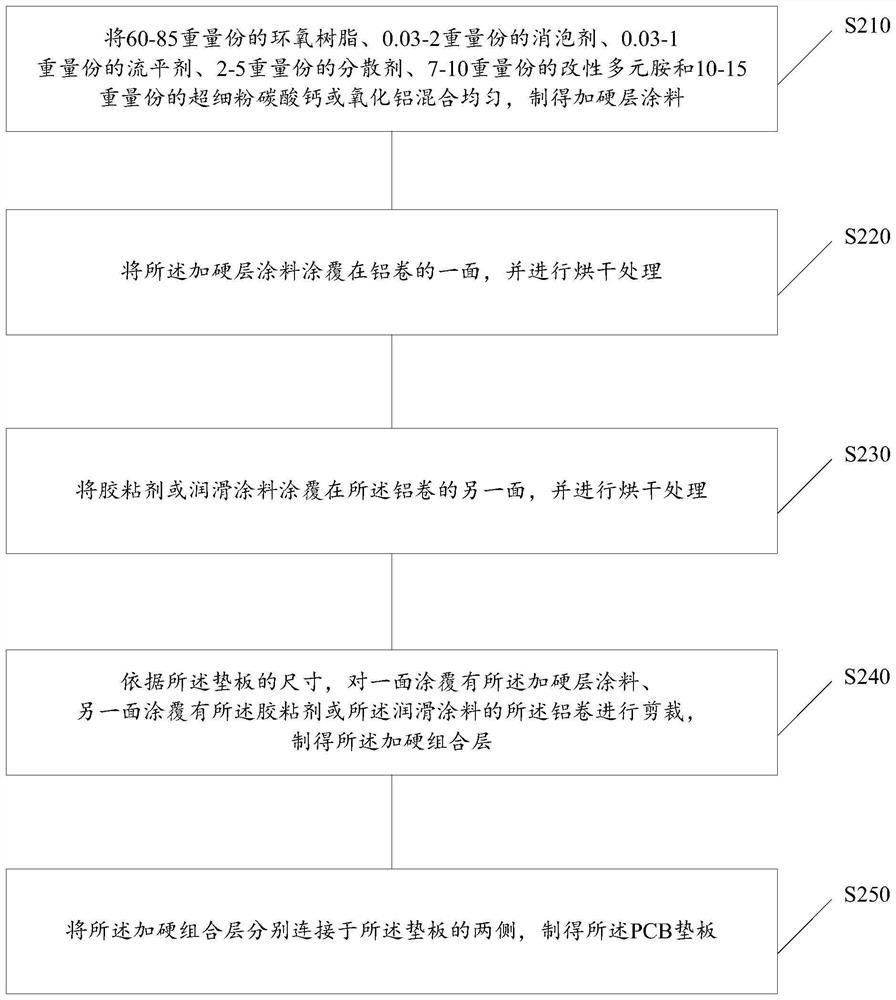

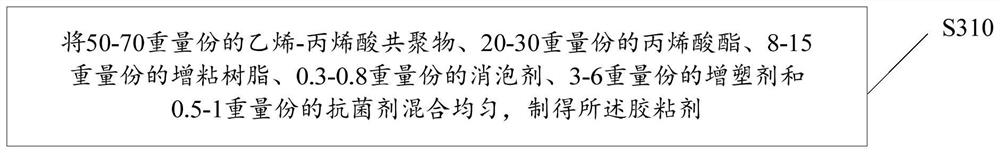

[0049] A PCB backing plate provided with a hardening layer, comprising: a backing plate 10 and a hardening combined layer arranged on both sides of the backing plate 10 oppositely; The adhesive layer 21, the aluminum foil 22 arranged on the surface of the adhesive layer 21, and the hardened layer 23 arranged on the surface of the aluminum foil 22; wherein, the material of the adhesive layer 21 is an adhesive or lubricating paint; The material of the hard layer 23 includes the following components in parts by weight: 60 parts of epoxy resin, 0.03 part of defoamer, 0.03 part of leveling agent, 2 parts of dispersant, 7 parts of modified polyamine, ultrafine powder calcium carbonate Or 10 parts of alumina.

Embodiment 2

[0051] A PCB backing plate provided with a hardening layer, comprising: a backing plate 10 and a hardening combined layer arranged on both sides of the backing plate 10 oppositely; The adhesive layer 21, the aluminum foil 22 arranged on the surface of the adhesive layer 21, and the hardened layer 23 arranged on the surface of the aluminum foil 22; wherein, the material of the adhesive layer 21 is an adhesive or lubricating paint; The material of the hard layer 23 includes the following components in parts by weight: 70 parts of epoxy resin, 1 part of defoamer, 0.5 part of leveling agent, 3 parts of dispersant, 8 parts of modified polyamine, and ultrafine powder calcium carbonate Or alumina 12 parts.

Embodiment 3

[0053] A PCB backing plate provided with a hardening layer, comprising: a backing plate 10 and a hardening combined layer arranged on both sides of the backing plate 10 oppositely; The adhesive layer 21, the aluminum foil 22 arranged on the surface of the adhesive layer 21, and the hardened layer 23 arranged on the surface of the aluminum foil 22; wherein, the material of the adhesive layer 21 is an adhesive or lubricating paint; The material of the hard layer 23 includes the following components in parts by weight: 85 parts of epoxy resin, 2 parts of defoaming agent, 1 part of leveling agent, 5 parts of dispersant, 10 parts of modified polyamine, ultrafine powder calcium carbonate Or 15 parts of alumina.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com