Method for preparing flame retardant magnesium hydroxide by taking industrial grade magnesium hydroxide as raw material

A magnesium hydroxide, industrial-grade technology, applied in the direction of magnesium hydroxide, chemical instruments and methods, magnesium compounds, etc., can solve the problems of wide particle size distribution of final products, high cost, and high particle size requirements of raw materials, so as to avoid environmental pollution And the effect of resource waste, low production cost, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

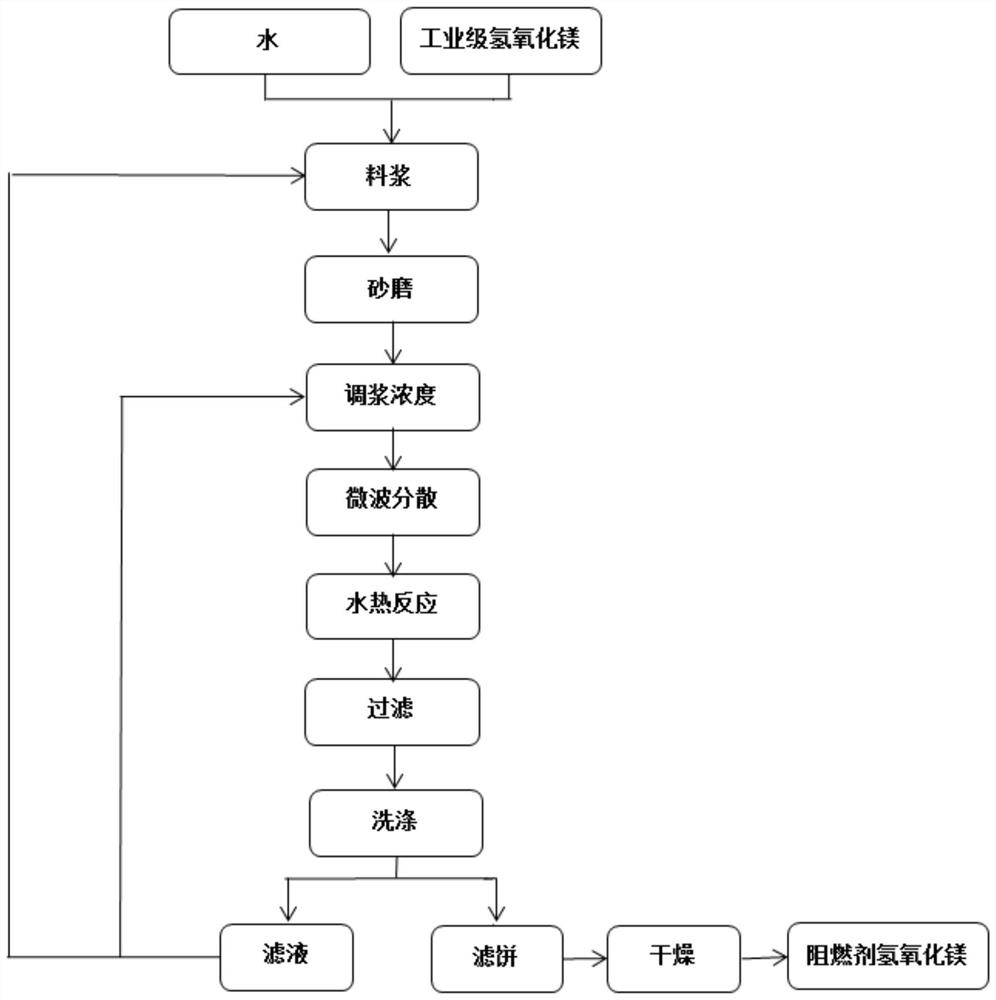

[0051] A method for preparing flame retardant magnesium hydroxide with technical grade magnesium hydroxide as raw material, comprising the following steps:

[0052](1) Weigh 100g of industrial-grade magnesium hydroxide and 300g of deionized water, add them to a sand mill and grind for 120min to obtain magnesium hydroxide slurry.

[0053] (2) The magnesium hydroxide slurry obtained in step (1) was diluted with water and dispersed in a microwave for 60 min.

[0054] (3) The magnesium hydroxide slurry after microwave dispersion in step (2) is transferred into the autoclave, the temperature of the autoclave is set to 140 ° C, the rotating speed is set to 400 r / min, and the timing is started when the set temperature is reached, After 6 h of reaction, the heating and stirring were turned off.

[0055] (4) After the autoclave is cooled to room temperature, it is filtered, the filter cake is washed with water, the filtrate is recycled in steps (1) and (2), and the filter residue is d...

Embodiment 2

[0057] A method for preparing flame retardant magnesium hydroxide with technical grade magnesium hydroxide as raw material, comprising the following steps

[0058] (1) Weigh 100g of industrial-grade magnesium hydroxide and 500g of deionized water, add them to a sand mill and grind for 120min to obtain magnesium hydroxide slurry.

[0059] (2) The magnesium hydroxide slurry obtained in step (1) was diluted with water and dispersed by ultrasonic for 60 min.

[0060] (3) The magnesium hydroxide slurry after ultrasonic dispersion in step (2) is transferred into the autoclave, the temperature of the autoclave is set to 140°C, the rotating speed is set to 400r / min, and the timing is started when the set temperature is reached, After 6 h of reaction, the heating and stirring were turned off.

[0061] (4) After the autoclave is cooled to room temperature, it is filtered, the filter cake is washed with water, the filtrate is recycled in steps (1) and (2), and the filter residue is drie...

Embodiment 3

[0063] A method for preparing flame retardant magnesium hydroxide with technical grade magnesium hydroxide as raw material, comprising the following steps

[0064] (1) Weigh 100g of industrial-grade magnesium hydroxide and 500g of deionized water, add them to a sand mill and grind for 120min to obtain magnesium hydroxide slurry.

[0065] (2) The magnesium hydroxide slurry obtained in step (1) was diluted with water and dispersed by ultrasonic for 60 min.

[0066] (3) The magnesium hydroxide slurry after ultrasonic dispersion in step (2) is transferred into the autoclave, the temperature of the autoclave is set to 160 ° C, the rotating speed is set to 400 r / min, and the timing is started when the set temperature is reached, After 8 h of reaction, heating and stirring were turned off.

[0067] (4) After the autoclave is cooled to room temperature, it is filtered, the filter cake is washed with water, the filtrate is recycled in steps (1) and (2), and the filter residue is dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com