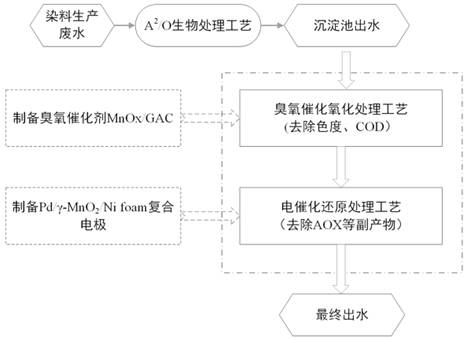

Dye wastewater treatment method by coupling ozone oxidation with electrocatalytic reduction

A technology of dye wastewater and ozone oxidation, which is applied in the direction of oxidized water/sewage treatment, energy wastewater treatment, water/sewage treatment, etc., can solve the problems of AOX by-products, AOX concentration rise, etc., and achieve stable water quality and mild reaction conditions , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Ozone oxidation coupled electrocatalytic reduction dye wastewater treatment method, comprising the following steps:

[0050] From a dye wastewater treatment plant in a chemical park, take 500 mL has passed A 2 Dye wastewater treated by the / O process, that is, primary treatment wastewater, the COD concentration in the primary treatment wastewater is 594 mg / L, the TOC concentration is 162 mg / L, and the AOX content is 8.1 mg / L, Cl - 、Br - Concentrations were 3380 mg / L and 165 mg / L, respectively, and the pH was 8.6.

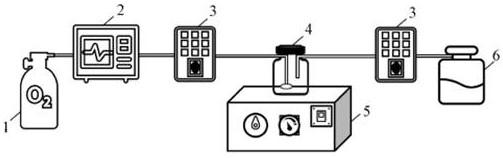

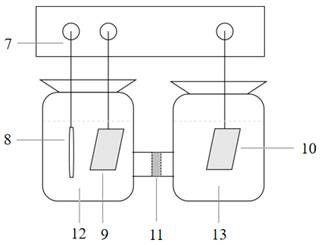

[0051] At room temperature, add 0.5 g / L MnO to the primary treatment wastewater x / GAC catalyst, and then through the 100 mesh sieve hole of the quartz aeration head to the primary treatment of wastewater into the ozone, ozone concentration of 40 mg / L, ozone flow of 0.5 L / min, treatment time of 1.5 h, to obtain secondary treatment of wastewater; with concentrated sulfuric acid to adjust the pH of secondary treatment of wastewater to 3.0; and then electrocatal...

Embodiment 2

[0053] Ozone oxidation coupled electrocatalytic reduction dye wastewater treatment method, comprising the following steps:

[0054] From a dye wastewater treatment plant in a chemical park, take 500 mL has passed A 2Dye wastewater treated by the / O process, that is, primary treatment wastewater, the COD concentration in the primary treatment wastewater is 594 mg / L, the TOC concentration is 162 mg / L, and the AOX content is 8.1 mg / L, Cl - 、Br - Concentrations were 3380 mg / L and 165 mg / L, respectively, and the pH was 8.6.

[0055] At room temperature, add 1.0 g / L MnO to the primary treatment wastewater x / GAC catalyst, and then through the 100 mesh sieve hole of the quartz aeration head to the primary treatment of wastewater into the ozone, ozone concentration of 40 mg / L, ozone flow of 0.5 L / min, treatment time of 1.5 h, to obtain secondary treatment of wastewater; with concentrated sulfuric acid to adjust the pH of secondary treatment of wastewater to 3.0; and then electrocataly...

Embodiment 3

[0057] Ozone oxidation coupled electrocatalytic reduction dye wastewater treatment method, comprising the following steps:

[0058] From a dye wastewater treatment plant in a chemical park, take 500 mL has passed A 2 Dye wastewater treated by the / O process, that is, primary treatment wastewater, the COD concentration in the primary treatment wastewater is 594 mg / L, the TOC concentration is 162 mg / L, and the AOX content is 8.1 mg / L, Cl - 、Br - Concentrations were 3380 mg / L and 165 mg / L, respectively, and the pH was 8.6.

[0059] At room temperature, 1.5 g / L MnO is added to the primary treatment wastewater x / GAC catalyst, and then through the 100 mesh sieve hole of the quartz aeration head to the primary treatment of wastewater into the ozone, ozone concentration of 40 mg / L, ozone flow of 0.5 L / min, treatment time of 1.5 h, to obtain secondary treatment of wastewater; with concentrated sulfuric acid to adjust the pH of secondary treatment of wastewater to 3.0; and then electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com