Preparation method of liquid propyl silicon resin blend for personal care

A blend, propyltrimethoxysilane technology, applied in skin care preparations, hair care, cosmetic preparations, etc., can solve problems such as environmental hazards, increase process production costs, corrode production equipment, etc., to avoid Pollution, good hand feel, anti-aging effect of skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

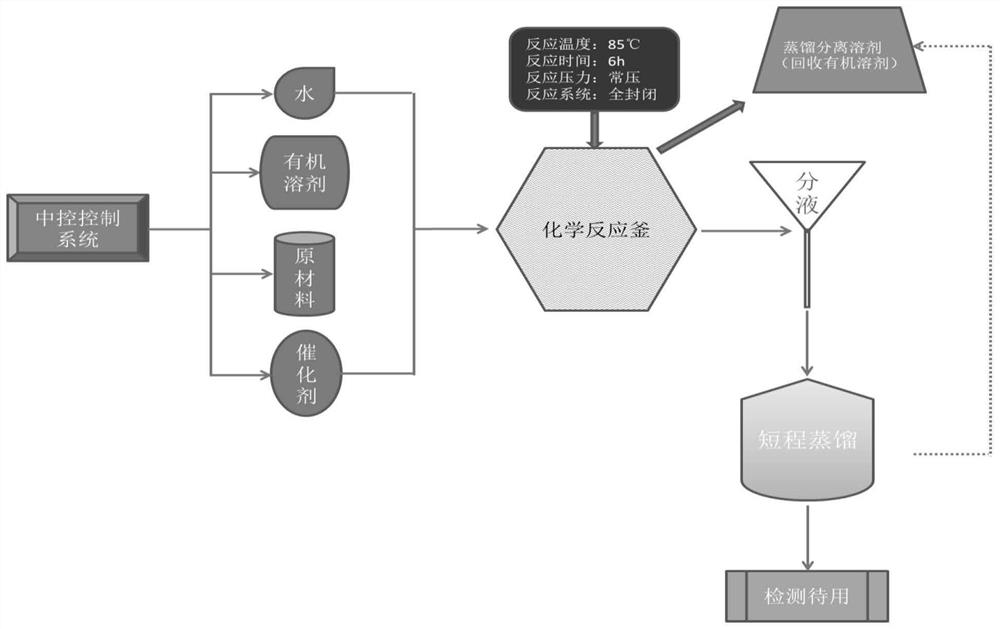

[0038] A preparation method of liquid propyl silicone resin blend for personal care, the steps are:

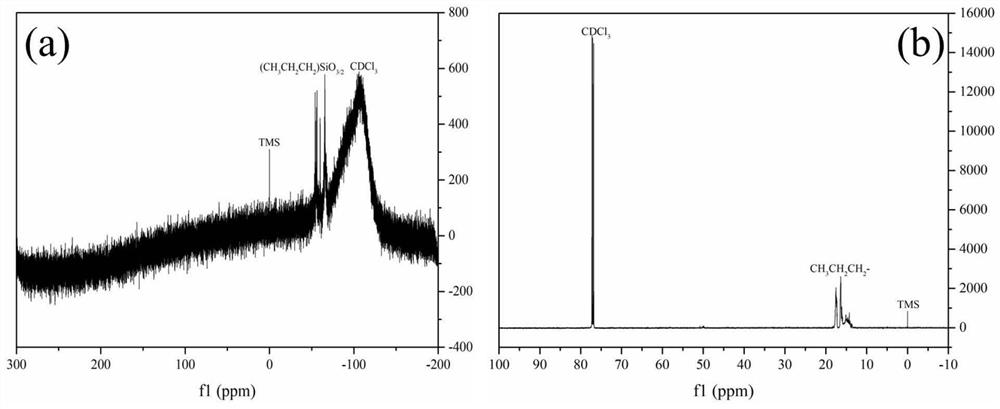

[0039] At room temperature, 11.66 mol of deionized water, 7.49 mol of cyclohexane, and 1.52 mol of dehydrated ethanol were added to a three-port reactor equipped with a thermometer, and the mechanical stirring was turned on, and the mixture was stirred until the mixture was evenly mixed; Add 4 mol of base silane into the container, continue to stir, then add 0.056 mol of trifluoromethanesulfonic acid dropwise, set the stirring speed to 280 rpm, turn on the circulating water, heat to 50 ° C, and react under this condition for 50 min; continue to heat up to 85 ° C, After the solvent is evaporated, the reaction is continued for 6 hours. After the reaction is completed, a large amount of deionized water is used to wash until the washing liquid is PH>5 (measured by a pH meter), and the liquid is separated. based silicone resin (≈360g). Its resin viscosity is 22000mPas (25°C), the ...

Embodiment 2

[0045] A preparation method of liquid propyl silicone resin blend for personal care, the steps are:

[0046] At room temperature, 11.66 mol of deionized water, 7.49 mol of toluene, and 1.52 mol of dehydrated ethanol were added to a three-port reactor equipped with a thermometer, and the mechanical stirring was turned on, and the mixture was stirred until the mixture was evenly mixed; 4 mol of propyltrimethoxysilane was added. Add it to the container, continue stirring, then dropwise add 0.064 mol of trifluoromethanesulfonic acid, set the stirring speed to 280 rpm, turn on the circulating water, heat it to 50 ° C, and react under this condition for 50 min; continue to heat up to 85 ° C, wait to be steamed out After the solvent, the reaction was continued for 6 hours. After the reaction, a large amount of deionized water was used to wash until the pH of the washing solution was > 5 (measured by a pH meter), the liquid was separated, and the propyl silicone resin was obtained by s...

Embodiment 3

[0050] A preparation method of liquid propyl silicone resin blend for personal care, the steps are:

[0051] At room temperature, 11.66 mol of deionized water, 3.745 mol of cyclohexane, 3.745 mol of toluene, and 1.52 mol of absolute ethanol were added to a three-port reactor equipped with a thermometer, mechanical stirring was turned on, and the mixture was stirred uniformly; Add 4 mol of trimethoxysilane to the container, continue to stir, then add 0.08 mol of trifluoromethanesulfonic acid dropwise, set the stirring speed to 280 rpm, turn on the circulating water, heat to 50 ° C, and react under this condition for 50 min; continue to heat up to 85°C, continue to react for 6h after the solvent is evaporated, wash with a large amount of deionized water after the reaction is completed until the pH of the washing solution>5 (measured by a pH meter), separate liquids, and perform short-path distillation (120~160°C, 9~20Pa) , to obtain propyl silicone resin (≈385g). Its resin visc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com