Lamination structure of lithium ion battery, preparation of lamination structure, battery cell, preparation of battery cell and application of battery cell

A technology of lithium-ion battery and laminated structure, which is applied in the manufacture of electrolyte batteries, equipment for manufacturing primary batteries, primary batteries, etc. It can solve the problems of low yield rate of batteries, low production efficiency of batteries, and high folding frequency. Productivity and the effect of shortening lamination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method of a lithium ion battery laminated structure, comprising the following steps:

[0029] (1) cutting the composite pole piece band A consisting of the positive pole piece, the negative pole piece and the separator to obtain a single composite pole piece unit A;

[0030] (2) cutting the composite pole piece band B composed of the positive pole piece, the negative pole piece and the separator to obtain a single composite pole piece unit B;

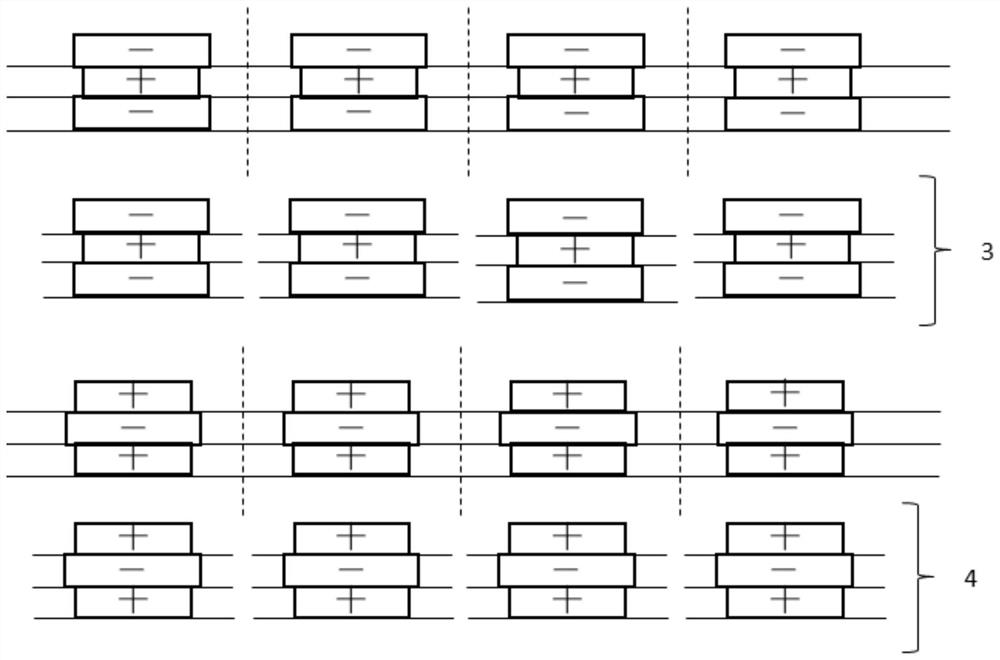

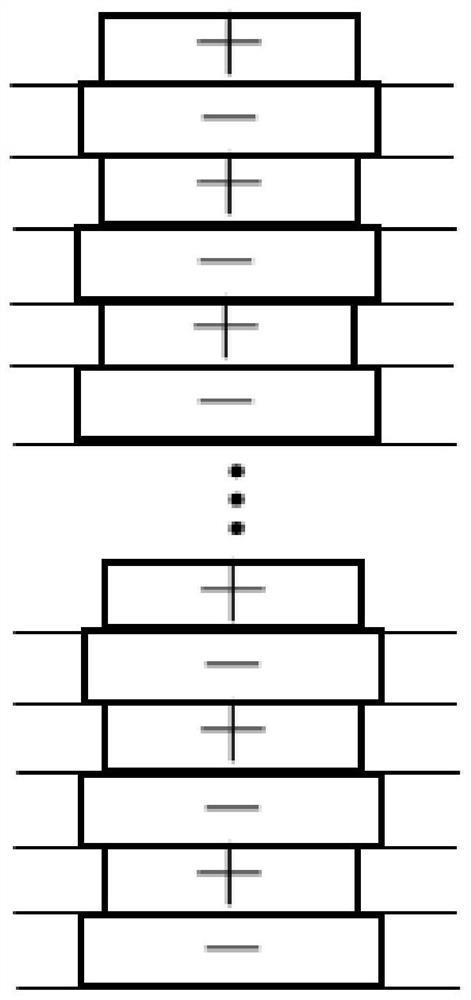

[0031] (3) place the single composite pole piece unit B obtained in step (2) on the upper layer of the single composite pole piece unit A obtained in step (1), and repeat the stacking several times to obtain the composite pole piece unit C;

[0032] (4) A layer of separator is placed on the uppermost positive electrode of the composite electrode C, and then a negative electrode is placed to obtain a lithium ion battery laminated structure.

[0033] In an embodiment of the present invention, i...

Embodiment 1

[0045] This embodiment provides a battery cell of a lithium ion battery.

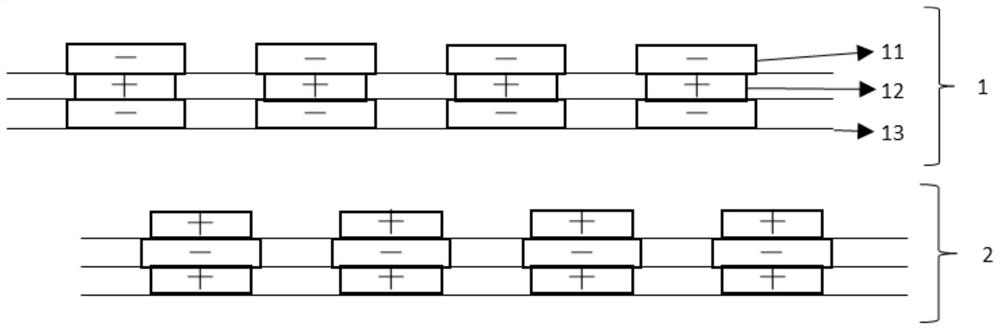

[0046] like Figure 1-5 As shown, the composite pole piece belt A1 is composed of a layer of positive pole pieces 12, two layers of negative pole pieces 11 and three layers of parallel isolation films 13, and a layer of equidistant negative pole pieces 11 is placed on the bottommost isolation film 13, After that, a layer of separator 13 is placed on the negative pole piece 11, and then a layer of positive pole pieces 12 with equal spacing is placed on the layer of separator 13. The positive pole piece 12 is aligned with the center of the lower negative pole piece 13, and then the A layer of separator 13 is placed on the positive pole piece 12 , and a layer of equally spaced negative pole pieces 11 is placed on the layer of separator 13 , and the negative pole piece 11 is aligned with the center of the lower positive pole piece 12 .

[0047] The composite pole piece belt B2 is composed of one layer of n...

Embodiment 2

[0054] This embodiment provides a lithium-ion battery, including the above-mentioned battery cell.

[0055] On the basis of the lithium ion battery cells prepared in Example 1, welding tabs, top sealing, side sealing operations, liquid injection and pre-sealing were performed, and finally the operations of standing still for aging, hot and cold pressing, formation and secondary sealing were performed, Get a lithium-ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap