Laminated structure and semiconductor device

A structure and semiconductor technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems that are still in progress, and achieve excellent heat dissipation, good film thickness distribution, and large area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

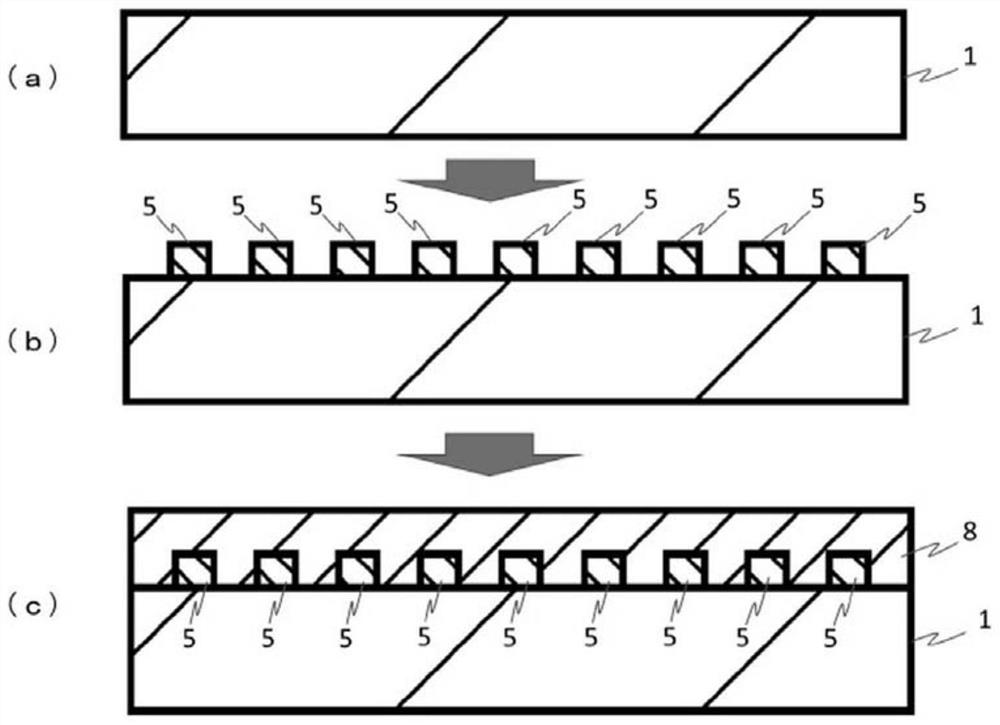

[0151] Embodiments of the present invention will be described below using the accompanying drawings, but the present invention is not limited thereto.

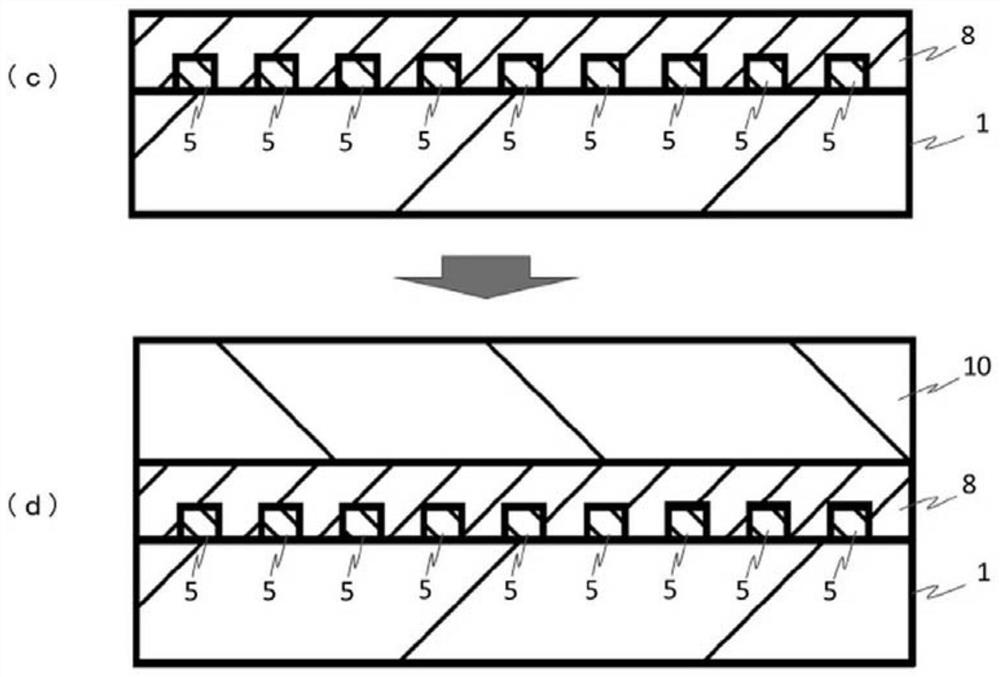

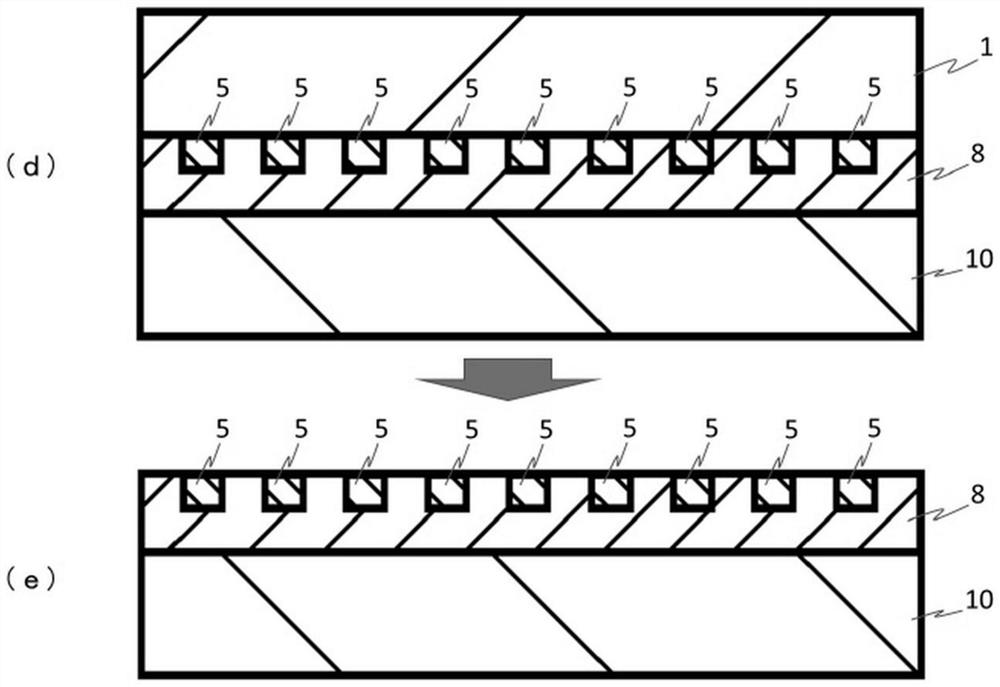

[0152] The laminated structure can be obtained by a method in which a crystal growth layer is formed on a substrate for crystal growth by crystal growth including lateral crystal growth, and a support having a thermal conductivity of 100 W / m·k or more at room temperature is attached to the substrate. On the crystal growth layer, the substrate for crystal growth is subsequently peeled off, whereby the laminated structure can be obtained.

[0153] (Example)

[0154] 1. Fabrication of laminated structure

[0155] As a substrate for crystal growth, an ELO mask is formed on the surface. In addition, a sapphire substrate was used as a substrate for crystal growth. In the present invention, as the sapphire substrate, a sapphire substrate having an r-plane or an S-plane as a main surface is preferably used. figure 1 (a) shows the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com