Preparation method and application of solid nano calcium carbonate denitration agent with high fluidity, high efficiency and low by-products

A technology of nano-calcium carbonate and high fluidity, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. The effect of clogging inside the pipe and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

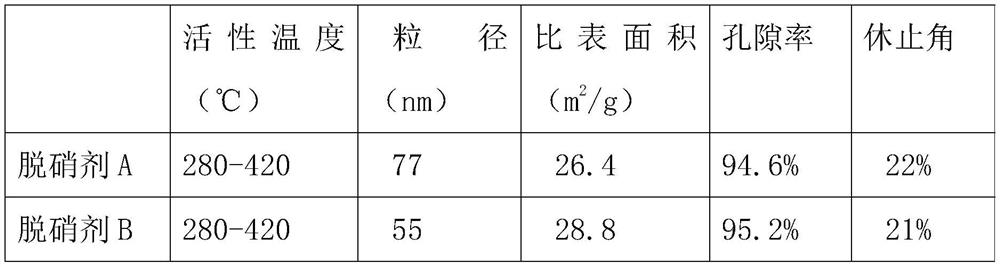

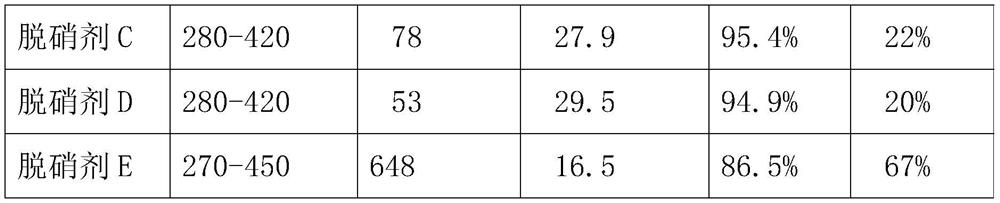

Examples

Embodiment 1

[0022] A preparation method of a solid-state high fluidity, high efficiency, and low by-product nano-calcium carbonate denitration agent, comprising the following steps:

[0023] S1: after adding 500g of water in the saponification kettle, the temperature is raised, and after the temperature is raised to 60 °C, 150g of 1,2-hydroxystearic acid is put into the saponification kettle, and it is fully stirred to form a hyperdispersant slurry;

[0024] S2: Dissolve 400 g of nano-calcium carbonate in absolute ethanol to form a 3.4 mol / L nano-calcium carbonate solution;

[0025] S3: drop the nano calcium carbonate solution that S2 obtains into the reactor, and in the reactor, add the hyperdispersant slurry that S1 obtains, the polystyrene of 150g, the trimethyl borate of 20g and the stearic acid of 50g, at 1400r Stir 20min under the rotating speed of / min to obtain the first product;

[0026] S4: the first product is placed on the surface of the filter press for filter press, and dur...

Embodiment 2

[0029] A preparation method of a solid-state high fluidity, high efficiency, and low by-product nano-calcium carbonate denitration agent, comprising the following steps:

[0030] S1: put 500g of water in the saponification kettle and heat up, after warming up to 60°C, put 200g of 1,2-hydroxystearic acid into the saponification kettle, and fully stir it to form a hyperdispersant slurry;

[0031] S2: Dissolve 400 g of nano-calcium carbonate in absolute ethanol to form a 3.4 mol / L nano-calcium carbonate solution;

[0032] S3: drop the nano calcium carbonate solution that S2 obtains into the reactor, and add the hyperdispersant slurry that S1 obtains, the polystyrene of 160g, the trimethyl borate of 20g and the stearic acid of 50g in the reactor, at 1400r Stir 30min under the rotating speed of / min to obtain the first product;

[0033] S4: put the first product on the surface of the filter press for filter press, and during the filter press, it is washed with pure water to obtain...

Embodiment 3

[0036] A preparation method of a solid-state high fluidity, high efficiency, and low by-product nano-calcium carbonate denitration agent, comprising the following steps:

[0037] S1: after putting in 500g of water in the saponification kettle, heat up, after being warming up to 60 ℃, drop into the 200g dioctyl phthalate in the saponification kettle, fully stir to make it form a hyperdispersant slurry;

[0038] S2: Dissolve 600 g of nano-calcium carbonate in absolute ethanol to form a 4.8 mol / L nano-calcium carbonate solution;

[0039] S3: drop the nano calcium carbonate solution that S2 obtains into the reactor, and in the reactor, add the hyperdispersant slurry that S1 obtains, the polystyrene of 150g, the trimethyl borate of 20g and the stearic acid of 50g, at 1400r Stir 25min under the rotating speed of / min, obtain the first product;

[0040] S4: the first product is placed on the surface of the filter press for filter press, and during the filter press, it is washed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com