Patents

Literature

35results about How to "Small angle of repose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

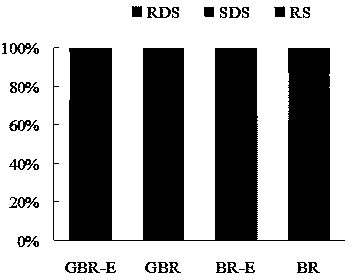

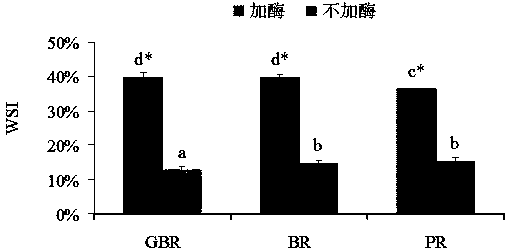

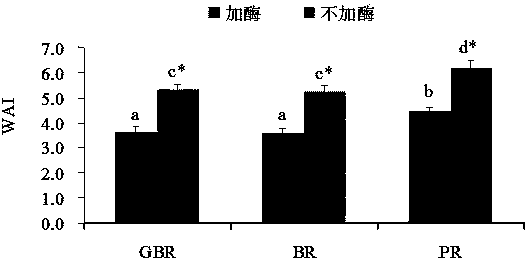

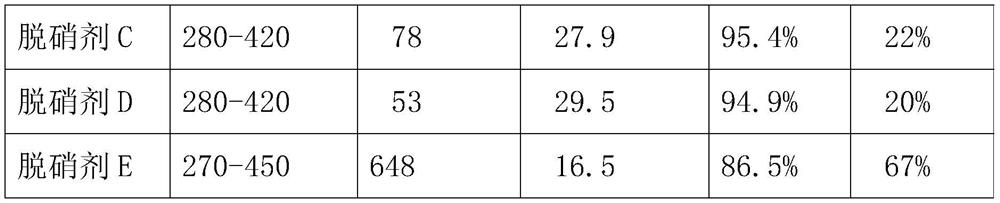

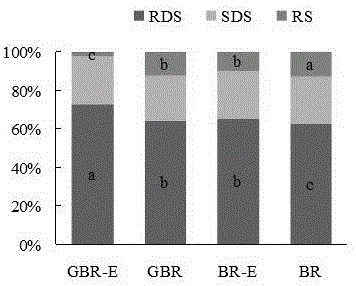

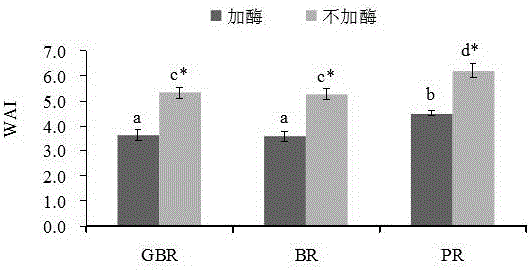

Processing method for improving digestibility and reconstituability of instant brown rice powder

The invention discloses a processing method for improving digestibility and reconstituability of instant brown rice powder. The processing method comprises the following steps: (1) germinating rice and then removing rich husk so as to obtain germinated brown rice; (2) crushing the germinated brown rice, sieving the crushed germinated brown rice with a 60-mesh sieve, sprinkling a high-temperature alpha-amylase weak solution into obtained brown rice powder, adjusting moisture content to 10 to 20%, carrying out uniform mixing, then carrying out sealing with a sealing bag, placing the sealing bag in a refrigerator with a temperature of 4 DEG C and balancing moisture for 10 to 20 h, wherein the sprinkling amount of the alpha-amylase weak solution is 40 to 60 U / g, i.e., 40 to 60 U units of the alpha-amylase weak solution is sprinkled into each g of the brown rice powder; and (3) after moisture balancing, carrying out extrusion cooking and crushing so as to obtain the instant brown rice powder. According to the invention, through effective combination of germination, enzymatic hydrolysis with high-temperature alpha-amylase and extrusion cooking, digestibility and reconstituability of the instant brown rice powder are improved to a greatest extent.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

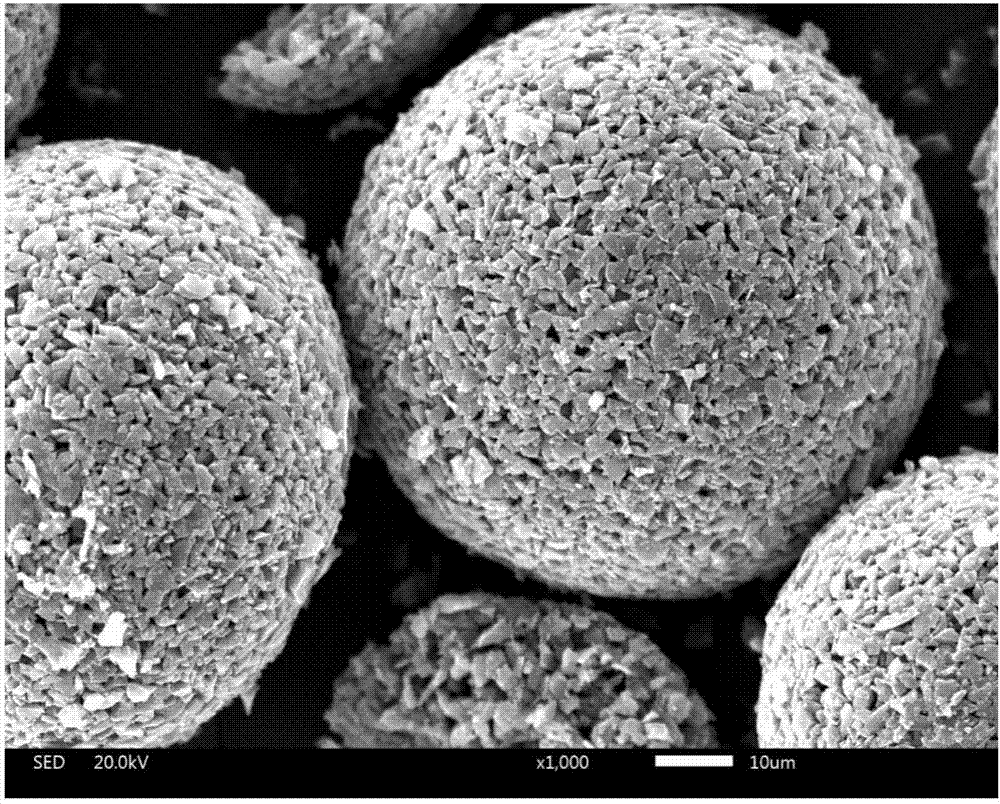

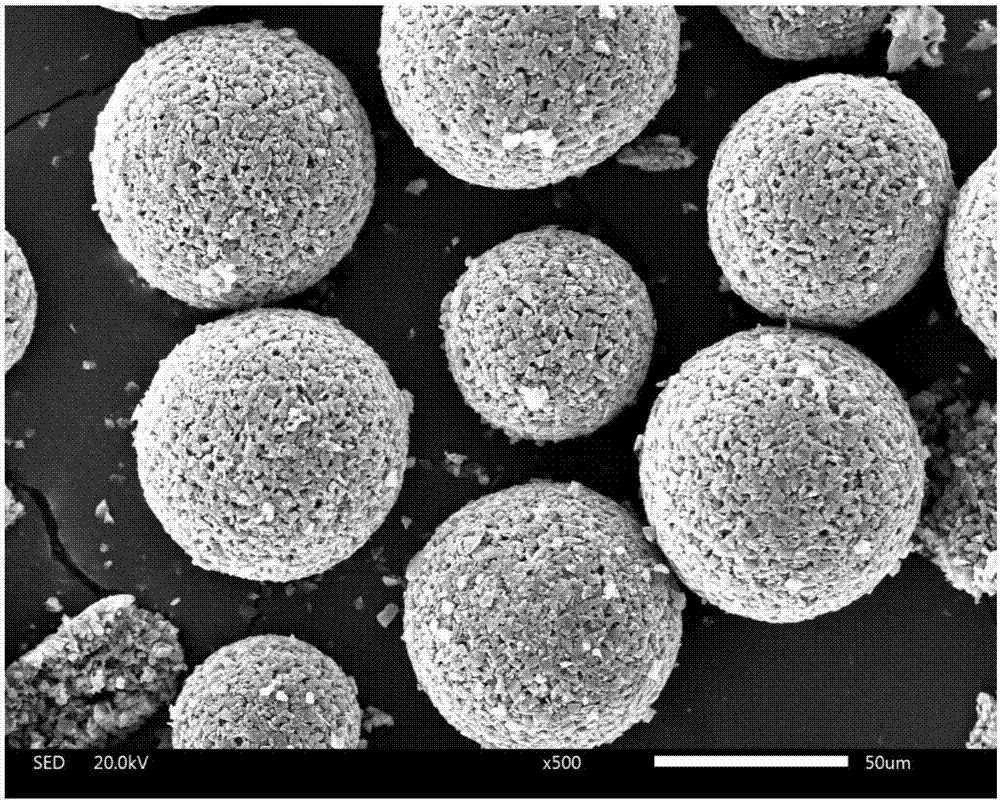

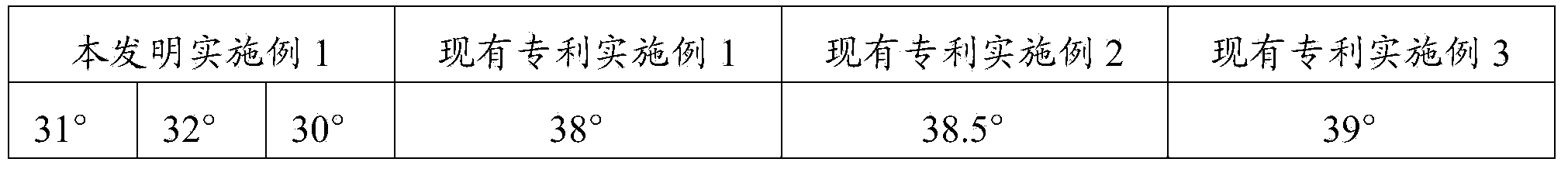

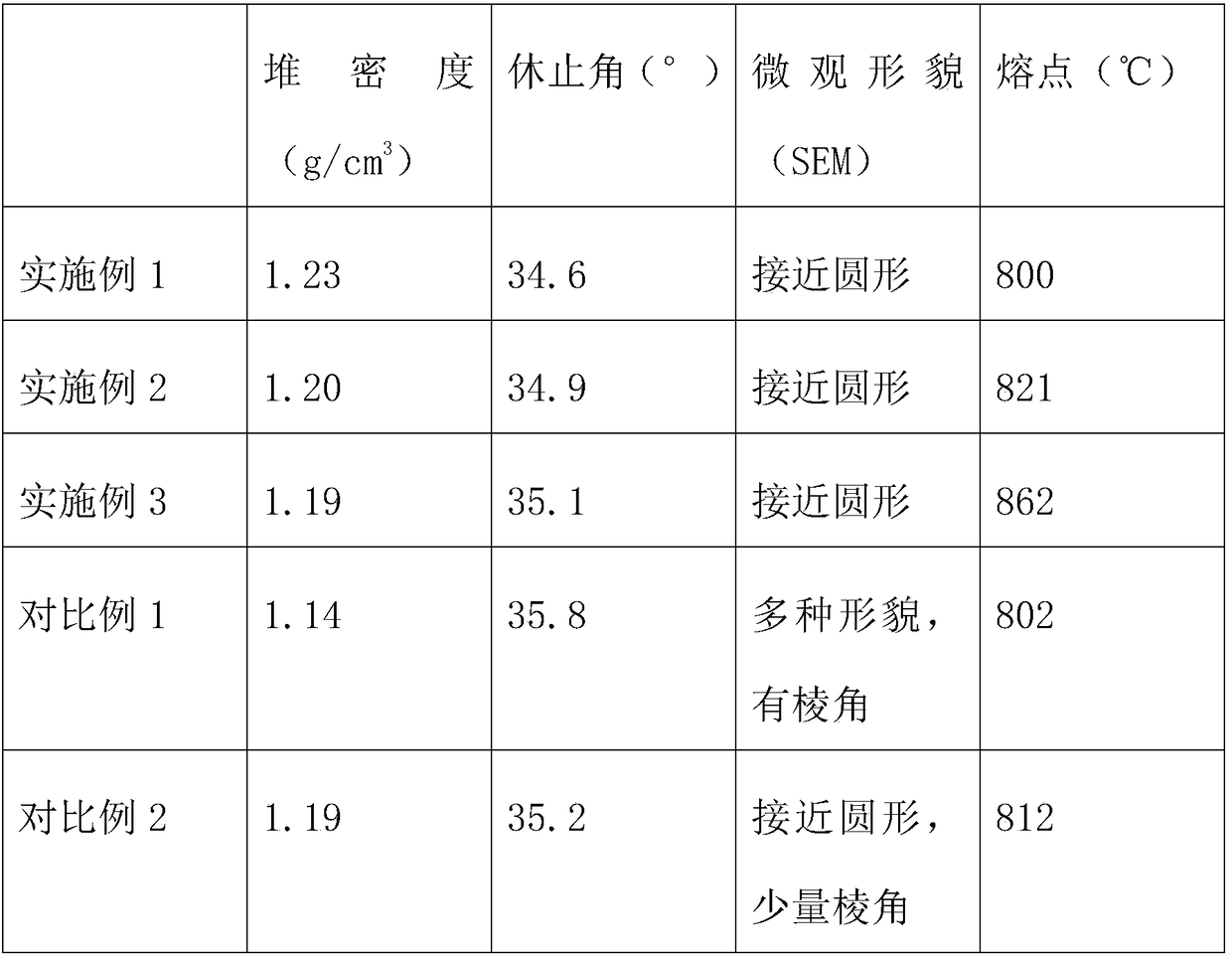

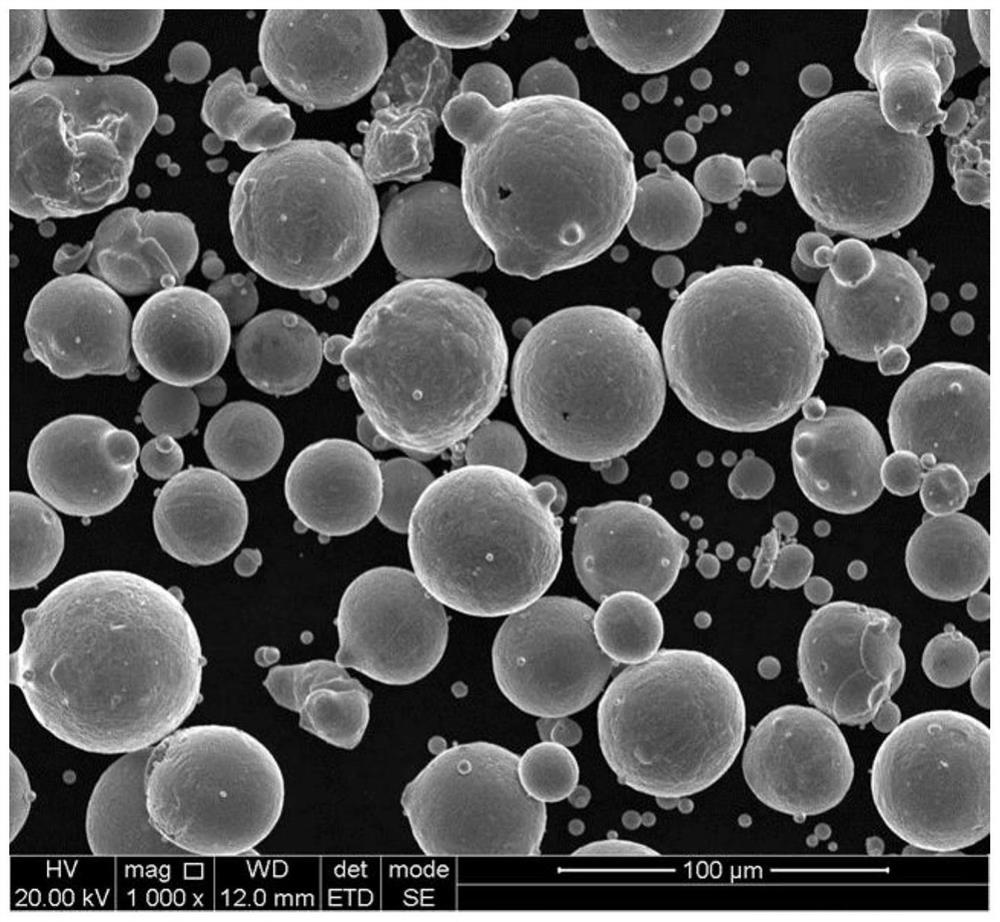

Method for preparing ultrafine boron carbide granulation powder by combining high-energy ball milling with spray drying technology

The invention relates to a method for preparing ultrafine boron carbide granulation powder by combining high-energy ball milling with a spray drying technology. The method comprises the following steps: firstly, burdening; secondly, preparing slurry: putting deionized water, a lubricant A, a lubricant B, a dispersing agent, a binder A and a binder B into a polytetrafluoroethylene ball mill tank, adding ball milling beads on a planetary ball mill to carry out ball milling mixing, then adding boron carbide micropowder into the ball mill tank and continuously carrying out ball milling for 0.5 hour, and then adding a binder C into the ball mill tank and carrying out ball milling for 12 to 18 hours; finally, adding a defoaming agent into the ball mill tank and carrying out ball milling for 10 minutes to obtain the slurry; thirdly, carrying out spray drying granulation: carrying out drying granulation on the slurry by using a spray drying granulator to obtain the ultrafine boron carbide granulation powder. According to the preparation method disclosed by the invention, the spherical granulation powder is obtained by combining wet high-energy ball milling with the spray granulation technology; the obtained powder is helpful to the forming of the boron carbide powder and the improvement on relative density of a biscuit.

Owner:WUHAN UNIV OF TECH

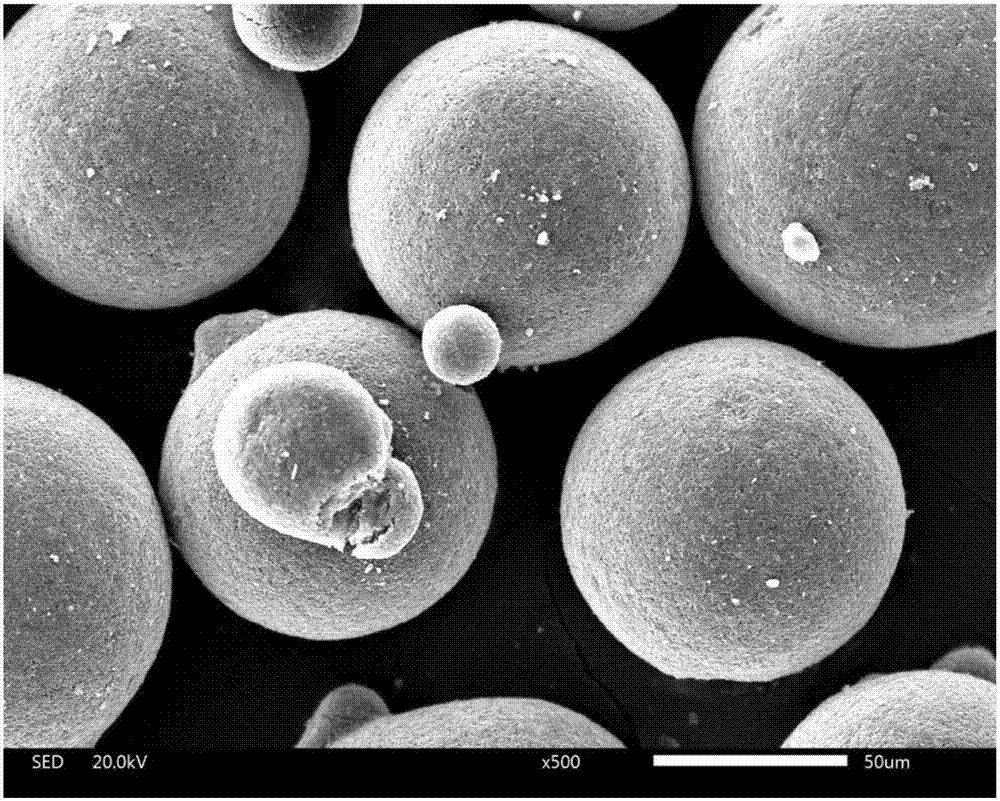

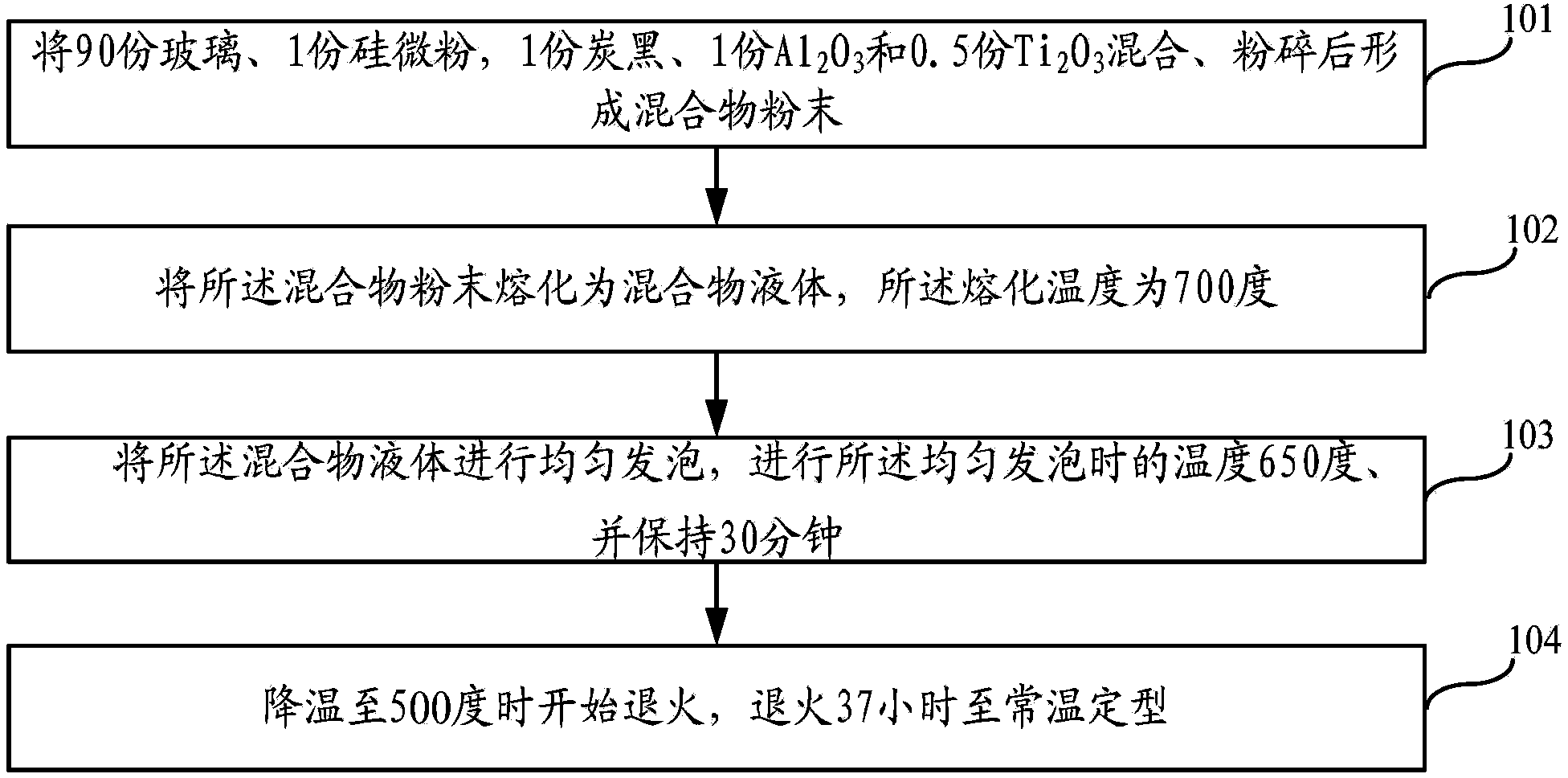

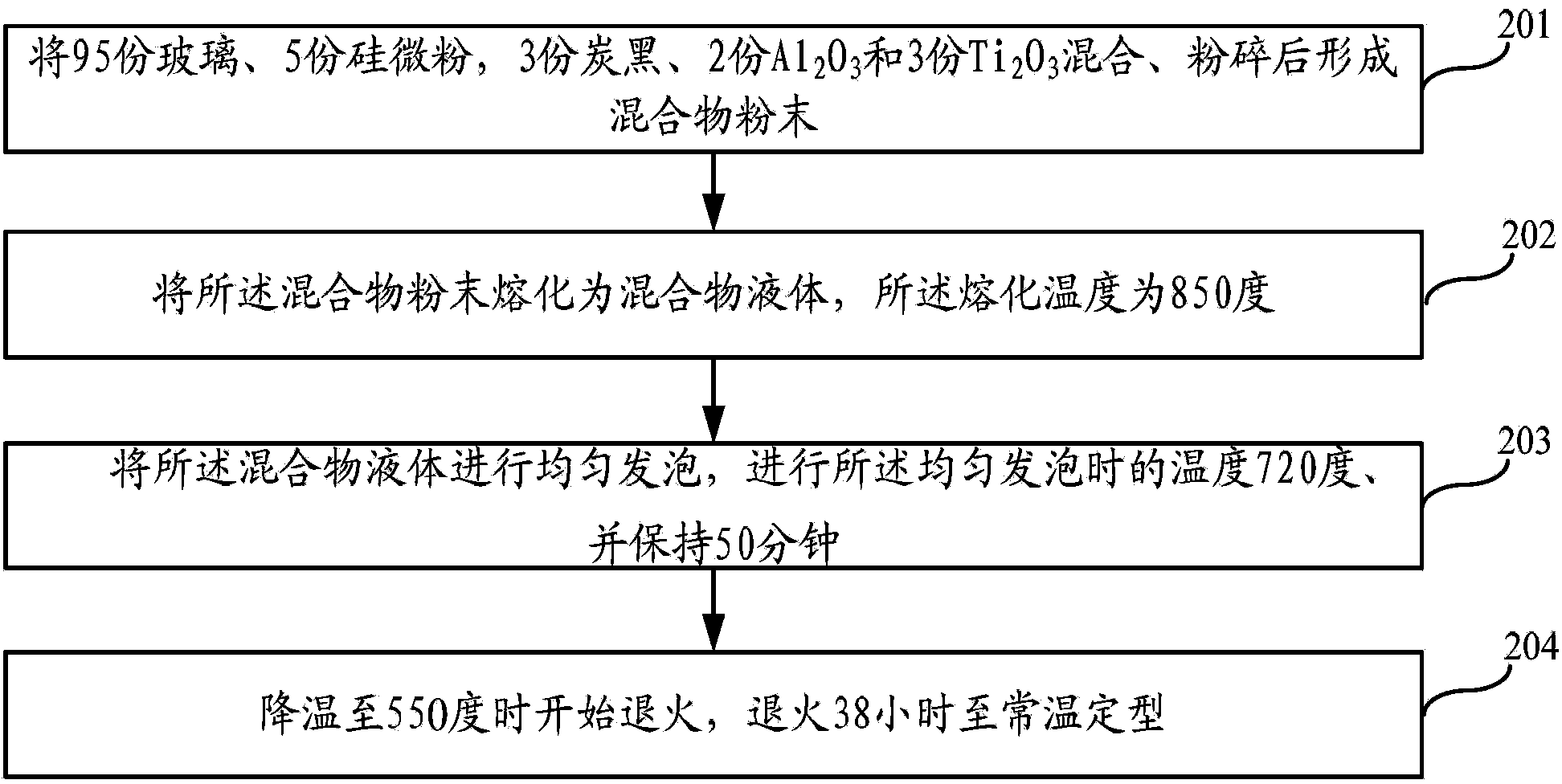

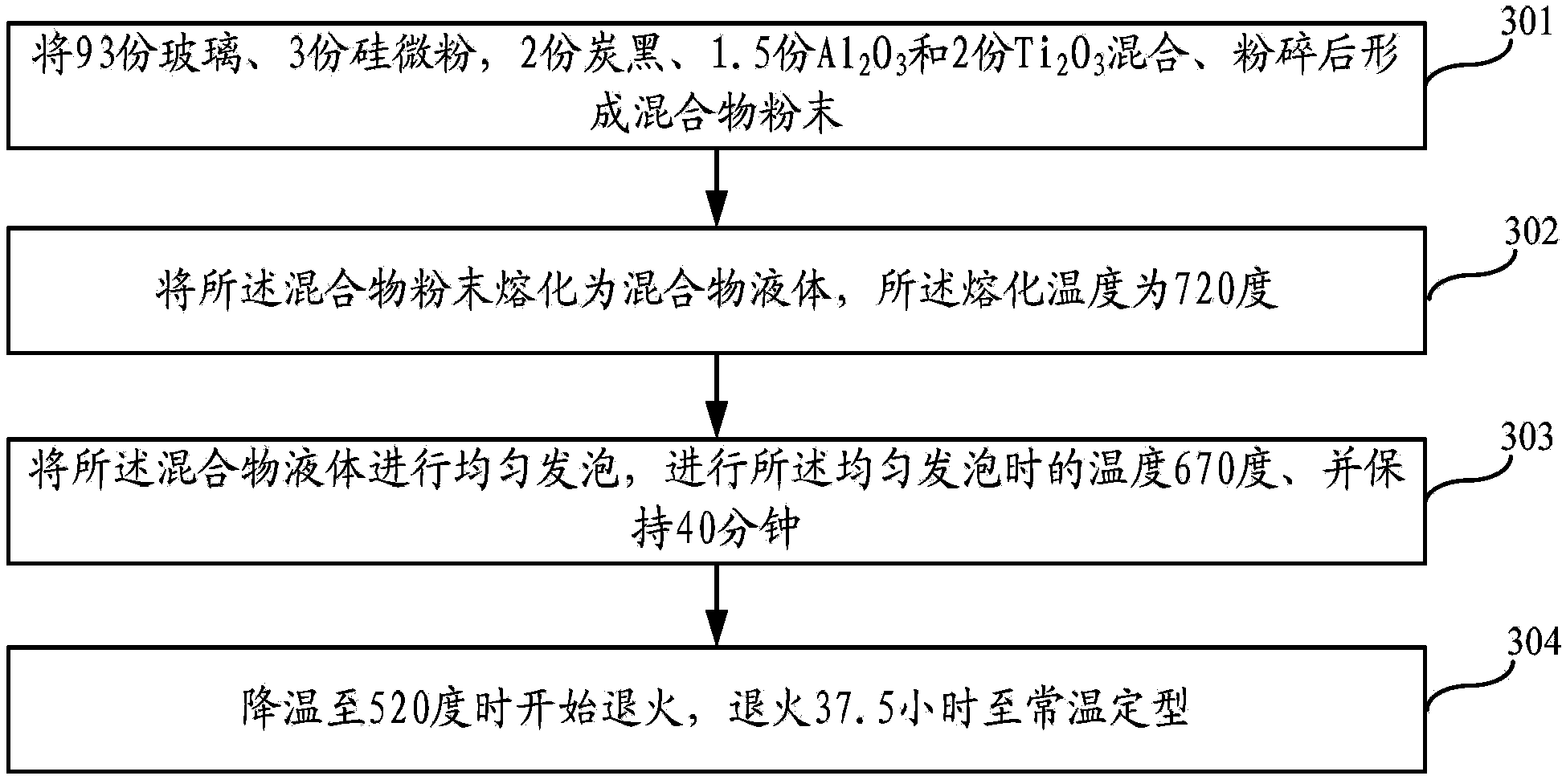

Foam glass and production method thereof

The invention relates to the field of industrial production, in particular to foam glass which has the advantages that the strength of the foam glass is improved and meanwhile the heat conductivity factor of the foam glass is reduced. The foam glass comprises the following components in parts by weight: 90-95 parts of glass, 1-5 parts of silicon micro-powder, 1-3 parts of foaming agent, 1-2 parts of modification additive and 0.5-3 parts of foaming accelerator. The production method of the foam glass comprises the following steps of: mixing and crushing 90-95 parts of glass, 1-5 parts of silicon micro-powder, 1-3 parts of foaming agent, 1-2 parts of modification additive and 0.5-3 parts of foaming accelerator to form mixture powder; melting the mixture powder into mixture liquid at the melting temperature of 700-850 DEG C; then uniformly foaming the mixture liquid at the temperature of 650-720 DEG C and keeping the uniform foaming for 30-50 minutes; starting to anneal when cooling to 500-550 DEG C after the uniform foaming is finished; and annealing for 37-38 hours to normal temperature for shaping.

Owner:BEIJING SHOUBANG NEW MATERIAL

High-liquidity starch and preparation method and application thereof

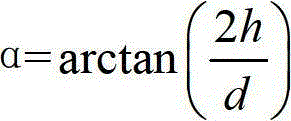

The invention discloses high-liquidity starch and a preparation method and the application thereof. The preparation process is simple, reaction is uniform, production cost is low, reaction time is short, expansion of starch particles under the alkaline reaction condition is restrained by sodium sulfate to avoid starch gelatinization and enable starch chemical modification to be centralized on the particle surfaces; introducing an ultrasonic field into the reaction process can improve reaction efficiency, reduce usage of chemical agents, shorten reaction time and reduce cost; electronegative substitute groups are crosslinked by metallic ions of different valences, a great amount of hydroxyls on the starch particle surfaces are shielded, and accordingly angle of repose of starch can be evidently decreased, and liquidity is improved. High-fluidity starch with the angle of repose ranging from 2 degrees to 5 degrees is obtained and has wide application values in industries of foods, daily chemicals, printing, agriculture, petroleum and the like.

Owner:SOUTH CHINA UNIV OF TECH

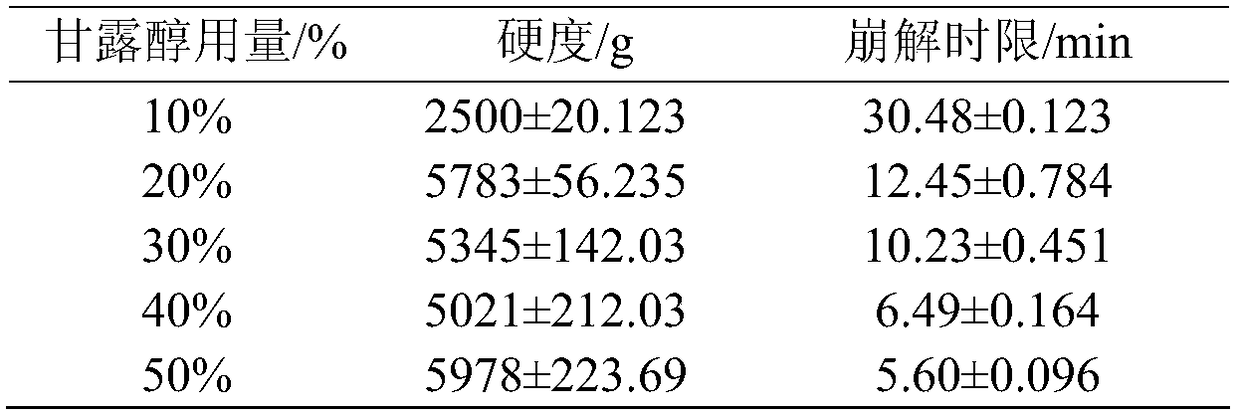

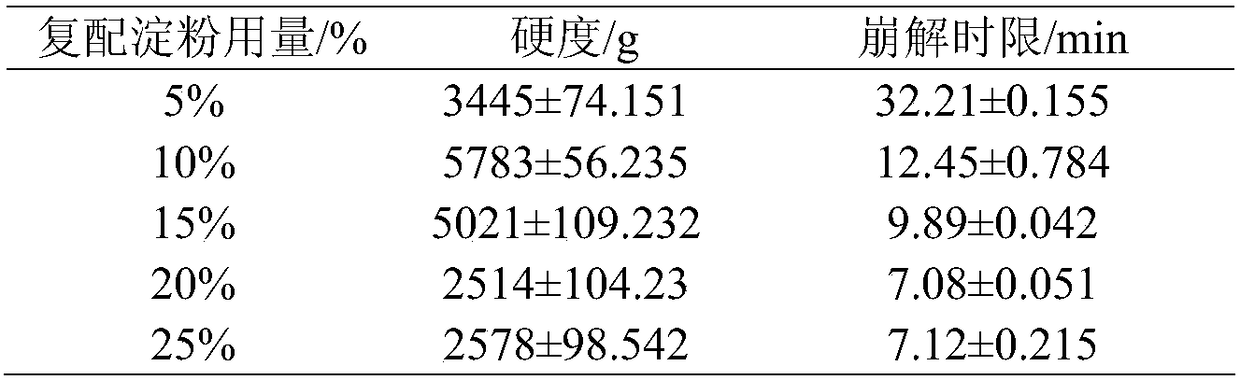

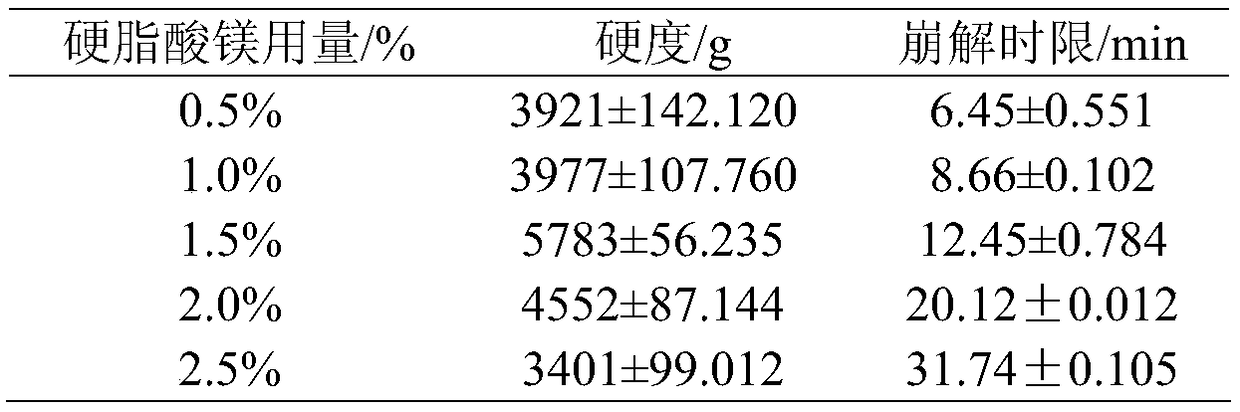

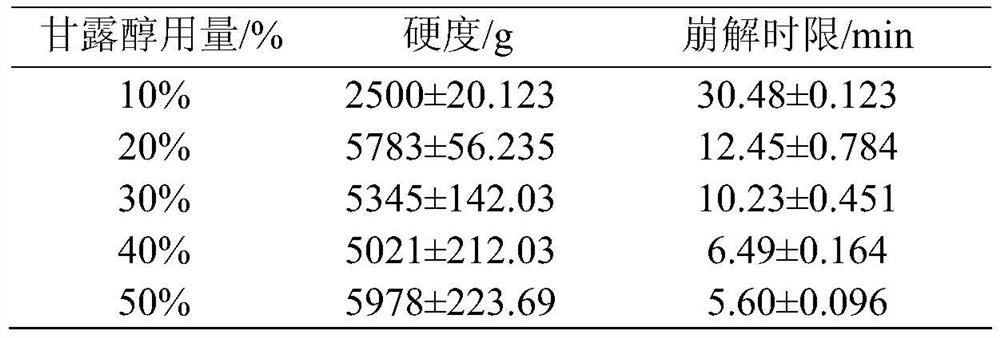

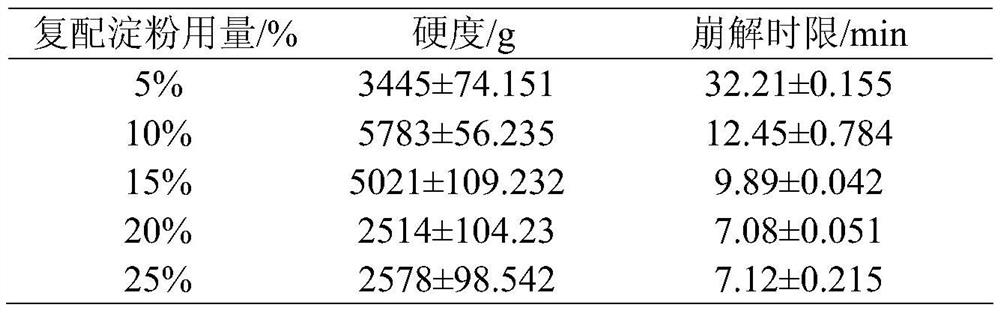

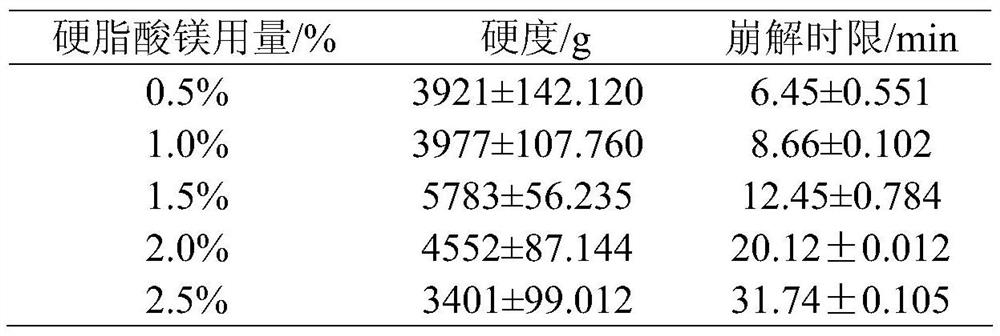

Preparation technology of green banana tablets

ActiveCN108783296AReduce browningImprove antioxidant capacityFood dryingFood ingredient functionsBanana powderMannitol

The invention discloses a preparation technology of green banana tablets. The preparation technology comprises the following steps of (1) preparing green banana compound powder: taking green bananas,performing thorough cleaning, performing cutting off, separating green banana peel from fruit flesh, placing the fruit flesh in a citric acid solution, performing soaking, then performing taking out,mixing the green banana flesh with passion fruit pulp in proportion, performing low-temperature pulping, then performing vacuum ultrasound drying, and then performing superfine grinding to obtain green banana compound powder; (2) preparing tablets: accurately weighing the green banana powder, lemon powder, mannitol and compound starch, performing primary and uniform mixing, and performing screening to obtain substances to be tabletted; and (3) performing tabletting and shaping: placing the substances to be tabletted in a constant-temperature constant-humidity fluidized bed, adding magnesium stearate, through air flowing, enabling the substances to be further uniformly mixed to form fine granules, then adding the fine granules in a tabletting machine, and performing tabletting to obtain thegreen banana tablets of which two sides are chamfered. The prepared green banana tablets are high in hardness, short in disintegration time, and balanced in nutrient value, and have high market promotion prospects.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Processing technology of instant domestic fungus composite soup material

ActiveCN104839807ASingle tasteChange the situation of insufficient nutritionFood preparationBiotechnologyNutrition

The invention discloses a processing technology of an instant domestic fungus composite soup material. The processing technology comprises raw material selection, cleaning, drying, crushing, mixing, sterilization and packaging. The processing technology has simple processes and a low cost. The instant domestic fungus composite soup material is rich in nutrients and has a delicious taste and a high added value.

Owner:苏州卫优知识产权运营有限公司

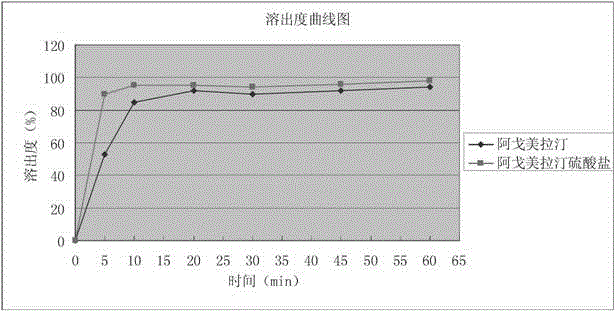

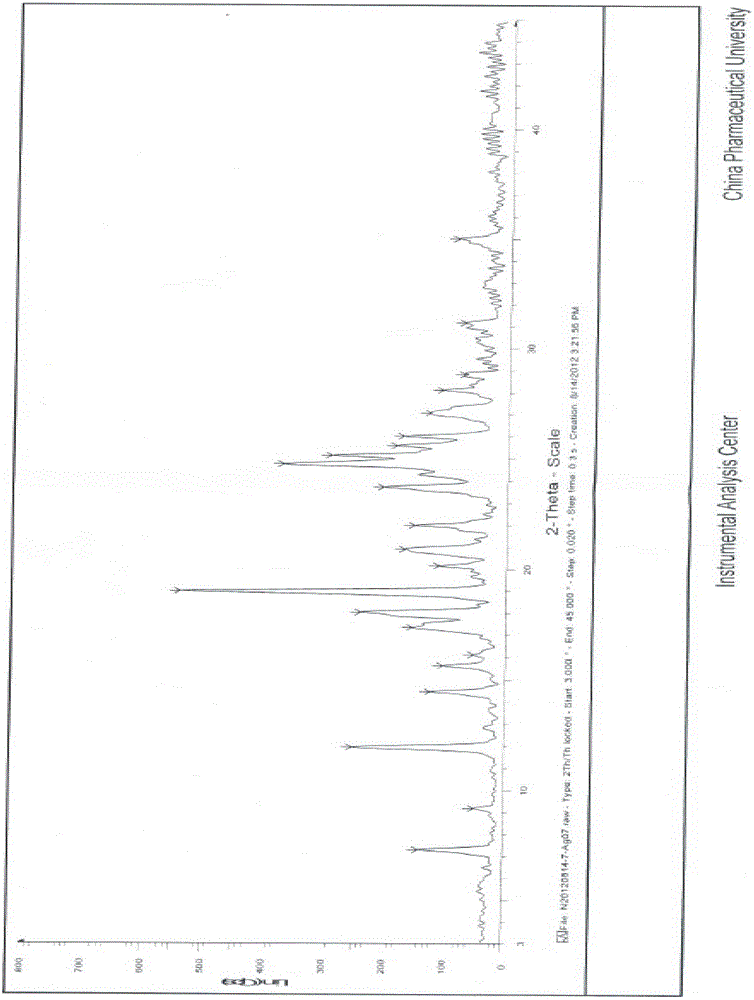

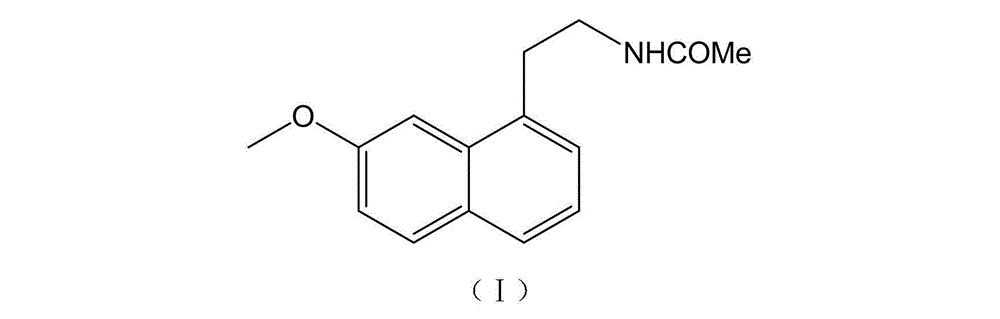

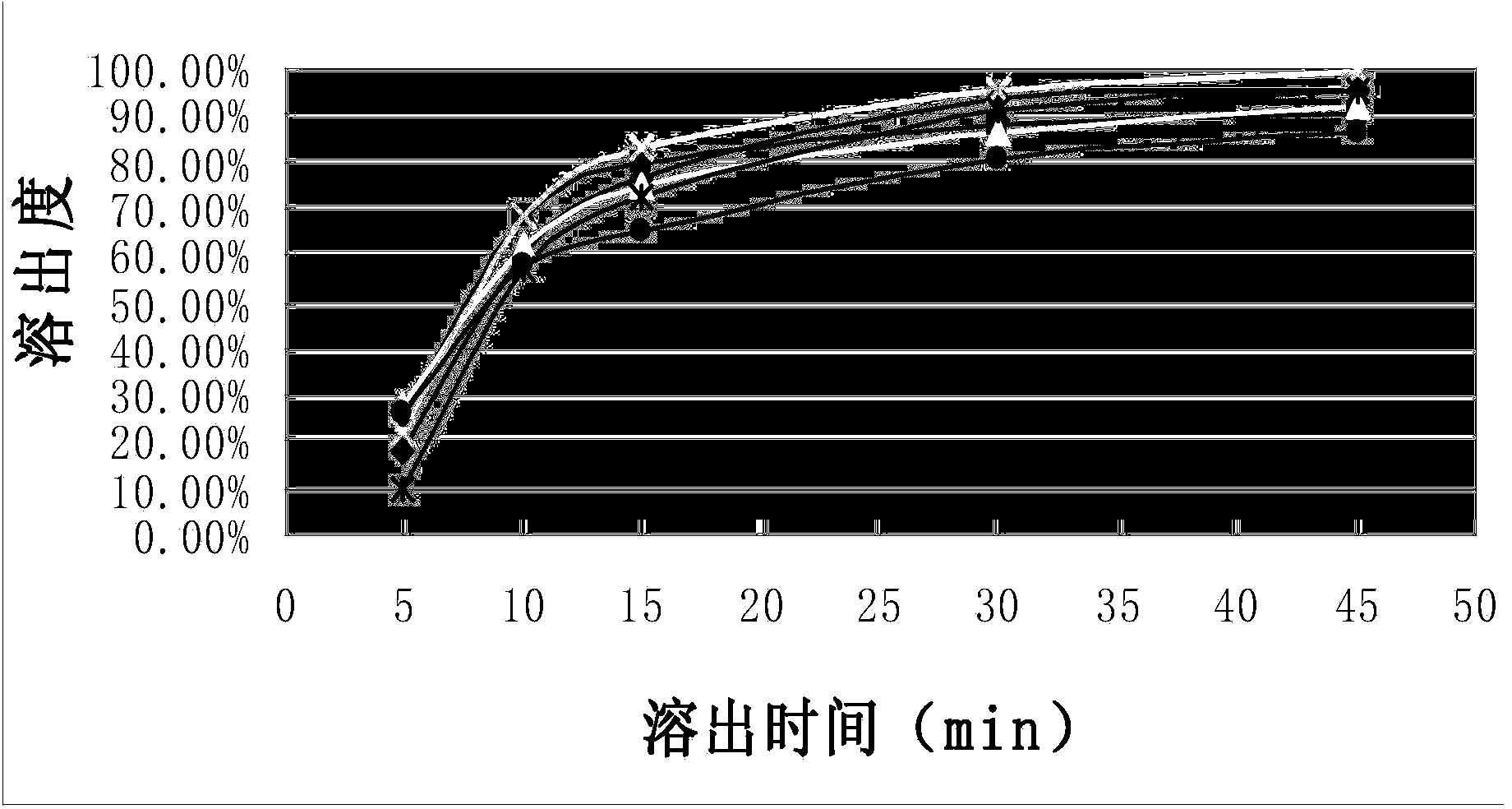

New crystal form I of agomelatine sulfate and preparation method thereof

InactiveCN102911075AHigh dissolution rateImprove bioavailabilityOrganic active ingredientsNervous disorderAlcoholAnti solvent

The invention relates to a new crystal form I of an agomelatine sulfate and a preparation method thereof. The preparation method of the crystal form I comprises the steps of heating and dissolving the agomelatine sulfate in a soluble solvent, slowly dripping into an anti-solvent to precipitate crystals, filtering and vacuum drying to obtain the crystal form I. The soluble solvent can be selected from alcohol and amide, and the anti-solvent can be selected from ester and alkane.

Owner:FUJIAN COSUNTER PHARMA

Microporous foam glass and preparation method thereof

InactiveCN107399913AImprove high temperature resistanceHigh compressive strengthGlass shaping apparatusAmmonia compoundsCompressive resistanceFiber

The invention discloses microporous foam glass and a preparation method thereof, and relates to the field of glass products. The foam glass is prepared from the following raw materials of crushed glass powder, mordenite zeolite, hyalophane mica, modified quartz powder, kaolin, titanium dioxide, sodium fluoride, reinforced fiber, adhesive, foaming agent and foam stabilizer. The preparation method comprises the following steps: smashing raw materials, melting, cooling, standing, foaming, annealing, foaming and polish. The production raw materials of the foam glass are wide in source, and are simple in a preparation process; the finished product of foam glass contains a large amount uniform, unique and enclosed micropores inside, so that the heat-insulation high temperature and compressive resistance of the foam glass product are improved remarkably, as well as long service life, wide application field and suitability for popularization and application are achieved.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

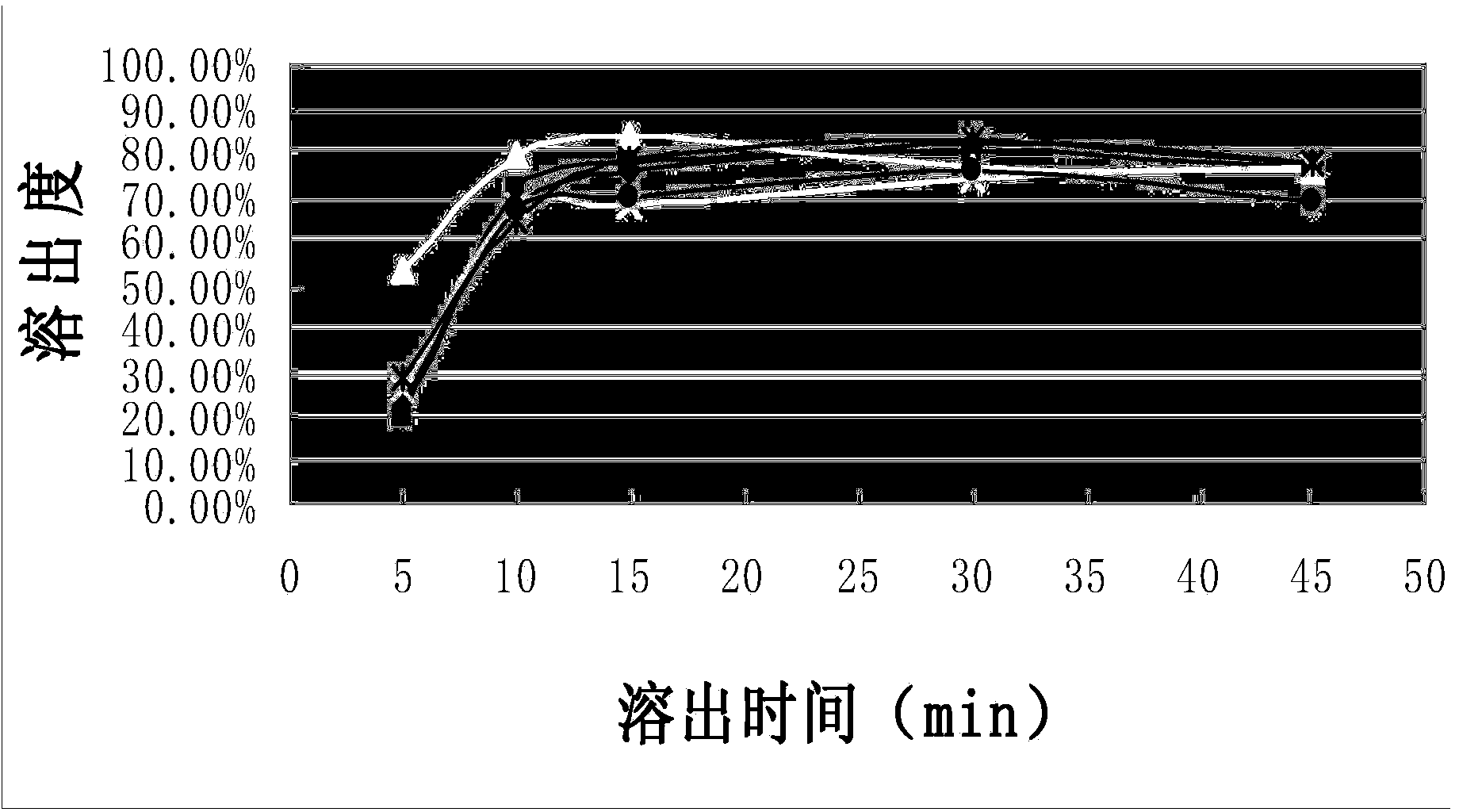

Flunarizine hydrochloride composition capsule and preparation method thereof

InactiveCN104069086AHigh dissolution rateImprove liquidityOrganic active ingredientsNervous disorderMolten statePolyethylene glycol

The invention relates to the field of medical technology, and discloses a flunarizine hydrochloride composition capsule and a preparation method thereof. The flunarizine hydrochloride composition capsule comprises flunarizine hydrochloride, polyethyleneglycol, talcum powder, magnesium stearate, lactose and starch. As auxiliary material composition is changed, that is, flunarizine hydrochloride is added into polyethyleneglycol which is in a molten state, and then uniformly mixed with other auxiliary materials in an equivalently progressive increasing manner, the dissolution rate and the flowability of the end product are improved remarkably.

Owner:周有财

Medicine composition for treating diabetes

InactiveCN1857368AGuaranteed the effect of blood sugar controlVulnerability to change usageOrganic active ingredientsMetabolism disorderPuerarinCurative effect

The present invention belongs to the field of medicine technology, and especially a kind of diabetes treating medicine composition and its preparation process and use. Specifically, the medicine composition is prepared with glibenclamide, puerarin, trichosanthes root and taurine. The medicine composition has high curative effect on diabetes and can lower the incidence rate of diabetes complication, including diabetic nephropathy, and its taurine can reduce the angle of repose of the medicine composition powder to smaller than 30 deg and improve the flowability of medicine composition powder.

Owner:JILIN SIHUAN PHARM CO LTD

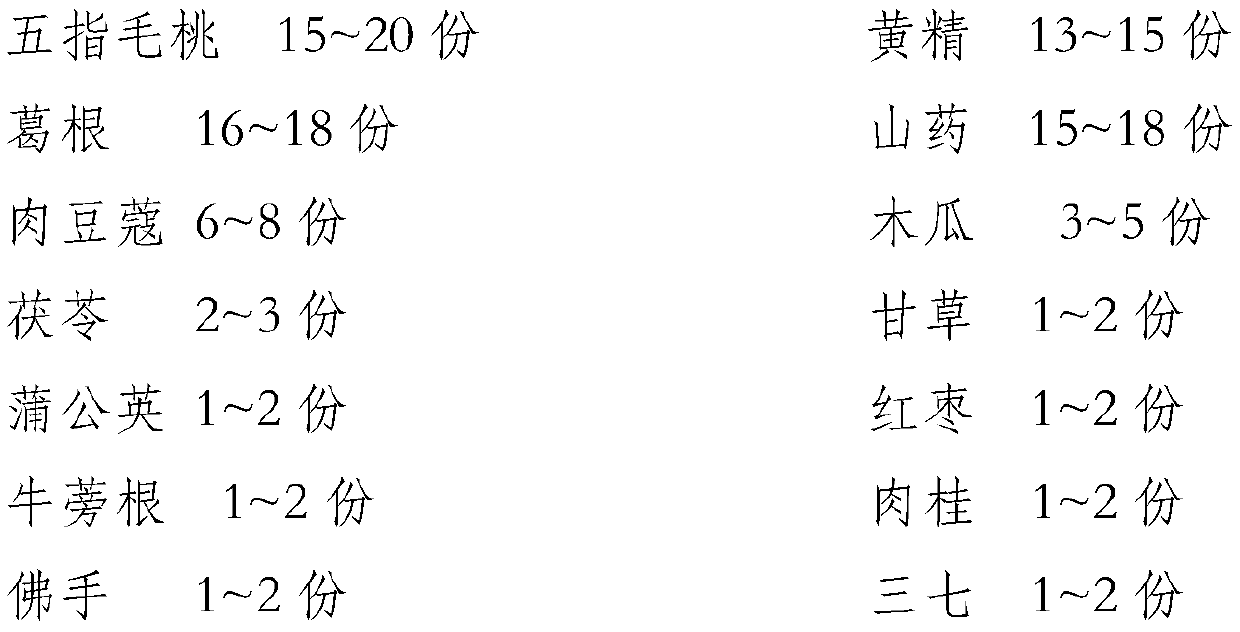

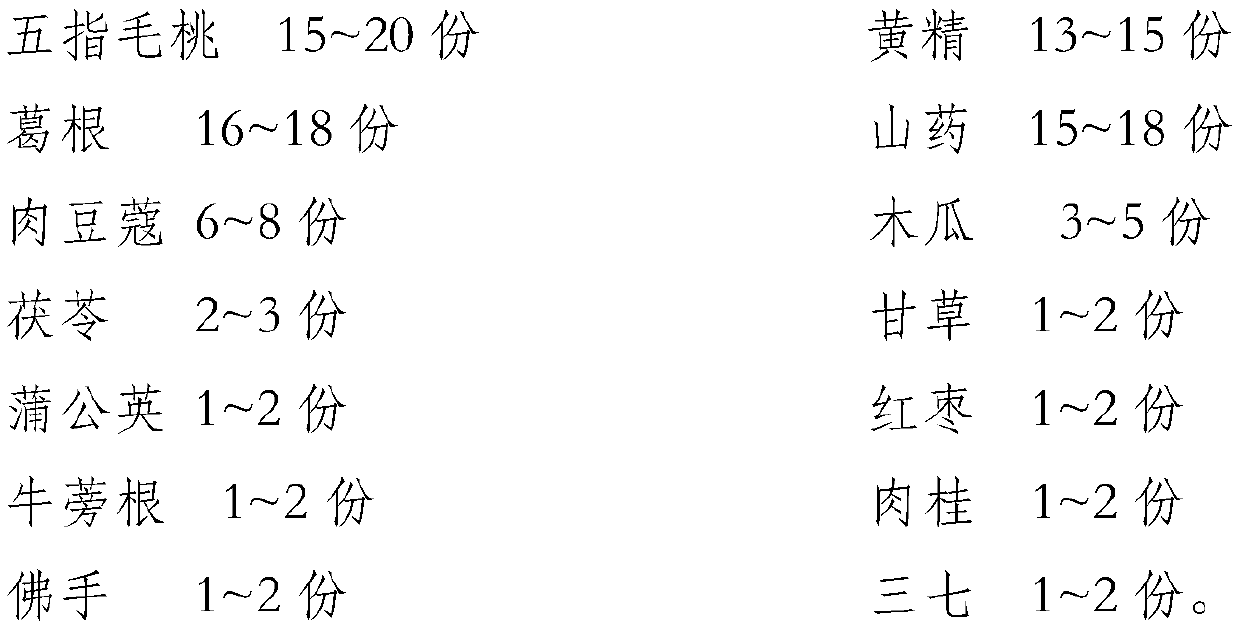

Preparation method and products of powdery soup bag with functions of clearing damp and expelling toxins

PendingCN110236164AImprove immunityHigh nutritional valueAntipyreticAnalgesicsMedicinal herbsLicorice roots

The invention discloses a preparation method and products of a powdery soup bag with functions of clearing damp and expelling toxins. The powdery soup bag is prepared from, by mass, 15-20 parts of radix fici simplicissimae, 13-15 parts of rhizoma polygonati, 16-18 parts of radix puerariae, 15-18 parts of common yam rhizomes, 6-8 parts of nutmeg, 3-5 parts of fructus chaenomelis lagenariae, 2-3 parts of poria cocos, 1-2 parts of licorice roots, 1-2 parts of herba taraxaci, 1-2 parts of fructus jujubae, 1-2 parts of burdock roots, 1-2 parts of cortex cinnamomi, 1-2 parts of fructus citrus sarcodactylis and 1-2 parts of radix notoginseng. The raw materials in the powdery soup are selected from medicinal herbs with the functions of fragrance enhancement and health care, and the product is convenient to eat and good in taste, and enhances the immunity of the human body while clearing the damp.

Owner:广西益丰元食品有限公司

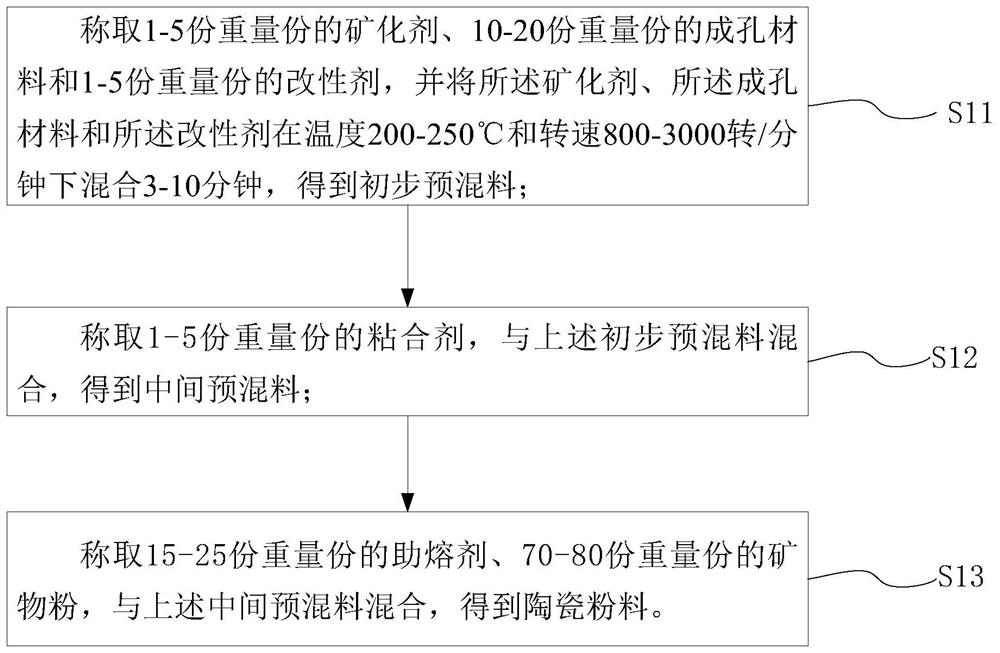

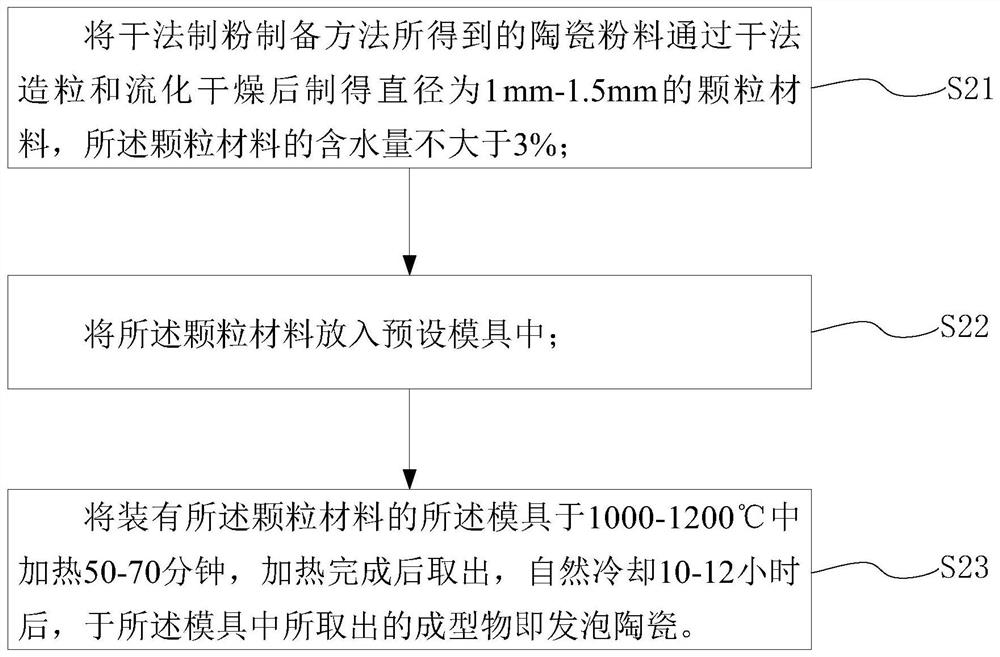

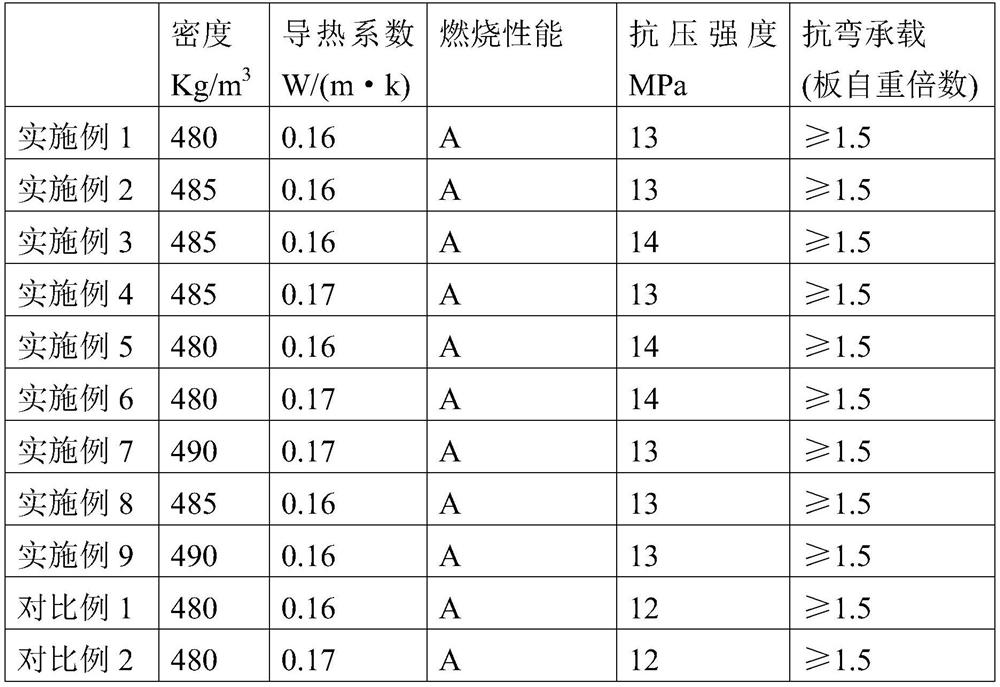

Preparation method of foamed ceramic and dry-method powder preparation method therefor

PendingCN113526977AImprove diffusion abilityImprove uniformityCeramic materials productionCeramicwareAdhesiveCeramic

The invention provides a preparation method of foamed ceramic and a dry-method powder preparation method therefor. The dry powder preparation method of the foamed ceramic comprises the following steps: weighing 1-5 parts by weight of a mineralizer, 10-20 parts by weight of a pore-forming material and 1-5 parts by weight of a modifier, and mixing the mineralizer, the pore-forming material and the modifier for 3-10 minutes at the temperature of 200-250 DEG C and the rotating speed of 800-3000 revolutions per minute to obtain a preliminary premix; weighing 1-5 parts by weight of an adhesive, and mixing the adhesive with the preliminary premix to obtain an intermediate premix; weighing 15-25 parts by weight of a fluxing agent and 70-80 parts by weight of mineral powder, and mixing the fluxing agent and the mineral powder with the intermediate premix to obtain the ceramic powder. The ceramic powder prepared through the dry-method powder preparation method is good in uniformity, the whole material mixing time is short, the time is saved, the material mixing efficiency is improved, and the economic benefits of enterprises are improved.

Owner:中集绿建环保新材料(连云港)有限公司 +3

A kind of processing technology of instant edible mushroom compound soup stock

ActiveCN104839807BExcellent nutrition and flavorExtended shelf lifeFood scienceEdible mushroomNutrient

The invention discloses a processing technology of an instant domestic fungus composite soup material. The processing technology comprises raw material selection, cleaning, drying, crushing, mixing, sterilization and packaging. The processing technology has simple processes and a low cost. The instant domestic fungus composite soup material is rich in nutrients and has a delicious taste and a high added value.

Owner:苏州卫优知识产权运营有限公司

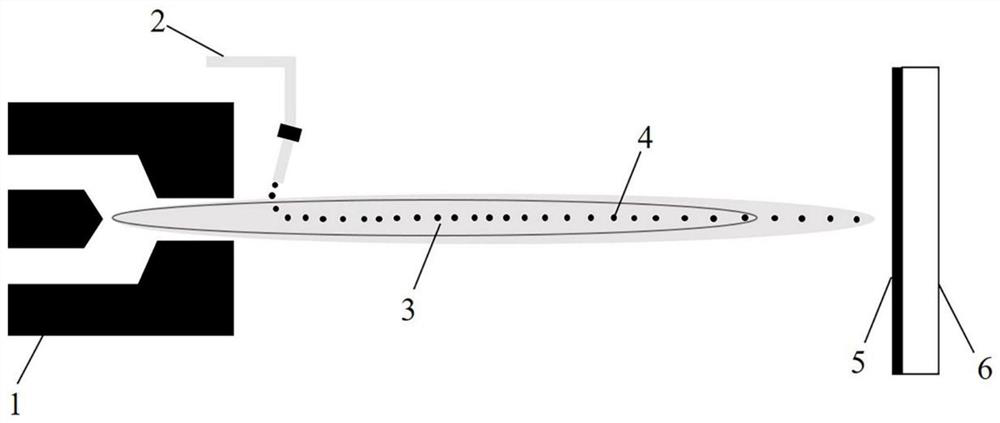

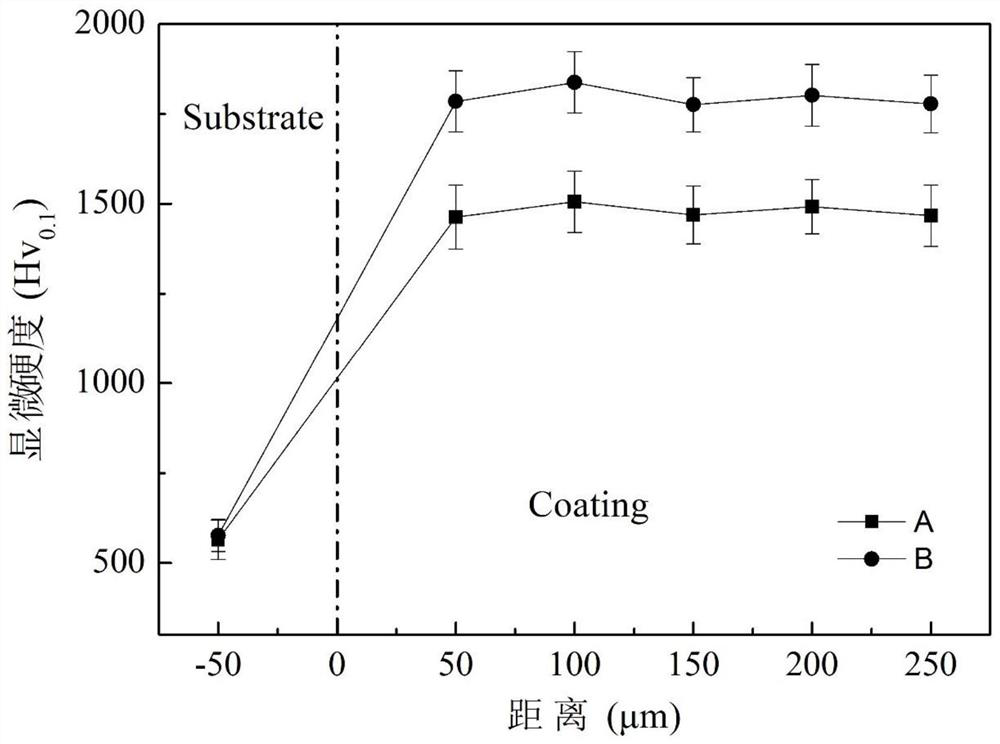

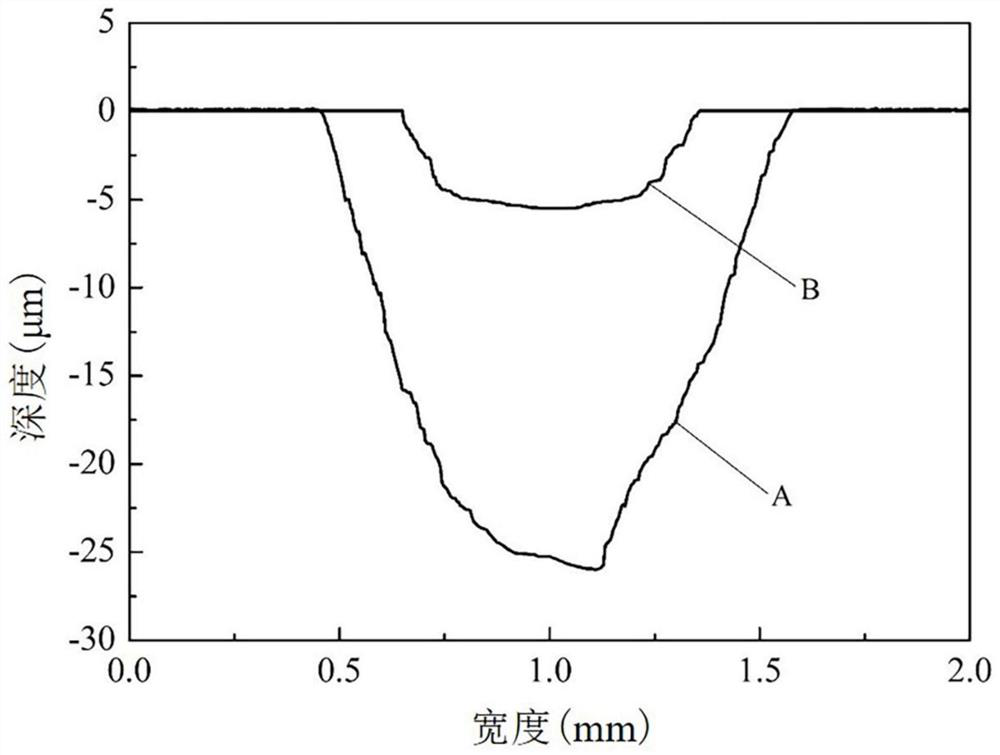

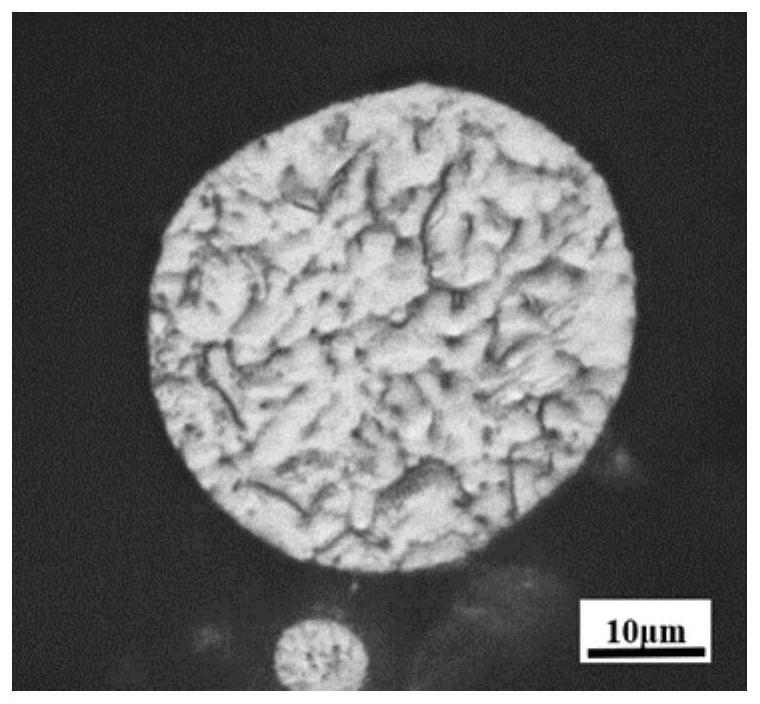

Preparation method of surface abrasion-resistant coating of floating clamping jaw of numerical control punching machine

InactiveCN111676439AHigh densityUnique "spherical" structureMolten spray coatingNumerical controlPunching

The invention discloses a preparation method of a surface abrasion-resistant coating of a floating clamping jaw of a numerical control punching machine. Firstly, chromium oxide ceramic particles and alow-melting-point additive are weighed according to the proportion of the coating and are evenly mixed; and then the high-performance abrasion-resistant coating is prepared on the surface of the clamping jaw after sand blasting through an atmospheric plasma spraying technology. The method solves the problem that a dovetail groove structure is used in a traditional floating clamping jaw of the numerical control punching machine and accordingly a plate is locally deformed in the clamping process. The low-melting-point glass powder additive in the mixed powder is of a unique spherical structure,so that the fluidity is better, the repose angle formed due to stacking is smaller, and material mixing is more uniform; a base material and a filler can be sufficiently dense, the density of the prepared coating is greatly improved, and problems of the pure chromium oxide coating in the using process are effectively solved, so that the tribology performance of the coating is better, the servicelife is longer, and the preparation cost is lower; and the thermal influence of the spraying process on the floating clamping jaw of the numerical control punching machine is small, and the structureand shape of a base body are not changed.

Quartz glass powder and preparation method thereof

InactiveCN108929041AReduce generationImprove stabilityGlass furnace apparatusGlass shaping apparatusPolyethylene glycolSilica gel

The invention provides a quartz glass powder and a preparation method thereof. The quartz glass powder comprises silicon dioxide powder, aluminum oxide, red lead, boric acid, barium oxide, bismuth oxide, titanium dioxide, tellurium dioxide, zincate, manganese dioxide, sodium oleate, polyglycol stearate and yttrium oxide. A preparation method of the silicon dioxide powder comprises the steps: removing impurities in quartz ores by using a color sorter, and carrying out wet ball milling, ore pulp is composed of quartz powder and a water solution, and the water solution contains an anionic surfactant and sodium silicate; carrying out drying under the condition of 300-500 DEG C for 2-4 h after ball milling, removing iron under strong magnetism, then, entering an acid pickling process, drying the quartz powder with acid pickling impurity removed impurities under the condition of 100-150 DEG C, and carrying out uniform dry mixing on the quartz powder and micropowder silica gel according to aproportion of 10:(0.5-1).

Owner:RIHONG SEMICONUCTING MATERIAL NANTONG CO LTD

Oral traditional Chinese medicine for treating fracture and tendon injury and preparation method of oral traditional Chinese medicine

PendingCN112402534AGood treatment effectImprove liquidityHeavy metal active ingredientsDispersion deliveryMedicinal herbsCurative effect

The invention discloses an oral traditional Chinese medicine for treating fracture and tendon injury and a preparation method of the oral traditional Chinese medicine. The pharmaceutical composition comprises the following components: 60 g of frankincense, 60 g of myrrh, 60 g of draconis resin, 60 g of earthworm, 60 g of muskmelon seed, 120 g of fortune's drynaria rhizome, 120 g of himalayan teasel root, 100 g of sappan wood, 240 g of Chinese angelica, and 120 g of pyrite (vinegar quenching). The oral traditional Chinese medicine is prepared from the pure herbal medicinal materials and is small in side effects, all the components give play to difference synergistic effects and act on fracture and tendon injury parts together, and the medicines are used according to the monarch, minister, assistant and guide principle, so that all the components can play the maximum role. Through process screening, the uniformity of particle size distribution is improved, the packing difference is reduced, the dissolution effect is improved, the bulk density is improved, the administration is more convenient, a repose angle is reduced, the flowability after dissolution is increased, the mixing is uniform, and the curative effect is ensured. Therefore, the oral traditional Chinese medicine has the characteristic of remarkable treatment effects on fracture and tendon injury.

Owner:王永全

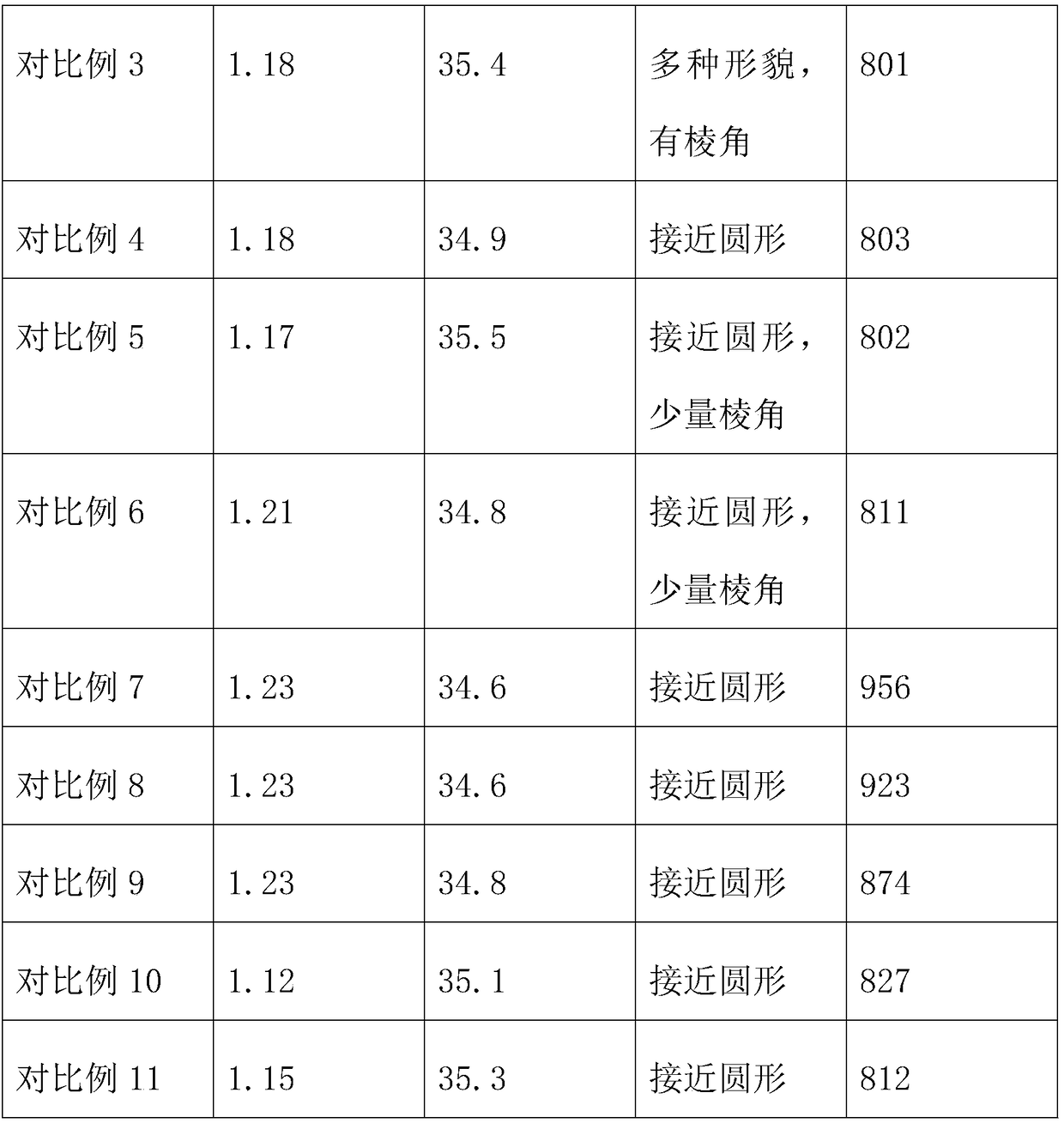

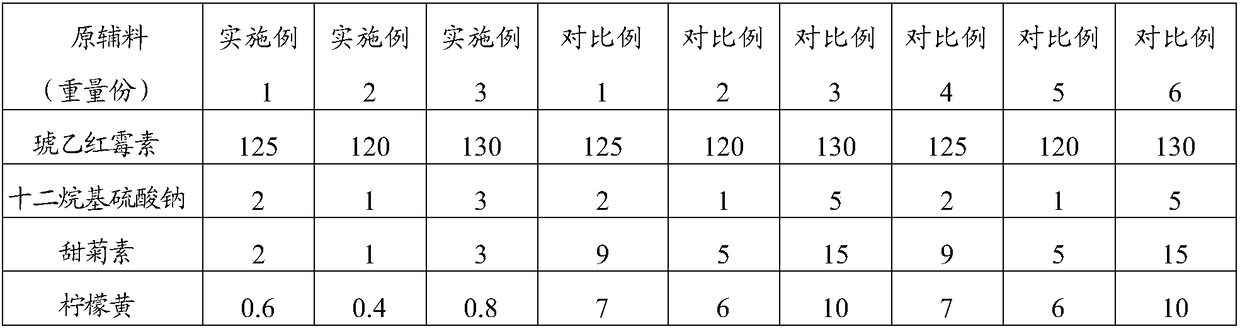

Erythromycin ethylsuccinate dry suspension and preparation method thereof

ActiveCN108403642AImprove dispersion stabilityEvenly dispersedAntibacterial agentsOrganic active ingredientsCelluloseCarboxymethyl starch

The invention provides erythromycin ethylsuccinate dry suspension and a preparation method thereof. The erythromycin ethylsuccinate dry suspension is prepared from the raw materials of 120 to 130 weight parts of erythromycin ethylsuccinate, 630 to 670 weight parts of saccharose powder, 10 to 20 weight parts of sodium alginate, 1 to 3 weight parts of steviosin, 5 to 15 weight parts of hydroxy propyl cellulose, 1 to 3 weight parts of lauryl sodium sulfate, 0.4 to 0.8 weight part of lemon yellow and 5 to 15 weight parts of sodium carboxymethyl starch. The sedimentation volume ratio F of the erythromycin ethylsuccinate dry suspension disclosed by the invention is very close to 1, a flocculation degree beta of the erythromycin ethylsuccinate dry suspension is about 6.0, and redispersibility ofthe erythromycin ethylsuccinate dry suspension is larger than or equal to 95%; thus, the suspension can be evenly dispersed in water, the problem that erythromycin ethylsuccinate dry suspension in theprior art can form much small micelle after water is added into the erythromycin ethylsuccinate dry suspension according to an instruction book is solved, clinical use experience is improved, and patient compliance is improved.

Owner:山西皇城相府药业股份有限公司

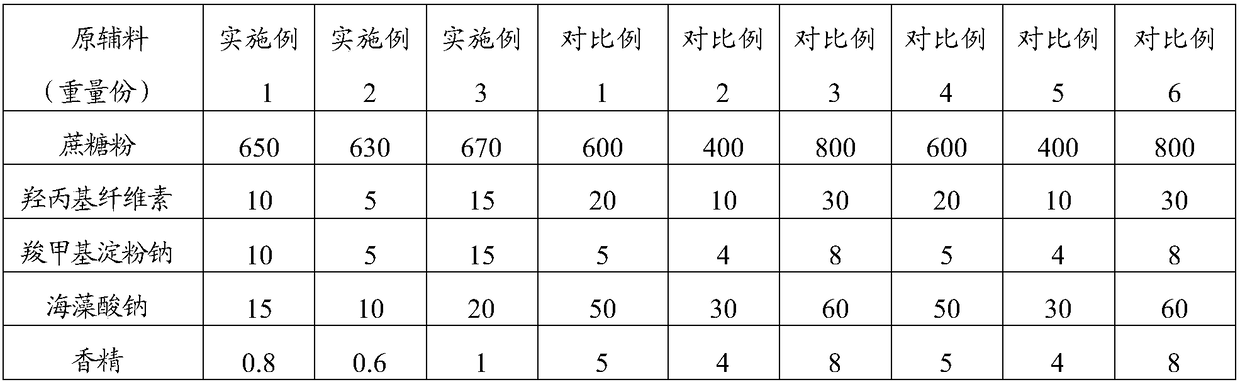

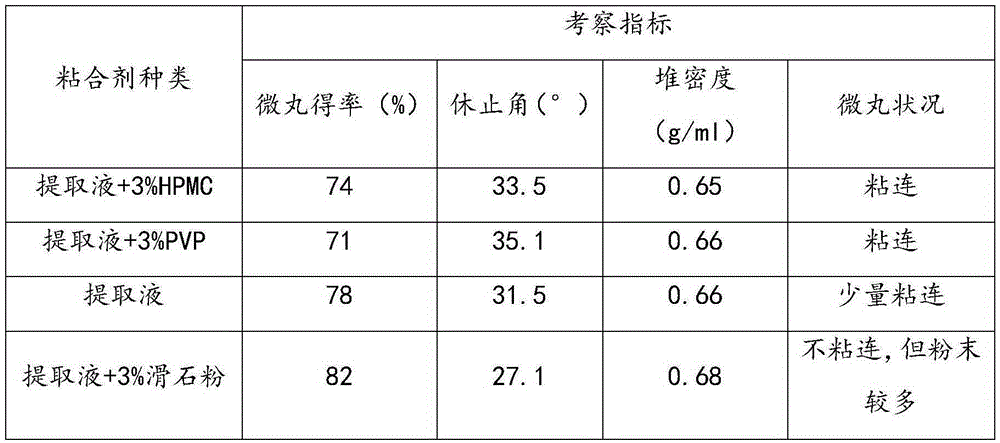

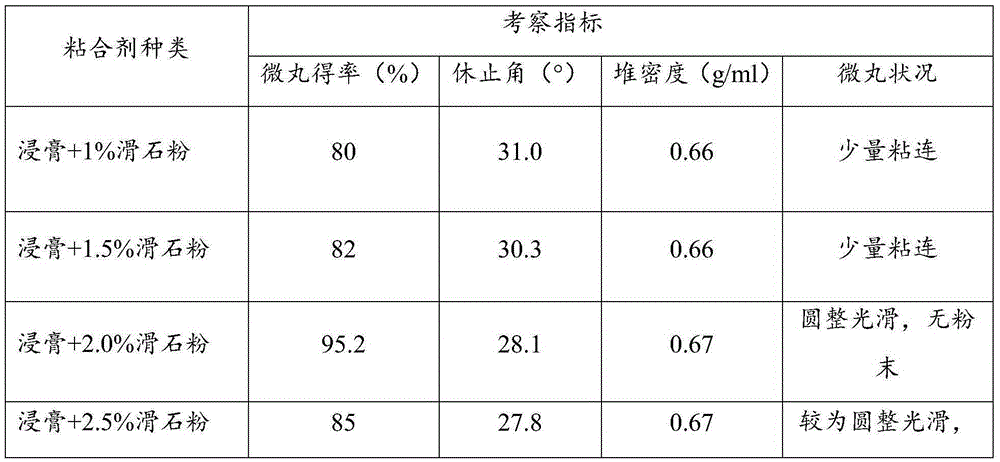

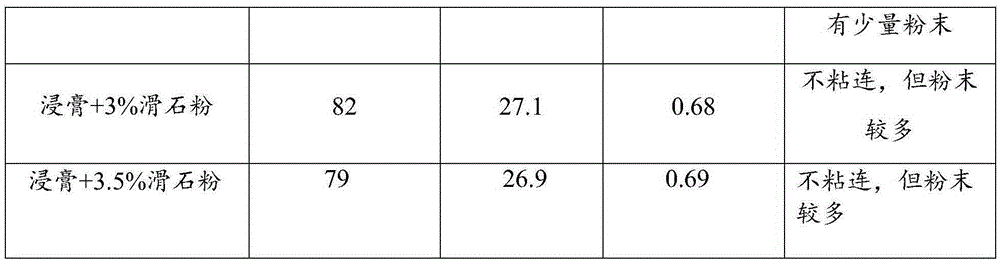

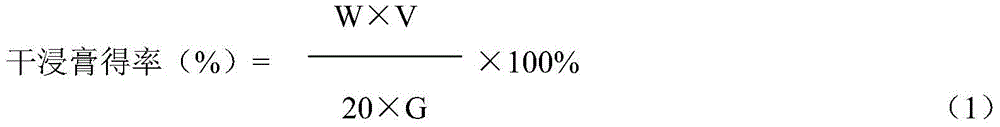

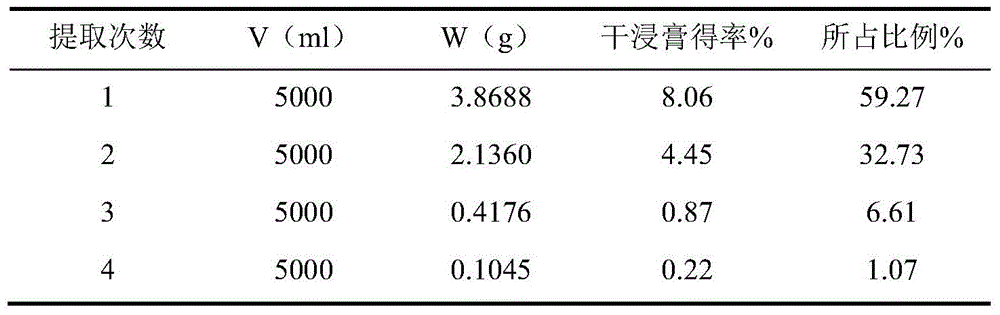

Preparation method and product of veterinary Qingfei powder pellets

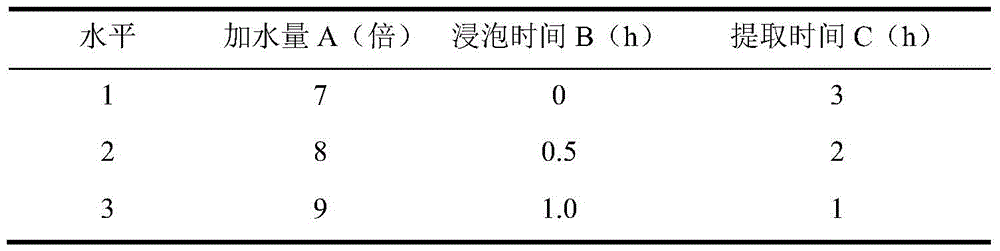

ActiveCN103705715BHigh yieldSmall angle of reposeAntiinfectivesGranular deliveryClinical efficacyFluidized bed

The invention discloses a method for preparing a veterinary lung-clearing pellet and a product thereof. The preparation method comprises the following steps: (1) extracting effective components of bulk drugs to prepare extract for later use; (2) preparing a pellet core; (3) adding talc powder into the extract, uniformly mixing to obtain a mixture, loading the mixture to the surface of the core in a spraying manner in a fluidized bed, and drying. According to the preparation method, process parameters of the veterinary lung-clearing pellet are optimally screened, and the prepared pellet has the advantages of high yield, roundness and smoothness, small rest angle and the like. Clinical effect verification for treating mycoplasma pneumoniae of swine indicates that the lung-clearing pellet prepared by the method has a remarkable clinical treatment effect on mycoplasma pneumoniae of swine, which is superior to the clinical curative effect of lung-clearing powder.

Owner:WUHAN HUAYANG ANIMAL PHARMA

A preparation method of traditional Chinese medicine composition for qi and blood deficiency

ActiveCN104138452BDisintegrates quicklyIncrease contentDigestive systemPharmaceutical non-active ingredientsSalvia miltiorrhizaMotherwort

The invention discloses a preparation method of a traditional Chinese medicine composition for deficiency of both qi and blood, and belongs to the technical field of traditional Chinese medicine. The method comprises the following steps: (1) taking motherwort, rock sugar grass and salvia miltiorrhiza, soaking in water, decocting twice, filtering, combining the filtrates, and concentrating to obtain a clear cream for future use; (2) placing the clear cream in a spray dryer (3) Add dextrin and ethanol to the clear paste powder to make a soft material, sieve, and then place it in a boiling dryer for drying and granulation; (4) After the granules are prepared Add glidant, mix and fill. The preparation method of the traditional Chinese medicine composition for qi and blood deficiency is simple, the product quality is stable, the content of active ingredients (such as stachydrine hydrochloride) is high and the yield of finished products is high. The capsule prepared by the method can disintegrate rapidly in the human body, and is convenient for the human body to absorb and utilize.

Owner:HENAN RUNHONG HERBAL PHARMA

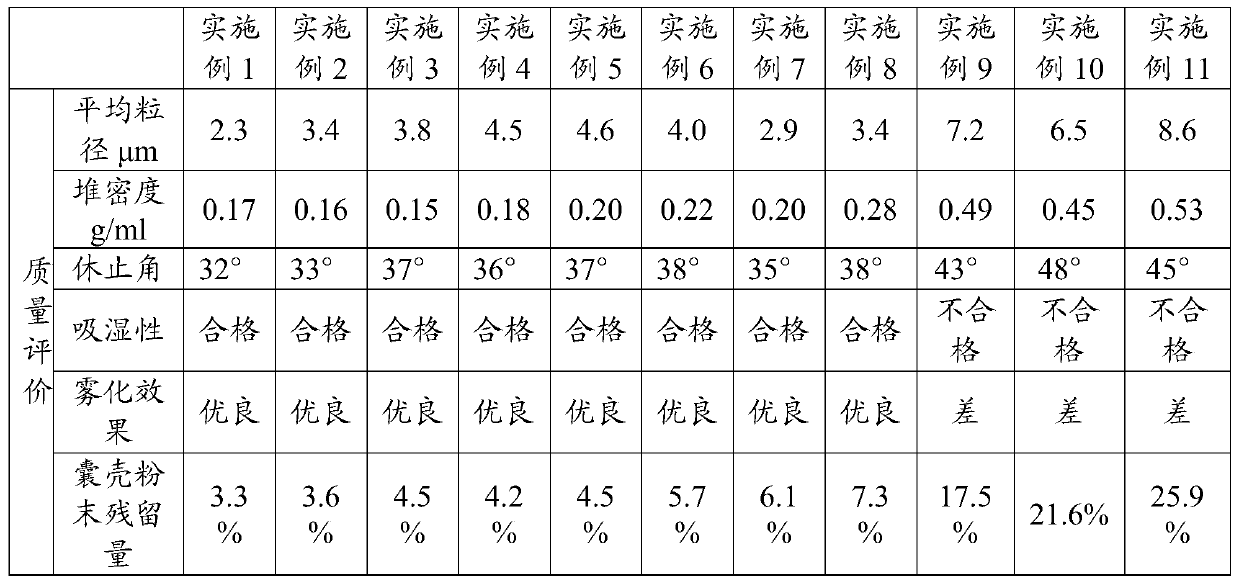

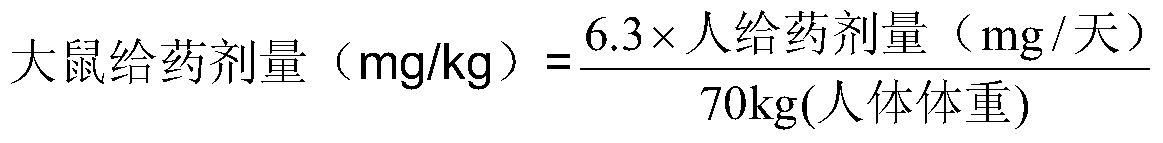

A kind of dapagliflozin inhalation powder mist and preparation method thereof

InactiveCN105796534BImprove securityImprove bioavailabilityOrganic active ingredientsMetabolism disorderSolubilityArginine

The invention relates to the technical field of medicine, and discloses a dapagliflozin dry powder inhalation. The dry powder inhalation contains dapagliflozin, carriers and amino acids, wherein the carriers are one or more than two materials from lactose, lecithin, phosphatidylchline and mannitol; and the amino acids are one or more than two materials from glutamic acid, aspartic acid, threonine, isoleucine, leucine and arginine. The carriers and the amino acids proper for the dapagliflozin are used and matched; the optimized mixture ratio is selected; and the obtained dapagliflozin dry powder inhalation enriches the types of dapagliflozin preparations and has the advantages of high safety, high bioavailability, high effect taking speed, low dosage, small powder particle diameter, low density, high solubility, high bulk density, good rest angle, high sprayability and moisture absorption difficulty.

Owner:HYBIO PHARMA

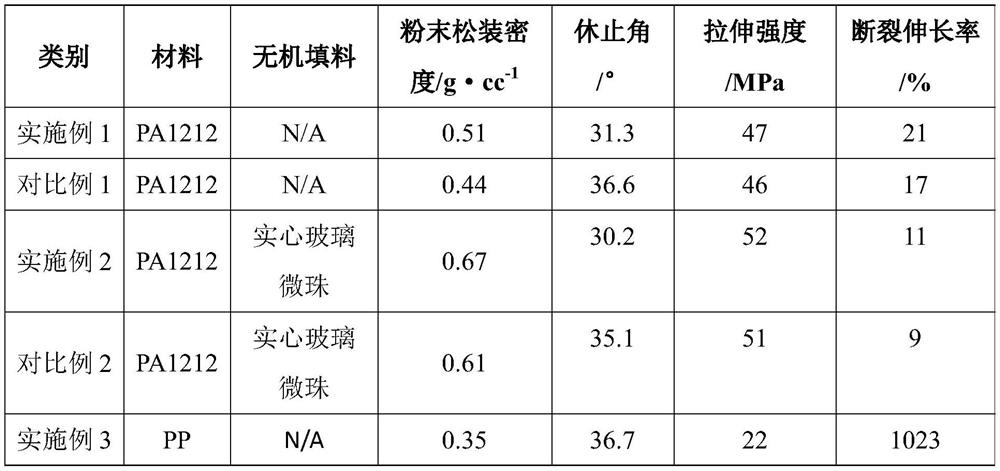

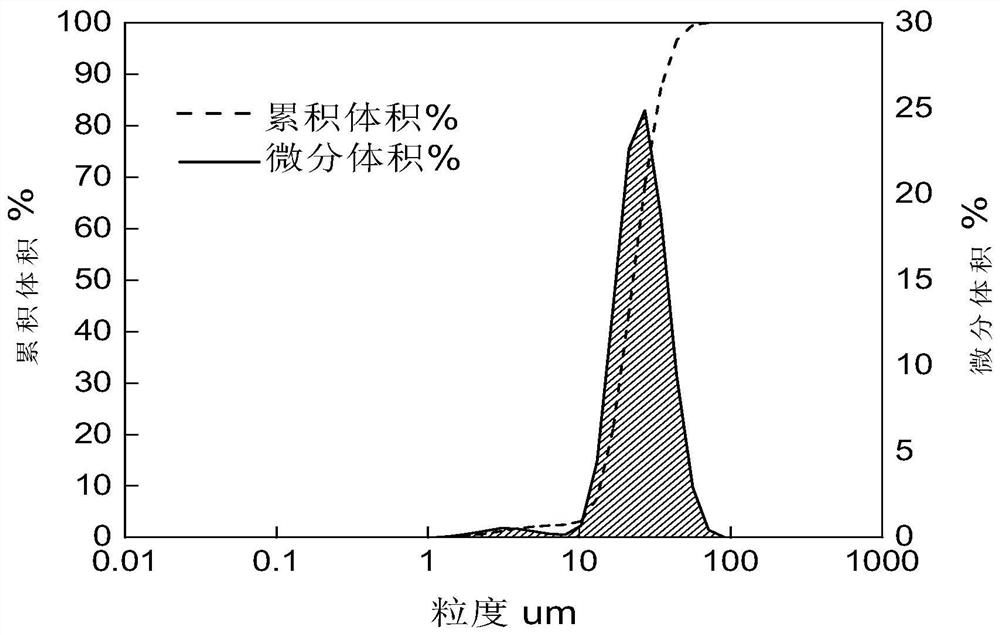

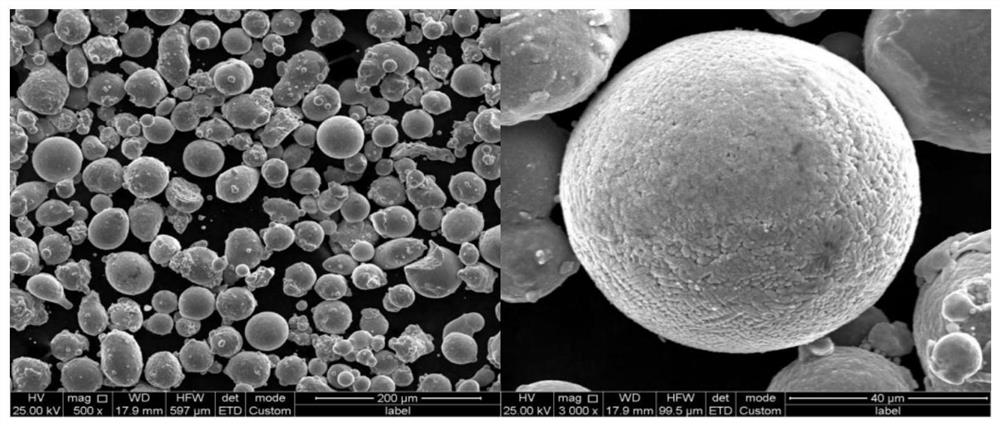

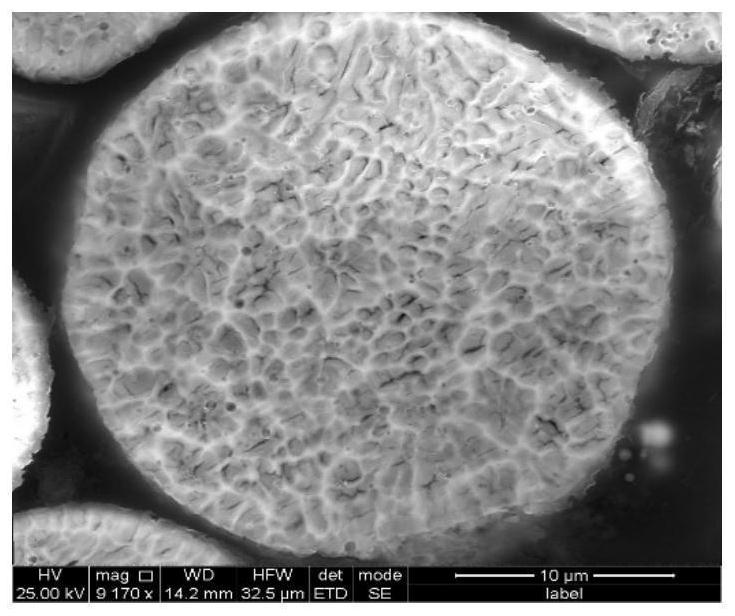

Polymer powder material for selective laser sintering and preparation method thereof

ActiveCN114349988ATakamatsuSmall angle of reposeAdditive manufacturing apparatusIncreasing energy efficiencySelective laser sinteringPolymer

The invention provides a preparation method of a high-molecular powder material for selective laser sintering, which comprises the following steps: adding 1-20 parts by mass of high-molecular powder and a powder additive into a high-speed stirrer, and preparing high-molecular powder lead powder through a high-speed stirring process, and adding the polymer powder guide powder, 50-99 parts by mass of polymer powder and 0-30 parts by mass of powder filler into a low-speed mixer, heating to 60-120 DEG C, continuously preserving heat, and preparing the polymer powder material through a low-speed stirring process, starting from slow stirring, spraying a part of water into the mixed powder in the stirrer at set time intervals by adopting a spraying method until the water with the set mass is completely used up, and continuously stirring and mixing until the stirring time reaches the set time, so as to obtain the polymer powder material. The polymer powder material has the advantages of high apparent density and good fluidity.

Owner:湖南华曙新材料科技有限责任公司

Formula of acid-proof cancer-prevention product

InactiveCN111419911AGood dissolution effectHigh bulk densityMetabolism disorderAlgae medical ingredientsFormularyGlycerol

The invention discloses a formula of an acid-proof cancer-prevention product. The acid-proof cancer-prevention product consists of the following components in parts by weight: 1 g of SP60, 1.2 g of TW60, 4 g of 7501, 1.5 g of C16 / 18, 0.2 g of methyl ester, 0.1 g of propyl ester, 3 g of 2EHP, 15 g of 26# white oil, 3 g of an amino acid humectant, 72 g of water, 5 g of glycerol, 0.15 g of 940, 025 gof JINKOU305, 0.05 g of rose scent, 0.2 g of carmine, 0.15 g of TEA and 0.4 g of Jiema C. According to the invention, seaweed and raw rhubarb roots are adopted to prepare powder liquid, and the components exert an effect of differences and cooperation and act on the skin of a patient together. The medicines are applied according to the principle of monarch, minister, assistant and guide, so thatthe components can exert effects to the maximum extent. Through process screening, uniformity of particle size distribution is improved, difference of filling amounts is reduced, the dissolution effect is improved, and the bulk density is improved. The acid-proof cancer-prevention product is more convenient to take, the angle of repose is reduced, the fluidity is increased, mixing is uniform, andthe curative effect is ensured. Therefore, the acid-proof cancer-prevention product has obvious effects of preventing acid-base imbalance and preventing cancers.

Owner:余荣华

Manganese-copper damping alloy powder based on slm process and preparation method thereof

ActiveCN111057922BImprove mechanical propertiesImprove damping performanceAdditive manufacturing apparatusTransportation and packagingManufacturing technologyNuclear power

A manganin-copper damping alloy powder based on an SLM process and a preparation method thereof belong to the technical field of metal materials for additive manufacturing. The chemical composition of the powder is C: ≤0.15%, Ni: 4.9-5.2%, Si: ≤0.15%, Fe: 1.8-5.0%, Cu: 20-23%, P: ≤0.03%, S: ≤0.06%, the balance is Mn and unavoidable impurity elements. The manufacturing process includes: master alloy preparation, vacuum induction melting gas atomization method VIGA powder making, mechanical vibration and airflow classification sieving and collection under the protection of inert gas. Compared with the existing technology, the powder has high sphericity, high bulk density, small angle of repose, good fluidity and high yield of fine powder of 15-53 μm, and can be used in the fields of aerospace and ship additive manufacturing Shock-absorbing and damping parts can also be extended to the field of additive manufacturing of precision electronic instruments for transportation and nuclear power, which has broad market prospects.

Owner:CENT IRON & STEEL RES INST

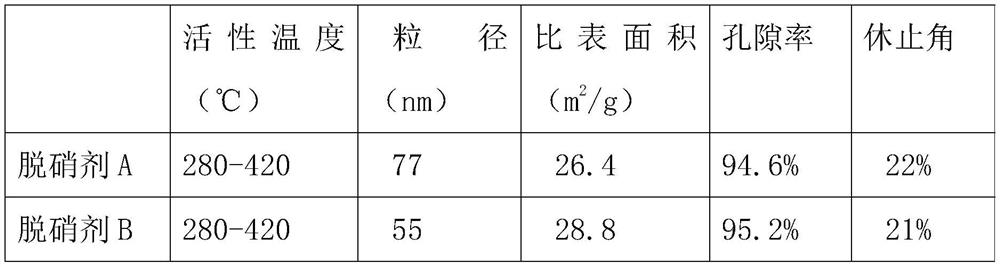

Preparation method and application of solid nano calcium carbonate denitration agent with high fluidity, high efficiency and low by-products

PendingCN114558441ASmall angle of reposeImprove liquidityGas treatmentDispersed particle separationSide productCalcium carbonate

The invention discloses a preparation method and application of a solid nano calcium carbonate denitration agent with high fluidity, high efficiency and low by-products, and belongs to the technical field of flue gas purification and denitration. The preparation method comprises the following steps: S1, preparing hyperdispersant slurry; s2, preparing a nano calcium carbonate solution; s3, mixing the nano calcium carbonate solution, the hyperdispersant slurry, polystyrene, boric acid ester and stearic acid to obtain a first product; s4, the first product is placed on the surface of a filter press to be subjected to filter pressing, the first product is washed with pure water during filter pressing, and a second product is obtained; s5, the second product is put into a granulator for granulation forming, a binder is put into the granulator during granulation, and the denitration agent can be obtained. Compared with a traditional denitration agent, the prepared denitration agent is smaller in particle size and angle of repose, has high fluidity, is prevented from being blocked in a pipeline, has the denitration efficiency far higher than that of the traditional denitration agent, and is more practical.

Owner:通化鑫鸿新材料有限公司

A processing method for improving the digestibility and brewability of instant brown rice flour

The invention discloses a processing method for improving digestibility and reconstituability of instant brown rice powder. The processing method comprises the following steps: (1) germinating rice and then removing rich husk so as to obtain germinated brown rice; (2) crushing the germinated brown rice, sieving the crushed germinated brown rice with a 60-mesh sieve, sprinkling a high-temperature alpha-amylase weak solution into obtained brown rice powder, adjusting moisture content to 10 to 20%, carrying out uniform mixing, then carrying out sealing with a sealing bag, placing the sealing bag in a refrigerator with a temperature of 4 DEG C and balancing moisture for 10 to 20 h, wherein the sprinkling amount of the alpha-amylase weak solution is 40 to 60 U / g, i.e., 40 to 60 U units of the alpha-amylase weak solution is sprinkled into each g of the brown rice powder; and (3) after moisture balancing, carrying out extrusion cooking and crushing so as to obtain the instant brown rice powder. According to the invention, through effective combination of germination, enzymatic hydrolysis with high-temperature alpha-amylase and extrusion cooking, digestibility and reconstituability of the instant brown rice powder are improved to a greatest extent.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

A kind of preparation method of camphor essential oil soluble powder

ActiveCN110613750BSmall angle of reposeGood fluidity of powderAntibacterial agentsPowder deliveryAnhydrous ethanolAlcohol

The invention belongs to the field of veterinary medicine and discloses a preparation method of a soluble powder of camphor essential oil. The camphor essential oil is dissolved in absolute ethanol to obtain material liquid A; the solidified carrier is dissolved in water to obtain material liquid B; material liquid A and material liquid B are mixed evenly to obtain material liquid C; wherein, in terms of mass ratio, camphor essential oil: Absolute ethanol=1:(1~2), camphor essential oil:solidified carrier=1:(2~4), water:total mass of camphor essential oil and solidified carrier=(2~4):1; The solidification carrier is one of calixarene and gum arabic, or a mixture of the two; the material liquid C is ultrasonically obtained to obtain the material liquid D; the material liquid D is vacuum-dried, and the dried product is the soluble powder of camphor essential oil. The invention screens out the unique solidification carrier of camphor essential oil, and invents the soluble powder of camphor essential oil; the invention is a solid soluble powder with a low angle of repose, good powder fluidity, fast dissolution speed, no stratification and no precipitation , easy to use and widely used.

Owner:HENAN SOAR VETERINARY PHARMA +1

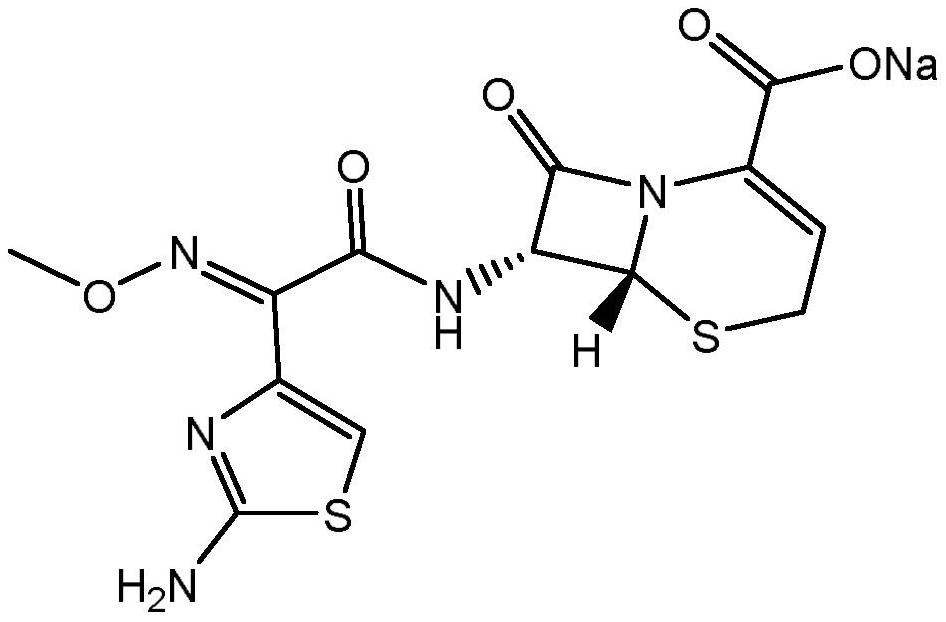

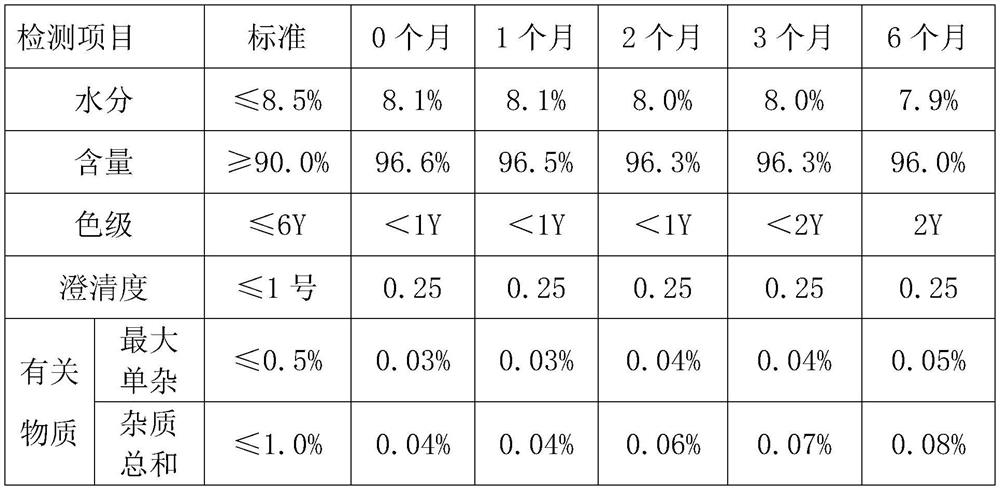

A kind of preparation method of ceftizoxime sodium for injection

ActiveCN111777625BEasy to packQuality improvementOrganic chemistryActivated carbonCeftizoxime Sodium

The invention relates to a preparation method of ceftizoxime sodium for injection, which belongs to the technical field of medicine. The method comprises the following steps: (a) reducing the temperature of the purified water to 0‑5°C; adding ceftizoxime acid to the purified water, and adding a buffer solution; (b) adding a salt-forming agent to the solution obtained in step (a), controlling The temperature is 0-5°C, stir until it dissolves; (c) add sodium chloride to the solution obtained in step (b), and stir until it dissolves; (d) add activated carbon to the filtrate obtained in step (c) for decolorization, decolorization Then filter; (e) Control the temperature of the solution obtained in step (d) to 13-15°C, add ethanol for the first time, then add ceftizoxime sodium seed crystals, and grow crystals. After a large amount of crystals are produced, add ethanol again, cool down and continue to grow crystals , filtered, washed, and dried to obtain ceftizoxime sodium powder; (f) aseptically subpackaging the ceftizoxime sodium powder obtained in step (e) to obtain ceftizoxime sodium powder for injection. The product is easy to pack for powder injection preparations.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

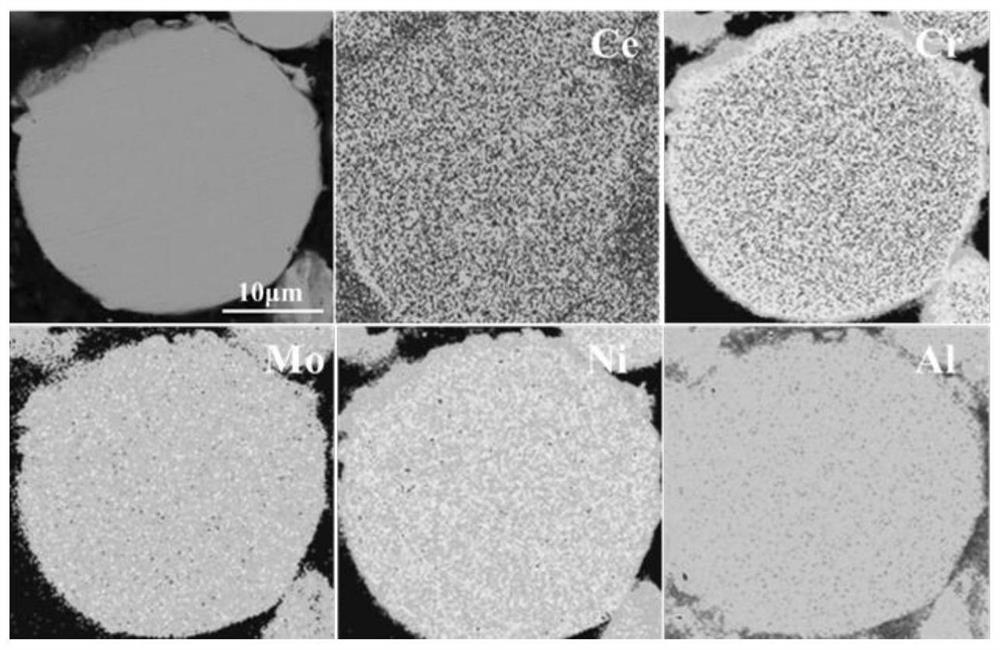

High-strength stainless steel powder for SLM, preparation method and printing process of high-strength stainless steel powder

ActiveCN114393206AHigh yield of fine powderHigh bulk densityAdditive manufacturing apparatusTransportation and packagingMetallic materialsSS - Stainless steel

The invention discloses high-strength stainless steel powder for SLM, a preparation method and a printing process thereof, belongs to the field of metal materials for additive manufacturing, relates to the high-strength stainless steel powder for SLM, the preparation method and the printing process thereof, and solves the problems that the gas content, especially the oxygen content, in existing vacuum gas atomization powder is too high; and the requirements for high strength and high plasticity and toughness of the SLM printed stainless steel part cannot be met. The high-strength stainless steel powder for SLM comprises the following chemical components in percentage by mass: less than or equal to 0.04% of C, less than or equal to 0.05% of Si, less than or equal to 0.05% of Mn, 12.5-13.5% of Cr, 7.5-8.5% of Ni, 2.0-2.5% of Mo, 1.0-1.15% of Al, 0.02-0.08% of Ce, less than or equal to 0.005% of P, less than or equal to 0.002% of S, less than or equal to 0.030% of O, less than or equal to 0.003% of N and the balance of Fe and inevitable impurities. The particle size range is 15-53 [mu] m. The density of the final SLM printed part reaches 99.8% or above, the tensile strength is larger than or equal to 1400 MPa, the yield strength is larger than or equal to 1360 MPa, the ductility is larger than or equal to 13%, the percentage reduction of area is larger than or equal to 57%, the U-shaped impact energy is larger than or equal to 100 J, and the use requirements for high strength and high plasticity and toughness of the 3D printed stainless steel part are met.

Owner:CENT IRON & STEEL RES INST

A kind of preparation technology of green banana tablet

ActiveCN108783296BReduce browningImprove antioxidant capacityPill deliveryFood dryingBanana powderNutritive values

The invention discloses a preparation process of green banana tablet, which comprises the following steps: (1) preparation of green banana compound powder: take green banana, wash and cut off, separate green banana skin from pulp, place the obtained pulp in After soaking in the citric acid solution, take it out, mix the green banana pulp and passion fruit pulp in proportion, perform low-temperature beating, then carry out vacuum ultrasonic drying, and after ultrafine pulverization, the green banana compound powder is obtained; (2) tablet Ingredients: Accurately weigh green banana powder, taro powder, mannitol, and compound starch, perform preliminary mixing, and sieve to obtain the material to be compressed; (3) Tablet forming: place the material to be compressed at a constant temperature In the wet fluidized bed, magnesium stearate is added, and the material is further mixed evenly into fine particles through air flow, and then put into a tablet machine to be pressed into green banana tablets with chamfers on both sides. The green banana tablet prepared by the invention has high hardness, short disintegration time and balanced nutritional value, and has broad market promotion prospects.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

A kind of production process of anhydrous calcium hydrogen phosphate of medicinal adjuvant with direct pressure function

ActiveCN113548653BSmall particle size differenceGood direct pressure effectPhosphorus compoundsCalcium hydroxideO-Phosphoric Acid

The invention belongs to the technical field of the synthesis of pharmaceutical excipients, in particular to a production process of anhydrous calcium hydrogen phosphate for pharmaceutical excipients with a direct pressure function. In the present invention, spherical anhydrous calcium hydrogen phosphate is finally obtained through the five-step operations of preparing calcium hydroxide slurry, preparing dilute phosphoric acid, neutralization reaction, solid-liquid separation and beating, and spray drying and screening. Fluidity to meet the technological requirements of direct compression tablets. The invention has the following advantages: in the production process of anhydrous calcium hydrogen phosphate, a crystallization inhibitor is used, and a rapid cooling operation is used to directly obtain anhydrous calcium hydrogen phosphate crystals, instead of first obtaining water-containing calcium hydrogen phosphate crystals and then removing crystal water, Combined with the spray drying process, the final anhydrous calcium hydrogen phosphate product has a suitable particle size and a regular spherical shape, which meets the requirements of direct compression tablets.

Owner:HUZHOU ZHANWANG PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com