Quartz glass powder and preparation method thereof

A technology of quartz glass powder and silica powder, which is used in glass manufacturing equipment, glass furnace equipment, glass molding and other directions to achieve the effects of improving bulk density and fluidity, reducing waste acid production, and increasing bulk density and slidability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

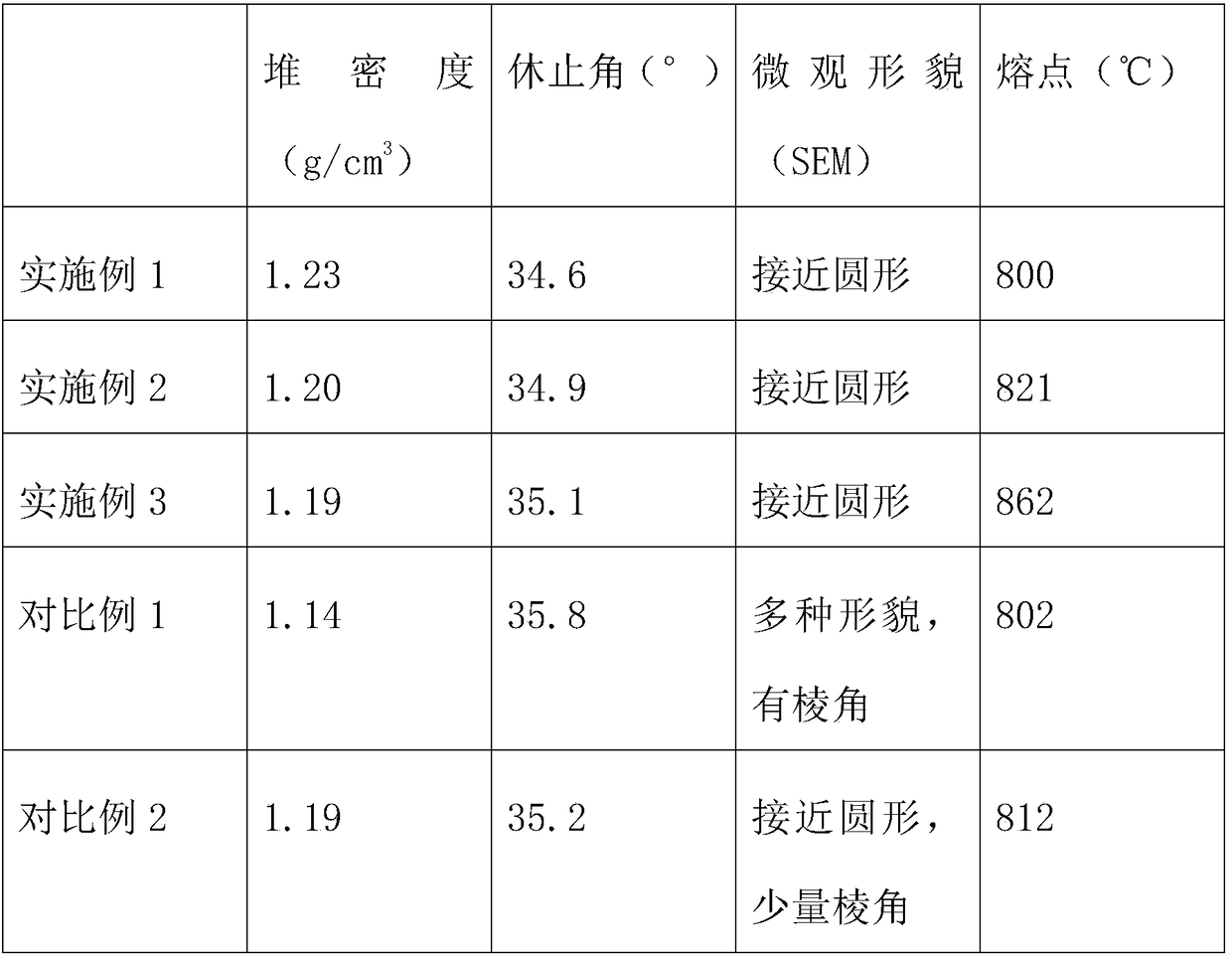

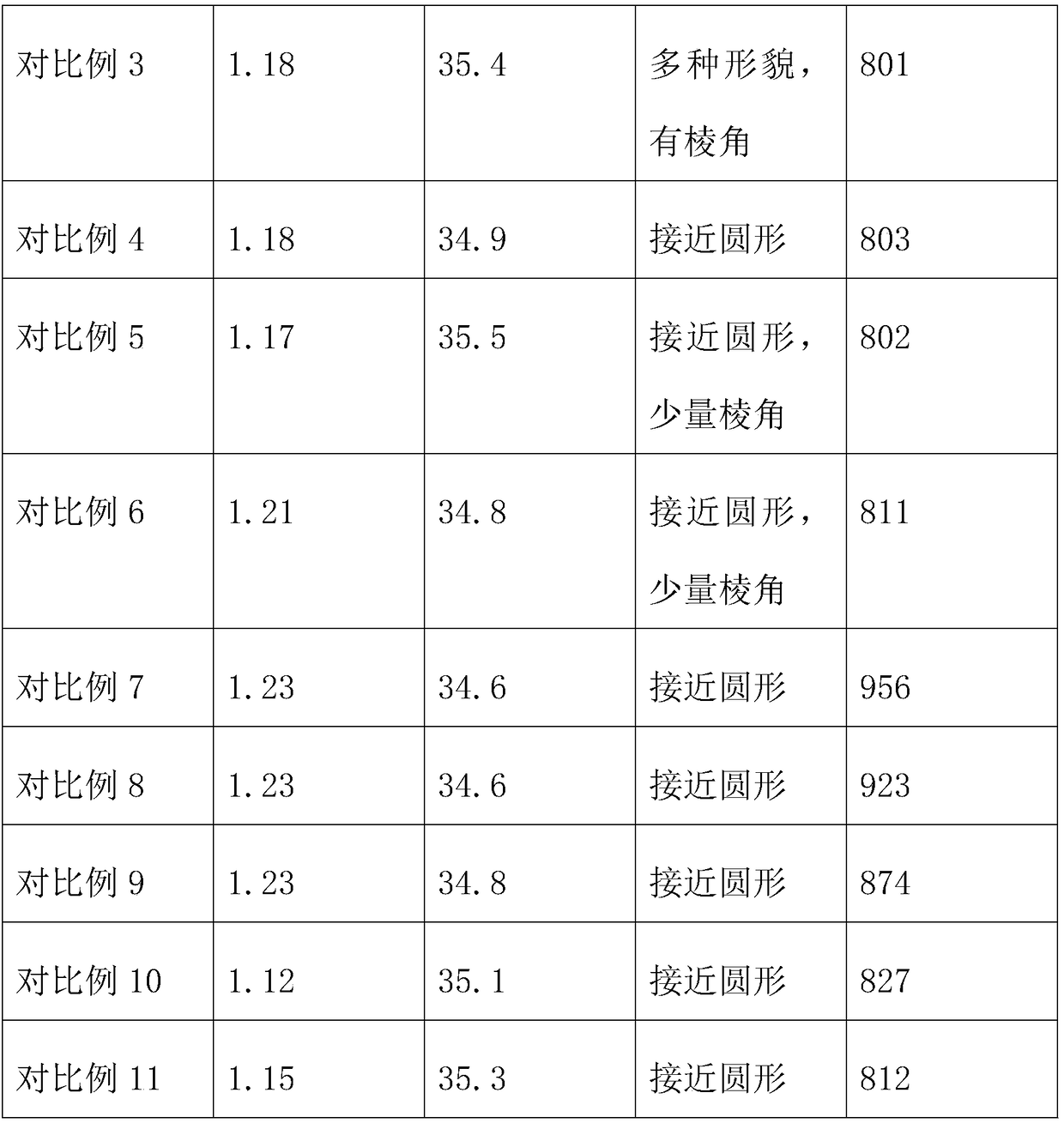

Embodiment 1

[0020] (1) Select quartz ore with a silica grade ≥ 95% and an average diameter of 2-5 mm after crushing, first use a color sorter to remove impurities so that the silica grade in the quartz powder is increased by more than 99.5%; (2) Color sorting The finished product enters a ball mill for wet ball milling. The ore pulp is composed of quartz powder and an aqueous solution in parts by mass of 4.5:1. The aqueous solution contains 1.5% by mass of anionic surfactant and 3% by mass of sodium silicate. The pH of the aqueous solution is 11 , the ball milling concentration is at 45% by mass, the ball mill rotating speed is 125 rpm, and the ball milling time is 3 hours. The volume of balls in the ball mill accounts for 2 / 3, and the ball ratio is as follows: 40mm balls account for 10%, 30mm balls account for 50%, and 20mm balls account for 50%. The ball accounts for 40%, and the ball mill and the 160 mesh high-frequency fine sieve form a closed circuit, and the products with unqualified...

Embodiment 2

[0023] A kind of quartz glass powder, it is characterized in that: (1) selects the quartz ore of silicon dioxide grade ≥ 95% and the average diameter after crushing is 2-5mm, first adopts color sorter to remove impurities to make the silicon dioxide grade in the quartz powder The improvement is greater than 99.5%; (2) the color sorted finished product enters the ball mill for wet ball milling, and the ore pulp is composed of quartz powder and an aqueous solution at 5:1 by mass, and the aqueous solution contains 1% by mass of anionic surfactant, 4% by mass of silicon Na2SO4, the pH of the aqueous solution is 10, the ball mill concentration is 50% by mass, the ball mill speed is 100 rpm, and the ball mill time is 4 hours. The volume of balls in the ball mill accounts for 2 / 3, and the ball ratio is as follows: 40mm balls account for 10%, 30mm balls accounted for 50%, 20mm balls accounted for 40%, the ball mill and the 160-mesh high-frequency fine sieve form a closed loop, and the ...

Embodiment 3

[0026] A quartz glass powder, characterized in that: (1) select quartz ore with silica grade ≥95% and an average diameter of 2-5 mm after crushing, and first use a color sorter to remove impurities to make the silica grade in the quartz powder. The increase is greater than 99.5%; (2) the finished product of color separation enters a ball mill for wet ball milling, and the pulp is composed of quartz powder and an aqueous solution in a mass ratio of 4:1, and the aqueous solution contains 2 mass % of anionic surfactant and 2 mass % of silicon Sodium, the pH of the aqueous solution is 12, the ball milling concentration is 40% by mass, the ball mill rotation speed is 150 rpm, and the ball milling time is 2 hours. 10%, 30mm balls account for 50%, and 20mm balls account for 40%. The ball mill and 160-mesh high-frequency fine screen form a closed circuit, and products with unqualified fineness are returned to the ball mill for regrinding; The content is 50-60% by mass. (3) After ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com