High-liquidity starch and preparation method and application thereof

A high-fluidity, starch-based technology, applied in the field of high-fluidity starch and its preparation, can solve problems affecting the coating effect, achieve low production costs, shorten reaction time, and avoid gelatinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Use 75kg of water to prepare 25kg of dry base common corn starch into starch milk with a concentration of 25% by mass, add sodium sulfate equivalent to 3% (0.75kg) of starch dry base by mass, and pump the starch milk into the pipeline , circulating between the pipeline and the reaction tank, the pipeline is equipped with a clamp-type ultrasonic generator (manufactured by Guangzhou Xindongli Ultrasonic Electronic Equipment Co., Ltd., NPFS type), at an ultrasonic frequency of 15KHz, the ultrasonic intensity is 0.01W / cm 3 Under the effect on the subsequent reaction process of starch, the temperature of the starch slurry is controlled at 40°C by the jacketed water bath circulation in the reaction tank, and the pH value is adjusted to 9.0 with a 3% sodium hydroxide solution by mass percentage, and the pH value is adjusted to 9.0 at a rate of 10 ml / min. Slowly add chloroacetic acid equivalent to 0.5% (0.125kg) of starch on a dry basis for reaction, and keep the pH of the s...

Embodiment 2

[0044](1) Use 70kg of water to prepare 30kg of dry base tapioca starch into starch milk with a concentration of 30% by mass, add sodium sulfate equivalent to 5% (1.5kg) of starch dry base by mass, and pump the starch milk into the pipeline, Circulating between the pipeline and the reaction tank, the pipeline is equipped with a clamp-type ultrasonic generator (manufactured by Guangzhou Xindongli Ultrasonic Electronic Equipment Co., Ltd., NPFS type), at an ultrasonic frequency of 20KHz, the ultrasonic intensity is 0.05W / cm 3 Under the action of the subsequent reaction process of the starch, the temperature of the starch slurry is controlled to be 45°C through the jacketed water bath circulation in the reaction tank, and the pH value is adjusted to 9.5 with a 3% sodium hydroxide solution by mass percentage, and the pH value is adjusted to 9.5 at a rate of 10 ml / min. Slowly add chloroacetic acid (0.24kg) equivalent to 0.8% dry basis of starch for reaction, and keep the pH of starch...

Embodiment 3

[0049] (1) Use 65kg of water to prepare 35kg of dry wheat starch into starch milk with a concentration of 35% by mass, add sodium sulfate (3.5kg) equivalent to 10% by mass of starch dry basis, and pump the starch milk into the pipeline. Circulating between the pipeline and the reaction tank, the pipeline is equipped with a clamp-type ultrasonic generator (manufactured by Guangzhou Xindongli Ultrasonic Electronic Equipment Co., Ltd., NPFS type), at an ultrasonic frequency of 25KHz, the ultrasonic intensity is 0.1W / cm 3 Under the action of the subsequent reaction process of the starch, the temperature of the starch slurry is controlled at 50°C by the jacketed water bath circulation in the reaction tank, and the pH value is adjusted to 10.0 with a 3% sodium hydroxide solution by mass percentage, and the pH value is adjusted to 10.0 at a rate of 10 ml / min. Slowly add chloroacetic acid (0.35kg) which is equivalent to 1% of the dry weight of starch to react, and keep the pH of the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

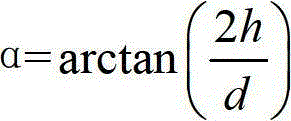

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com