Preparation method of compound potassium fulvate

A kind of technology of potassium fulvate and compound type, which is applied in the field of preparation of compound type potassium fulvate, can solve the problems such as poor persistence and weak effect of biochemical potassium fulvate, and achieve cost reduction, good acid adjustment and improvement Soil, the effect of huge application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

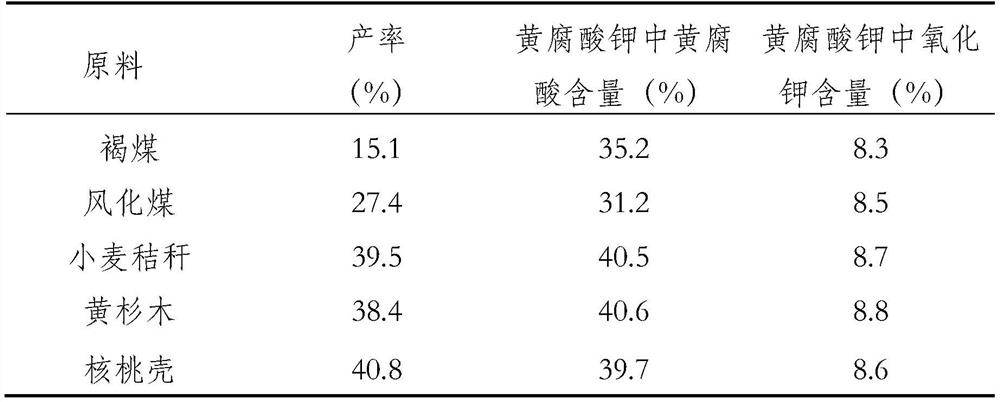

[0032] Use different low-priced coal or agricultural and forestry wastes on a dry basis as raw materials, with a mass fraction of 10% HNO 3 Experiment for an oxidizing agent:

[0033] Raw materials and thermal oxidation treatment: according to the solid-to-liquid ratio of 1:20, 10% HNO 3 Add it into a 50mL Erlenmeyer flask, and add the raw materials when it is preheated to 70°C. The ratio of the raw materials is shown in Table 1. The reaction was carried out for 60 min under the conditions of water bath temperature 70° C. and shaking speed 150 rpm.

[0034] Extraction: After the reactant is cooled to room temperature, carry out vacuum filtration to obtain HNO 3 The thermal oxidation residue was washed with water until neutral, and the filtrate was kept, and the upper layer residue was further prepared into potassium fulvic acid.

[0035] Drying: Pour the filtrate into a beaker and dry it in a blast drying oven at 60°C to obtain potassium fulvic acid solids.

[0036] Table ...

Embodiment 2

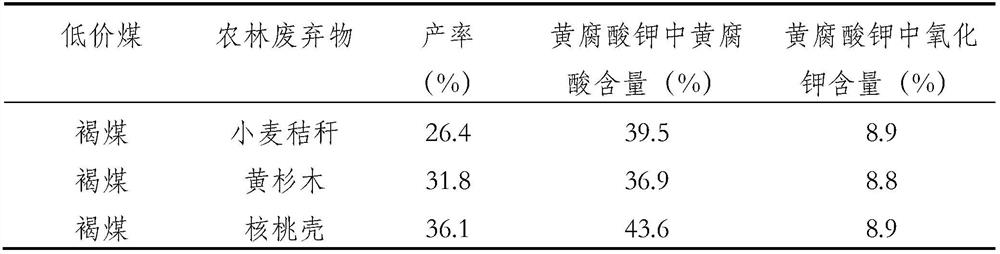

[0039] Using different low-priced coal and agricultural and forestry waste mixtures with a mass ratio of 1:1 on a dry basis as raw materials, HNO with a mass fraction of 10% 3 Experiment for an oxidizing agent:

[0040] Raw materials and thermal oxidation treatment: according to the solid-to-liquid ratio of 1:20, 10% HNO 3 Put it into the Erlenmeyer flask, and add the mixed raw materials when it is preheated to 70°C. The types of mixed raw materials are shown in Table 2. The reaction was carried out for 60 minutes under the conditions of water bath temperature 70° C. and shaking speed 150 rpm.

[0041] Extraction: After the reactant is cooled to room temperature, carry out vacuum filtration to obtain HNO 3 The thermal oxidation residue was washed with water until neutral, and the filtrate was kept, and the upper layer residue was further prepared into potassium fulvic acid.

[0042] Drying: Pour the filtrate into a beaker and dry it in a blast drying oven at 60°C to obtain ...

Embodiment 3

[0047] With different mass ratios of weathered coal and walnut shells as raw materials, the mass fraction of 10% H 2 SO 4 Oxidizing agent for experiment:

[0048] Raw materials and thermal oxidation treatment: according to the solid-to-liquid ratio of 1:20, first add 10% H 2 SO 4 Add it to the Erlenmeyer flask, and add the raw materials when it is preheated to 80°C. The reaction was carried out for 90 min at a water bath temperature of 90° C. and a shaking rate of 200 rpm.

[0049] Extraction: After the reactant is cooled to room temperature, carry out vacuum filtration to obtain H 2 SO 4 The thermal oxidation residue was washed with water until neutral, and the filtrate was kept, and the upper layer residue was further prepared into potassium fulvic acid.

[0050] Drying: Pour the filtrate into a beaker and dry it in a blast drying oven at 60°C to obtain potassium fulvic acid solids. Table 3 shows the content of fulvic acid in the compound potassium fulvate prepared by d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com