Compact range device based on microstrip patch reflective array antenna

A reflect array antenna, microstrip patch technology, applied to antennas, measuring devices, antenna arrays, etc., can solve the problems of high processing cost, difficult lens material processing, increasing paraboloid size, etc., and achieve manufacturing costs and maintenance costs. Low, improve the quality of plane wave quiet zone, the effect of mature and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

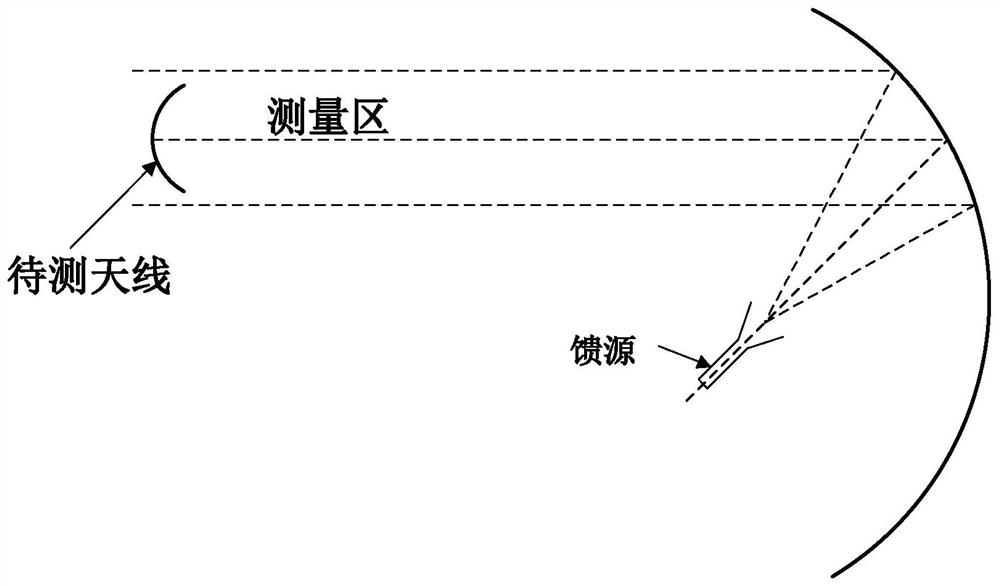

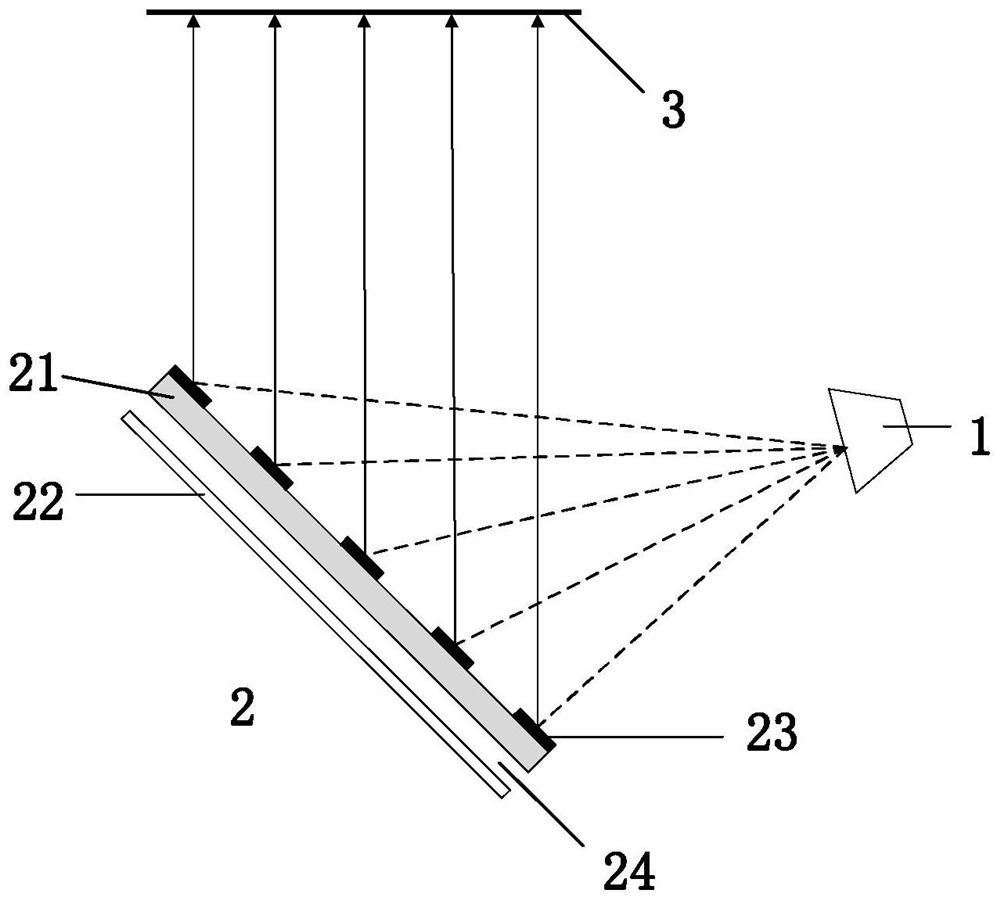

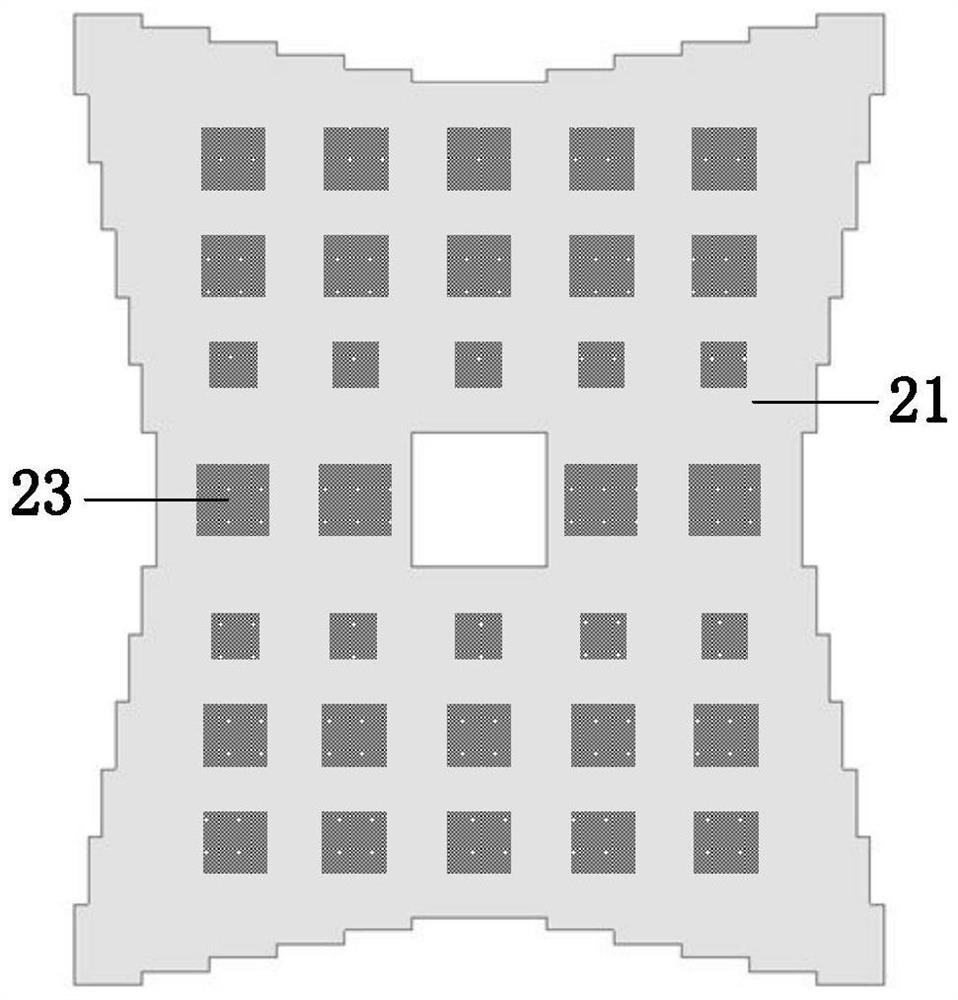

[0037] refer to image 3 In the system structure shown, the feed source is a pyramid horn, and the feed method adopts a bias feed; the center frequency of the microstrip patch reflectarray antenna is set to 10GHz, the unit interval is one-third wavelength, and the focal-to-diameter ratio F / D is 1.8, and the edge of the dielectric plate of the microstrip patch reflectarray antenna is processed in a step-like manner, and the center of the dielectric plate is set as an empty area to reduce the number of patch units of the reflector and optimize the exit field quiet zone.

[0038] 2. Simulation content:

[0039] In the above example, the spherical wave irradiated by the feed source is converted into a plane wave by the microstrip patch reflectarray antenna, and the phases of the reflectarray units with different side lengths corresponding to different air layer thicknesses are simulated to obtain the phase shift curves of the reflector units, such as Image 6 shown. Depend on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com