Lightweight thermal-insulation aerated building block and preparation method thereof

An aerated block and thermal insulation technology, applied in the field of building materials, can solve the problems of low compressive strength, weak bubble binding force, small cell diameter and small cell diameter, etc., to achieve strong overall bearing capacity, improve compressive strength, The effect of evenly distributed air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation method of a light-weight thermal insulation aerated block, comprising the following steps:

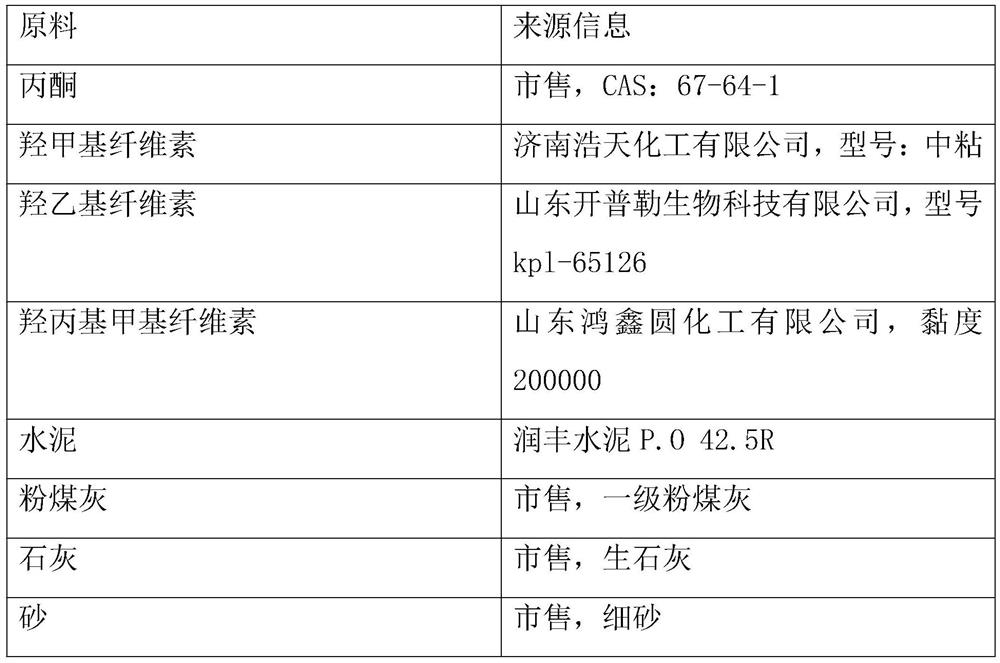

[0053] Step 1), put 100kg of water, 3kg of thickening agent, and 0.5kg of acetone into the stirring tank, rotate at 60r / min, stir for 1min, and mix well to obtain an acetone solution.

[0054] Step 2), put 43kg of cement, 94kg of fly ash, 132kg of lime, and 1150kg of sand into the acetone solution, the rotating speed is 45r / min, stirred for 3min, and mixed evenly to obtain a mixing material.

[0055] Step 3), pouring the mixture into the mold, tamping, and discharging air bubbles to form an embryo body.

[0056] Step 4), sending the embryo body into the steaming equipment, heating and steaming, the steaming temperature is 48°C, the steaming pressure is 0.3MPa, and the steaming is 130min.

[0057] In step 5), the steam curing temperature was raised to 54.5° C., the steam curing pressure was 0.5 MPa, and the steam curing was performed for 85 min.

[0058]In step 6)...

Embodiment 2

[0062] A preparation method of a light-weight thermal insulation aerated block, comprising the following steps:

[0063] Step 1), put 100kg of water, 4kg of thickening agent, and 0.55kg of acetone into the stirring tank, rotate at 60r / min, stir for 1min, and mix well to obtain an acetone solution.

[0064] Step 2), put 44kg cement, 97kg fly ash, 136kg lime, 1165kg sand into the acetone solution, rotate speed 45r / min, stir for 3min, and mix well to obtain a mixing material.

[0065] Step 3), pouring the mixture into the mold, tamping, and discharging air bubbles to form an embryo body.

[0066] Step 4), sending the embryo body into the steaming equipment, heating and steaming, the steaming temperature is 48.5°C, the steaming pressure is 0.35MPa, and the steaming is 125min.

[0067] Step 5), the steam curing temperature was raised to 54.8° C., the steam curing pressure was 0.55 MPa, and the steam curing was performed for 83 min.

[0068] In step 6), the steam curing temperatur...

Embodiment 3

[0072] A preparation method of a light-weight thermal insulation aerated block, comprising the following steps:

[0073] Step 1), put 100kg of water, 5kg of thickening agent, and 0.6kg of acetone into the stirring tank, rotate at 60r / min, stir for 1min, and mix well to obtain an acetone solution.

[0074] Step 2), put 45kg of cement, 100kg of fly ash, 140kg of lime, and 1180kg of sand into the acetone solution, rotate at 45r / min, stir for 3min, and mix evenly to obtain a mixing material.

[0075] Step 3), pouring the mixture into the mold, tamping, and discharging air bubbles to form an embryo body.

[0076] Step 4), sending the embryo body into the steaming equipment, heating and steaming, the steaming temperature is 49°C, the steaming pressure is 0.4MPa, and the steaming is 120min.

[0077] Step 5), the steam curing temperature was raised to 55°C, the steam curing pressure was 0.6 MPa, and the steam curing was performed for 80 min.

[0078] Step 6), the steam curing temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com