Coating capable of removing formaldehyde and preparation method thereof

A technology for eliminating formaldehyde and coatings, applied in the field of coatings, can solve problems such as unstable removal of formaldehyde, achieve excellent mechanical properties, improve adsorption and capture efficiency, and good film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

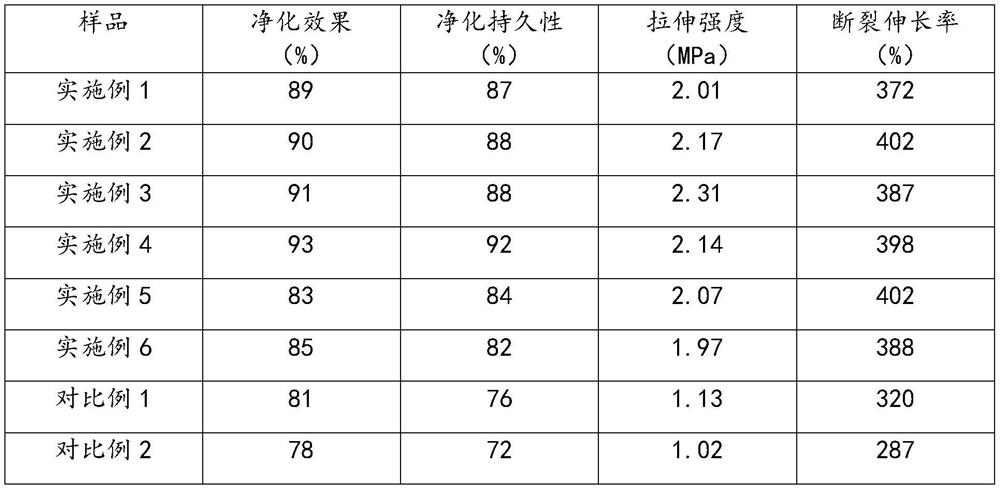

Examples

Embodiment 1

[0020] This embodiment provides a paint that can eliminate formaldehyde, and the paint includes the following parts by weight: 100 parts of water, 75 parts of acrylic emulsion, 28 parts of nano-barium sulfate, 8 parts of nano-scale zinc oxide, and modified multi-wall carbon 4 parts of nanotubes, 12 parts of alcohol esters, 2 parts of sodium lauryl sulfate, 0.6 parts of polydimethylsiloxane;

[0021] Described preparation method that can eliminate formaldehyde, specifically comprises the steps:

[0022] (1) Modification of multi-walled carbon nanotubes: 10 g of multi-walled carbon nanotubes were added to a mixed solution of 1 L of sulfuric acid and nitric acid (sulfuric acid: nitric acid=3:1, volume ratio), and the filtrate was filtered after 3 hours of ultrasonic vibration reaction. After washing and drying with 10L of deionized water, carboxyl-functionalized multi-walled carbon nanotubes (MWNTs-COOH) were obtained, then the obtained multi-walled carbon nanotubes were added to...

Embodiment 2

[0027] This embodiment provides a paint that can eliminate formaldehyde. The paint comprises the following parts by weight: 100 parts of water, 80 parts of acrylic emulsion, 30 parts of nano-barium sulfate, 8 parts of nano-scale zinc oxide, and modified multi-wall carbon 5 parts of nanotubes, 1 part of propylene glycol, 2 parts of sodium lauryl sulfate, 0.6 part of polydimethylsiloxane;

[0028] The preparation method of this example is the same as that of Example 1.

Embodiment 3

[0030] This embodiment provides a paint that can eliminate formaldehyde, and the paint includes the following components by weight: 100 parts of water, 90 parts of acrylic emulsion, 30 parts of nano-barium sulfate, 10 parts of nano-scale zinc oxide, and modified multi-wall carbon 7 parts of nanotubes, 2 parts of propylene glycol butyl ether, 2 parts of sodium lauryl sulfate, 0.6 parts of polydimethylsiloxane;

[0031] The preparation method of this example is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com