Tight coupling diesel engine exhaust aftertreatment system and method

An exhaust aftertreatment, diesel engine technology, applied in exhaust treatment, electronic control of exhaust treatment device, diagnosis device of exhaust treatment device, etc. Large, difficult to arrange the chassis and other problems, to avoid impact, reasonable installation and efficient matching, small package size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with reference to the specific embodiments in the accompanying drawings.

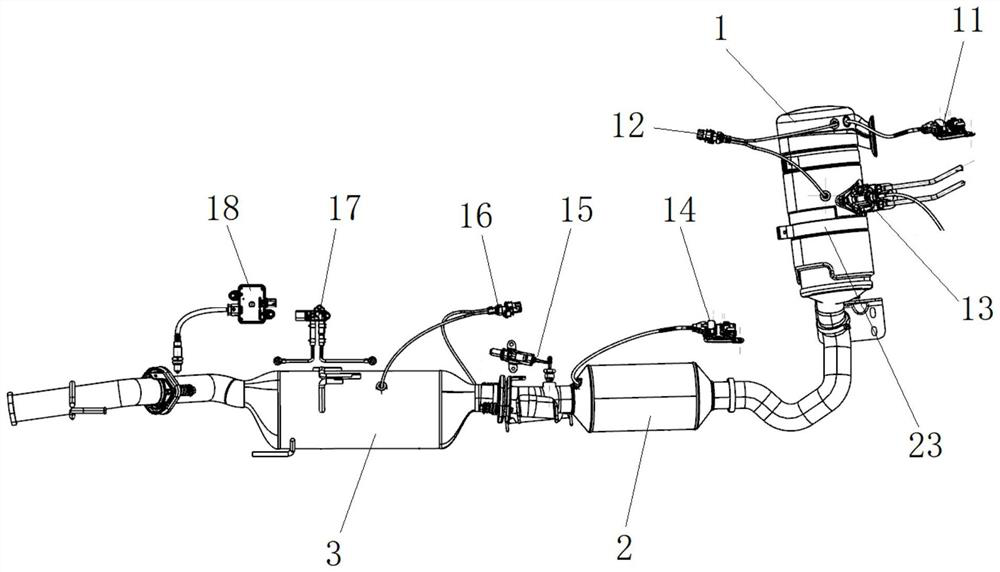

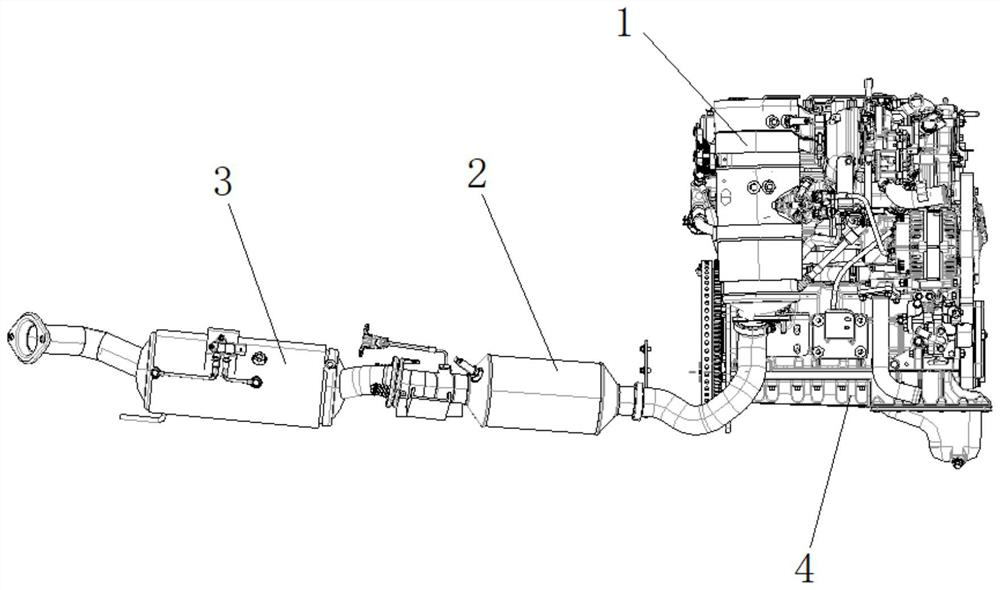

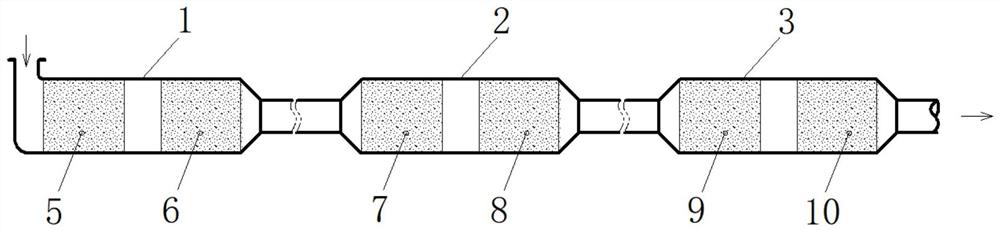

[0038] see Figure 1-6 , a tightly coupled diesel engine exhaust aftertreatment system of the present invention includes a first-level after-treatment unit 1, a second-level after-treatment unit 2 and a third-level after-treatment unit 3, wherein the first-level after-treatment unit 1 is coupled and installed in the diesel engine 4, that is, the exhaust inlet of the primary post-processing unit 1 is directly coupled to the exhaust outlet of the turbocharger of the diesel engine 4, and the primary post-processing unit 1, the secondary post-processing unit 2 and the tertiary post-processing unit Units 3 are connected in sequence. Specifically, the three are connected through a gas pipe, and the gas pipe and the three post-processing units are connected by a flange, which is convenient for disassembly and assembly. The diesel engine exhaust flows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com