NO oxidation catalyst for removing NOx in ship and preparation method of NO oxidation catalyst

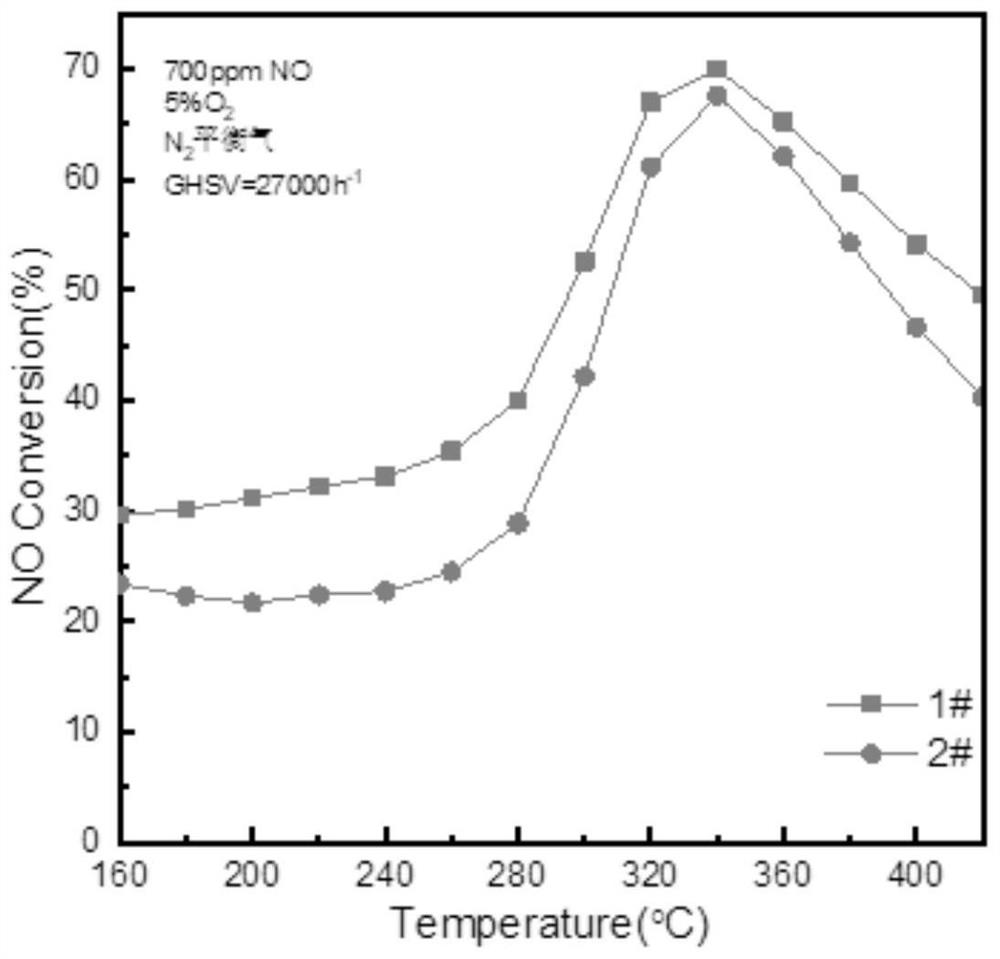

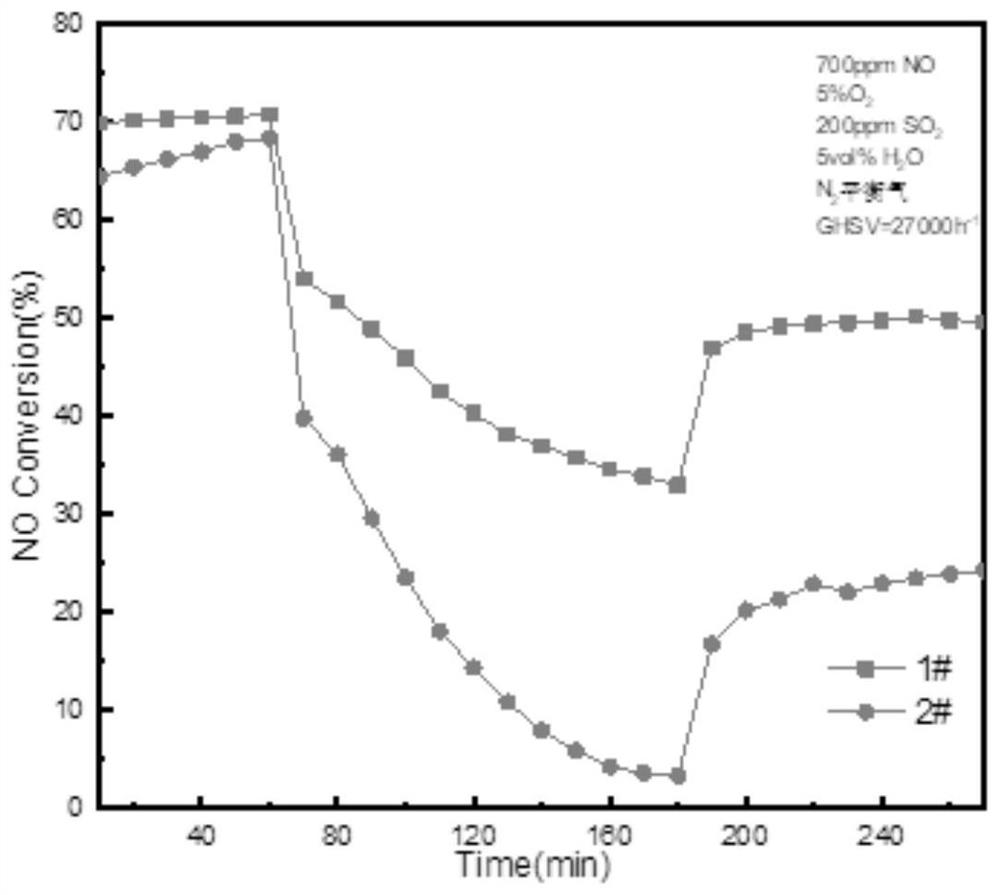

A technology of oxidation catalyst and deionized water, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. It can solve the problem of large footprint and high quality of SCR catalyst. problem, to achieve the effect of small footprint, solve the problem of insufficient layout space, and good high temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Accurately weigh Ce(NO) with a mass of 12.6 g 3 ) 3 ·6H 2 O powder and 8.1 g of Zr (NO 3 ) 4 ·5H 2 O powder, dissolve in a certain amount of deionized water and mix well. The above solution was placed in an ultrasonic device and stirred, heated in a water bath at 70°C until transparent, and then 1 mol / L sodium hydroxide solution was added until the pH value was 12-13 to obtain a precipitated viscous substance and continued stirring for 2 hours, and then 7.5 g of sodium hydroxide solution was added. γ-Al 2 O 3 powder, continue to stir for 2h, and the obtained viscous substance is placed in a ceramic suction filtration device and washed to neutrality. The obtained neutral substance was oven-dried, calcined in a muffle furnace at 600° C. for 3 hours, and ground to powder to obtain the target catalyst carrier powder. Put 29.2ml of RuCl 3 ·6H 2 O (4g / L) solution, dissolved in a certain amount of deionized water, then added the prepared carrier powder, stirred and m...

Embodiment 2

[0027] Accurately weigh Ce(NO) with a mass of 12.6 g 3 ) 3 ·6H 2 O powder, 8.1 g of Zr (NO 3 ) 4 ·5H 2 O powder and 7.5 g of γ-Al 2 O 3 Powder, dissolve in a certain amount of deionized water and mix well. The above solution was placed in an ultrasonic device and stirred, heated in a water bath at 70°C, and then 1 mol / L sodium hydroxide solution was added to adjust the pH to 12-13 to obtain a precipitated viscous substance and continue stirring for 2 hours. The ceramic suction filtration device is washed to neutrality. The obtained neutral substance was oven-dried, calcined in a muffle furnace at 600° C. for 3 hours, and ground to powder to obtain the target catalyst carrier powder. Put 29.2ml of RuCl 3 ·6H 2 O (4g / L) solution, dissolved in a certain amount of deionized water, then added the prepared carrier powder, stirred and mixed in an ultrasonic device, heated in a water bath at 70°C, stirred for 3h, and moved to an oven to dry at 550 ℃ temperature muffle furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com