Automatic gluing equipment for composite boards

A composite wood board and gluing technology, which is applied in the direction of coating, glue container, wood processing equipment, etc., can solve the problems that wood boards of different specifications cannot be fixed, affect the firmness of gluing, and affect the curing speed, etc., so as to simplify the structure and improve processing Efficiency, friction-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

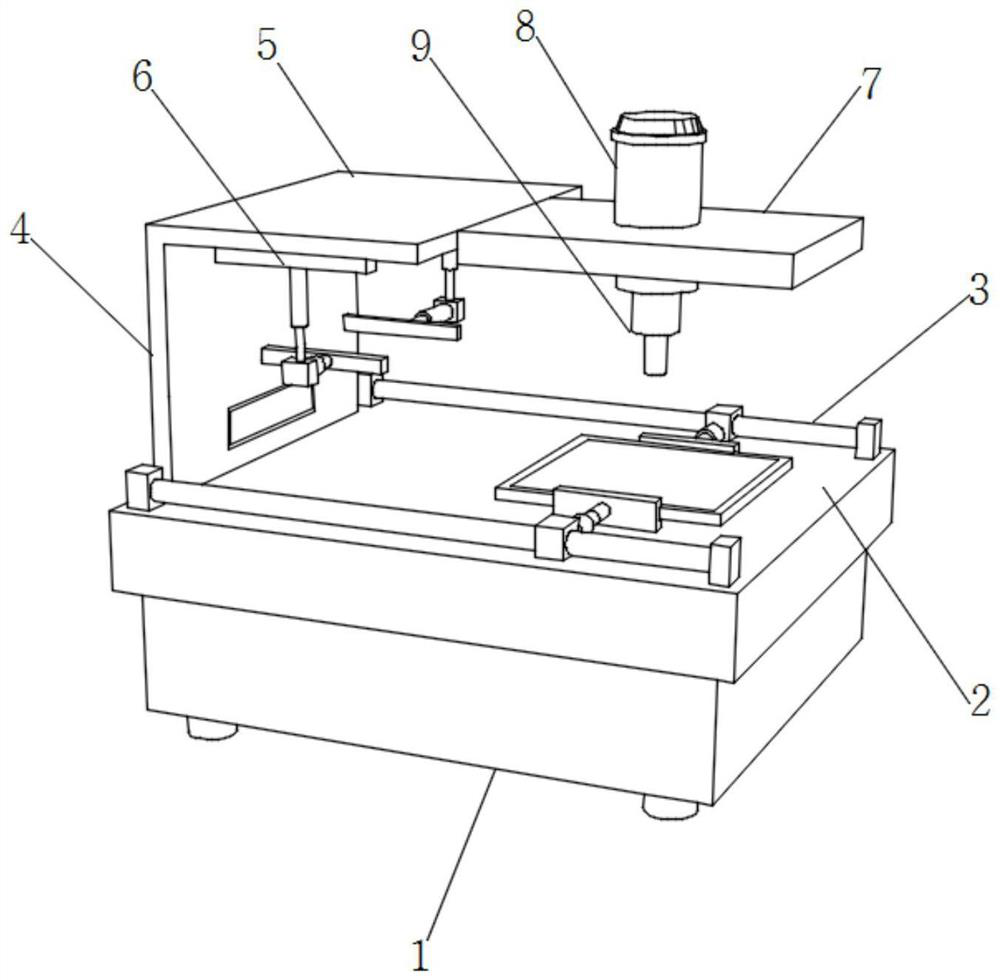

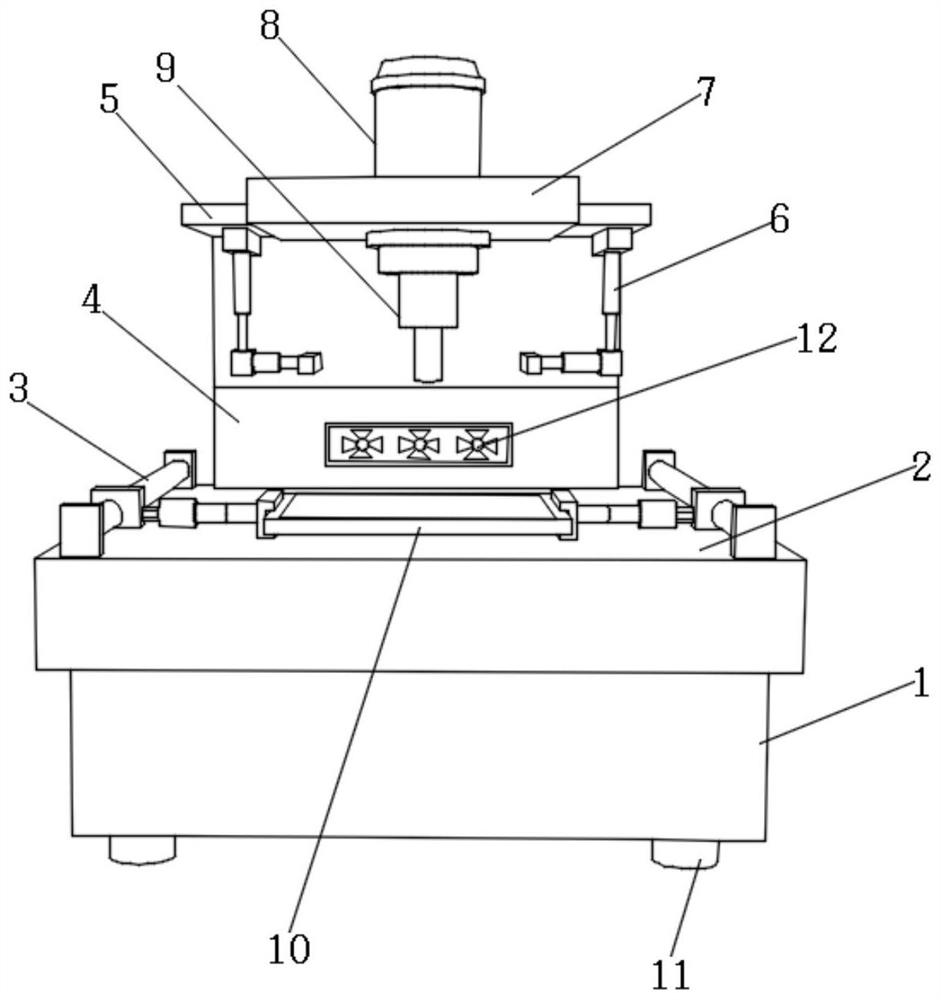

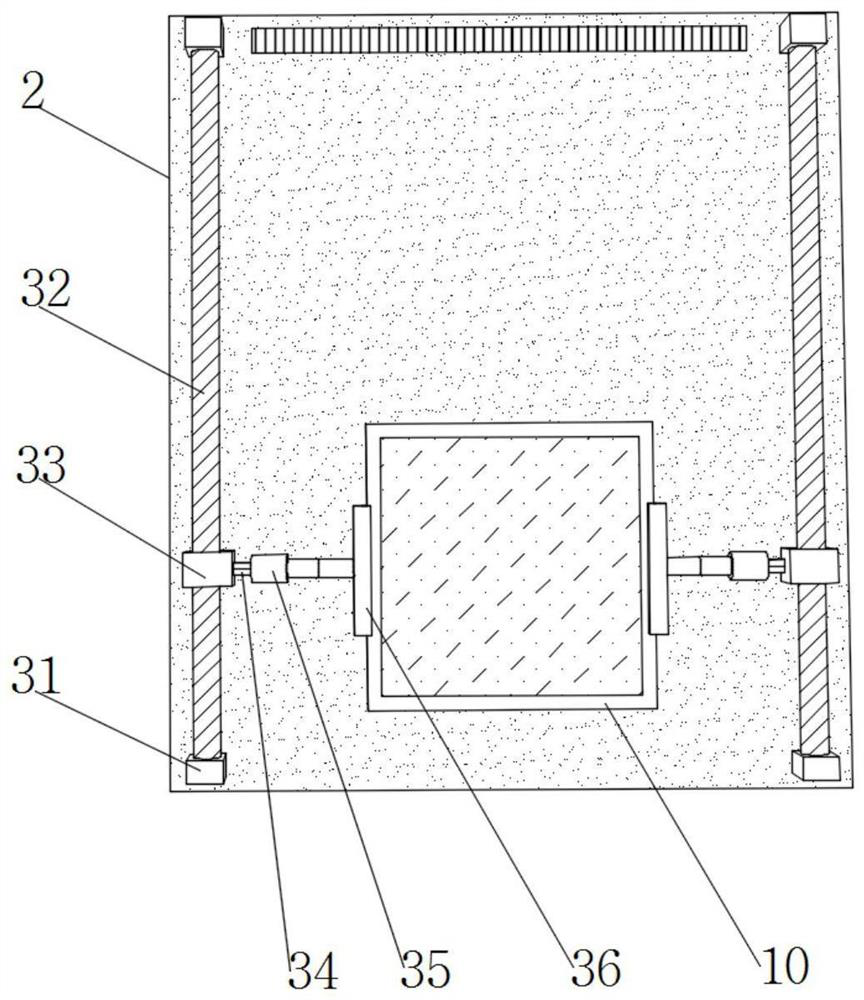

[0039] like Figure 1-7 As shown, the present invention provides an automatic gluing equipment for composite wood boards, including a base 1, a workbench 2 is arranged on the upper part of the base 1, a glue coating assembly 3 is arranged on the upper part of the workbench 2, and the upper part of the workbench 2 is left on the left side. A supporting vertical plate 4 is fixedly installed on the side, a first supporting horizontal plate 5 is fixedly installed on the upper part of the supporting vertical plate 4, a wood gluing assembly 6 is arranged at the bottom of the first supporting horizontal plate 5, and the gluing assembly 3 includes an electric sliding rod 32, an electric An electric slider 33 is movably installed on the outside of the sliding rod 32, and the wood board gluing assembly 6 includes a vertical electric telescopic rod 62. The lower part of the vertical electric telescopic rod 62 is fixedly installed with a receiving block 63, and the side of the receiving bl...

Embodiment 2

[0044] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the limiting component 36 includes a limiting pressing plate 361, and the left side of the limiting pressing plate 361 is fixedly mounted with a first arc-shaped elastic sheet 362 , the left side of the first arc-shaped elastic sheet 362 is fixedly installed with a second arc-shaped elastic sheet 363, and the right side of the second arc-shaped elastic sheet 363 and the left side of the first arc-shaped elastic sheet 362 are provided with elastic balls 364, away from The outer side of the elastic ball 364 is provided with a buffer column 365 .

[0045] The limiting components 36 are arranged to be two corresponding to the left and right sides of the wooden panel 10 respectively, and the corresponding hydraulic rods 35, connecting rods 34 and electric sliding rods 32 are all two, and they are all activated at the same time when in use. At the same ti...

Embodiment 3

[0049] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the right side of the clamping assembly 65 is fixedly installed with the wood board extrusion layer 66, and the outer surface of the wood board extrusion layer 66 is fixedly installed with elastic protrusions From 67 , a pressing elastic block 661 is provided inside the wood board pressing layer 66 .

[0050] The limiting components 36 are arranged to correspond to the left and right sides of the wooden panel 10 respectively, and the corresponding hydraulic rods 35, connecting rods 34 and electric sliding rods 32 are all two. The components 6 are arranged in two groups, corresponding to the left and right sides of the wooden board respectively. When the wooden board is fixed, the friction force of the wooden board is increased by setting the elastic protrusions 67, so that the wooden board can be prevented from falling off when it is clamped, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com