Composite film with high sealing property and strong heat resistance

A composite film, high-sealing technology, used in synthetic resin layered products, biological packaging, sustainable packaging, etc., to achieve high heat-sealing strength, high heat resistance, and a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

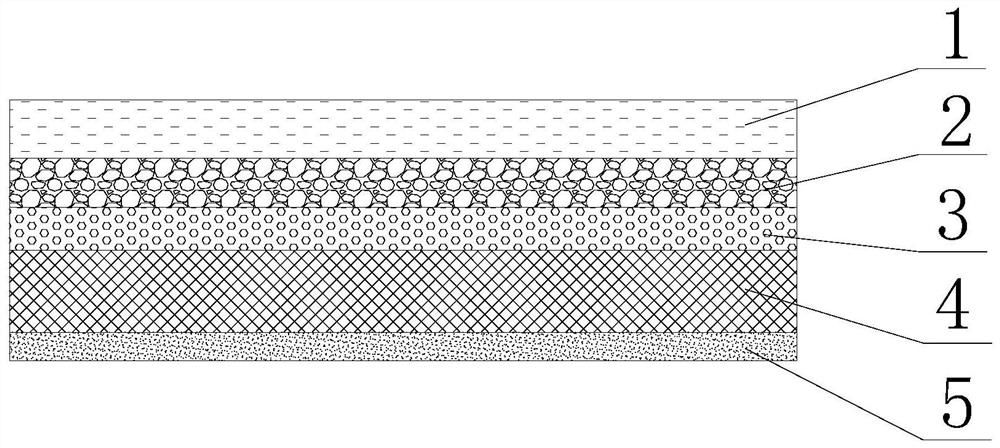

[0037] High sealing strength heat-resistant composite film, including thermoplastic resin film inner layer, core layer, heat-resistant film outer layer; thermoplastic resin film inner layer including heat-sealing layer, high-sealing protective layer; heat-sealing layer made of EVA hot melt adhesive The high-sealing protective layer is made of polyethylene;

[0038] The core layer includes an anti-oxidant layer and a reinforcing layer. The anti-oxidation layer is located on the high-sealing protective layer, and the reinforcing layer is located on the anti-oxidizing layer; the anti-oxidizing layer is made of nylon material with antioxidant added, and the reinforcing layer is nylon with glass fiber material; the nylon material is made of homopolymerization and copolymerization blending, the relative viscosity is 3-3.5, and the density is 1.12-1.15g / cm 3 .

[0039] The outer layer of the heat-resistant film is made of nylon 6 composite material; the specific preparation steps of...

Embodiment 2

[0044] High sealing strength heat-resistant composite film, including thermoplastic resin film inner layer, core layer, heat-resistant film outer layer; thermoplastic resin film inner layer including heat-sealing layer, high-sealing protective layer; heat-sealing layer made of EVA hot melt adhesive The high-sealing protective layer is made of polyethylene;

[0045] The core layer includes an anti-oxidant layer and a reinforcing layer. The anti-oxidation layer is located on the high-sealing protective layer, and the reinforcing layer is located on the anti-oxidizing layer; the anti-oxidizing layer is made of nylon material with antioxidant added, and the reinforcing layer is nylon with glass fiber material; the nylon material is made of homopolymerization and copolymerization blending, the relative viscosity is 3-3.5, and the density is 1.12-1.15g / cm 3 .

[0046] The outer layer of the heat-resistant film is made of nylon 6 composite material; the specific preparation steps of...

Embodiment 3

[0051] High sealing strength heat-resistant composite film, including thermoplastic resin film inner layer, core layer, heat-resistant film outer layer; thermoplastic resin film inner layer including heat-sealing layer, high-sealing protective layer; heat-sealing layer made of EVA hot melt adhesive The high-sealing protective layer is made of polyethylene;

[0052] The core layer includes an anti-oxidant layer and a reinforcing layer. The anti-oxidation layer is located on the high-sealing protective layer, and the reinforcing layer is located on the anti-oxidizing layer; the anti-oxidizing layer is made of nylon material with antioxidant added, and the reinforcing layer is nylon with glass fiber material; the nylon material is made of homopolymerization and copolymerization blending, the relative viscosity is 3-3.5, and the density is 1.12-1.15g / cm 3 .

[0053] The outer layer of the heat-resistant film is made of nylon 6 composite material; the specific preparation steps of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com