Method for deeply purifying and purifying calcium sulfate dihydrate by using fine-particle ardealite

A calcium sulfate dihydrate, deep purification technology, applied in chemical instruments and methods, calcium/strontium/barium sulfate, inorganic chemistry, etc., can solve the problems of poor purification effect, high energy consumption, long time consumption, etc., and achieve purification efficiency High, good treatment effect, good impurity removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

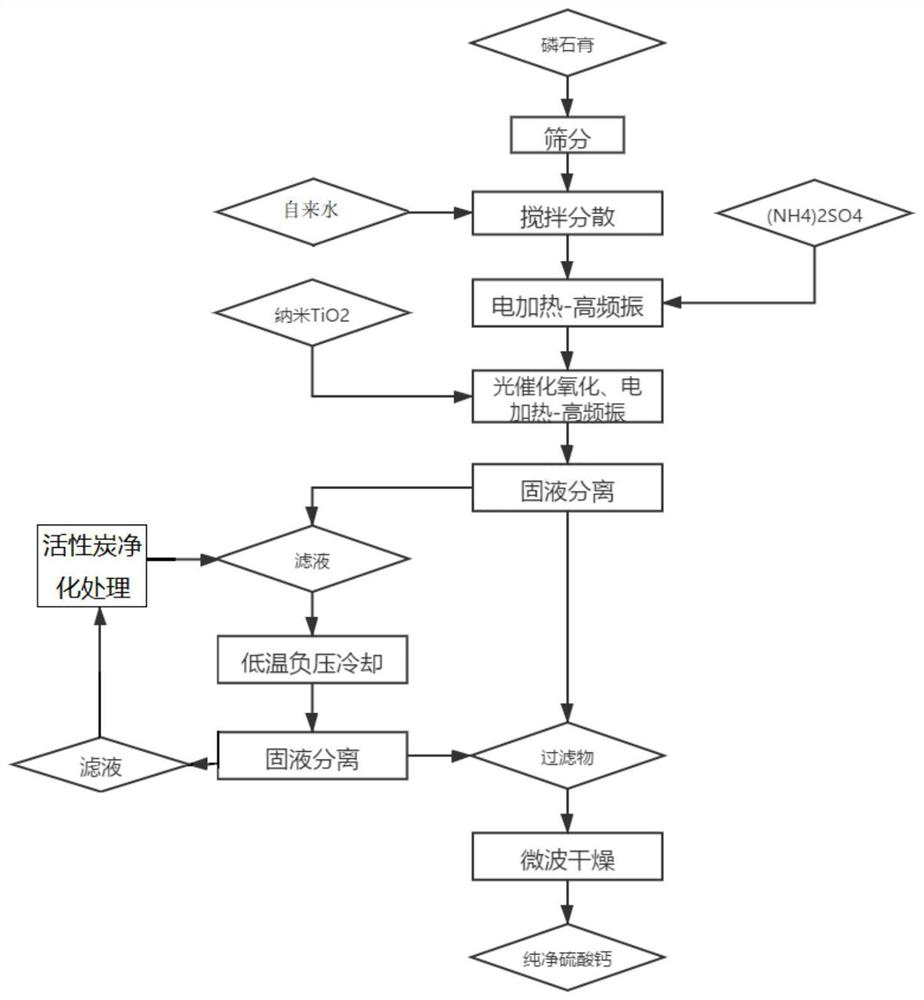

Image

Examples

Embodiment 1

[0028] (1) sieving the phosphogypsum particles, and collecting fine-grained phosphogypsum with a particle size of less than 80 μm;

[0029] (2) according to the mass ratio of water and fine-grained phosphogypsum to be 3:1, add water in the fine-grained phosphogypsum of step (1), and fully stir to obtain slurry;

[0030] (3) Press (NH 4 ) 2 SO 4 : the slurry is a solid-liquid ratio of 5g / L, and (NH) is added to the slurry in step (2). 4 ) 2 SO 4 , turn on high-frequency vibration and electric heating, so that the slurry maintains high-frequency vibration at 80 °C, and the frequency of high-frequency vibration is 100KHz;

[0031] (4) After maintaining the high-frequency vibration for 30min, according to the dosage of 200mg / L, put nano-TiO into the slurry obtained in step (3). 2 ;

[0032] (5) maintaining high-frequency vibration, and using an ultraviolet light source with a power of 80W and a wavelength of 365nm to irradiate the slurry for 30min, so that a photocatalytic ...

Embodiment 2

[0038] (1) sieving the phosphogypsum particles, and collecting fine-grained phosphogypsum with a particle size of less than 80 μm;

[0039] (2) according to the mass ratio of water and fine-grained phosphogypsum to be 2:1, add water in the fine-grained phosphogypsum of step (1), and fully stir to obtain slurry;

[0040] (3) Press (NH 4 ) 2 SO 4 : the slurry is a solid-liquid ratio of 6g / L, and (NH) is added to the slurry in step (2). 4 ) 2 SO 4 , turn on high-frequency vibration and electric heating, so that the slurry maintains high-frequency vibration at 95 °C, and the frequency of high-frequency vibration is 50KHz;

[0041] (4) After maintaining the high-frequency vibration for 25min, according to the dosage of 180mg / L, put nano-TiO into the slurry obtained in step (3). 2 ;

[0042] (5) maintain high-frequency vibration, and use an ultraviolet light source with a power of 100W and a wavelength of 365nm to irradiate the slurry for 25min, so that a photocatalytic oxida...

Embodiment 3

[0048] (1) sieving the phosphogypsum particles, and collecting fine-grained phosphogypsum with a particle size of less than 80 μm;

[0049] (2) according to the mass ratio of water and fine-grained phosphogypsum to be 5:1, add water in the fine-grained phosphogypsum of step (1), and fully stir to obtain slurry;

[0050] (3) Press (NH 4 ) 2 SO 4 : the slurry is a solid-liquid ratio of 4g / L, and (NH) is added to the slurry in step (2). 4 ) 2 SO 4 , turn on high-frequency vibration and electric heating, so that the slurry maintains high-frequency vibration at 90 ℃, and the frequency of high-frequency vibration is 200KHz;

[0051] (4) After maintaining the high-frequency vibration for 40min, according to the dosage of 100mg / L, put nano-TiO into the slurry obtained in step (3). 2 ;

[0052] (5) maintain high-frequency vibration, and use an ultraviolet light source with a power of 90W and a wavelength of 365nm to irradiate the slurry for 40min, so that a photocatalytic oxidat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com