Method for catalyzing alcoholysis of waste PET ethylene glycol by heteroatom-doped zinc oxide

A zinc oxide and heteroatom technology, applied in the fields of polymer degradation, green catalysis technology and plastics, can solve the problems of poor product selectivity and low yield, and achieve the effects of high selectivity, low cost, and easy separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

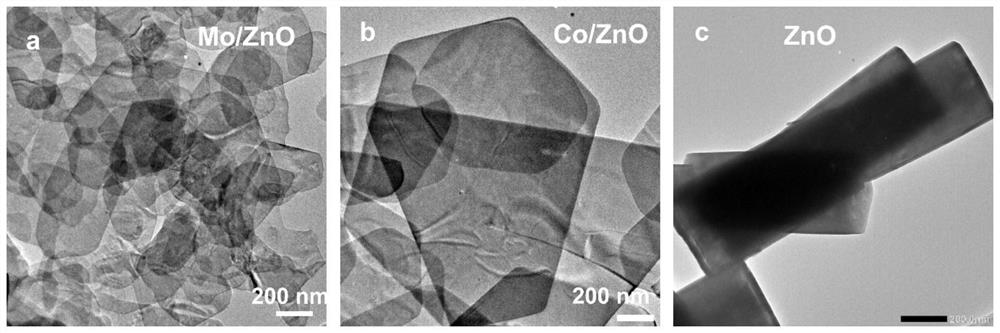

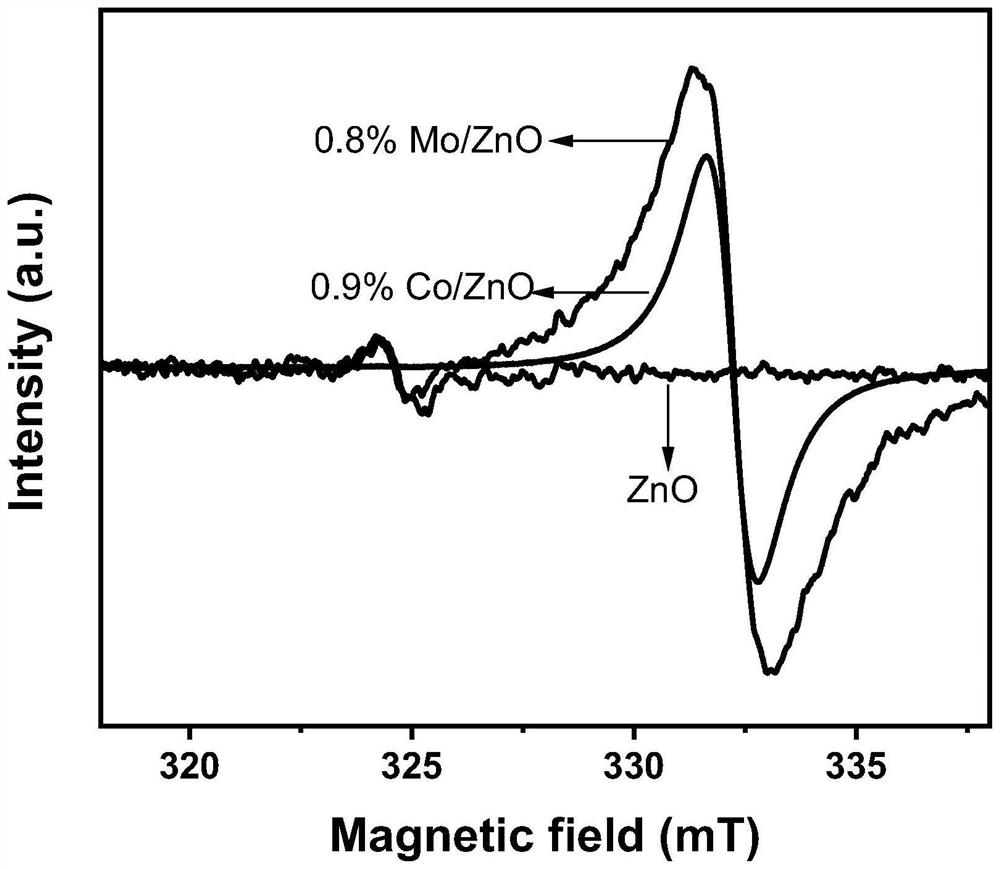

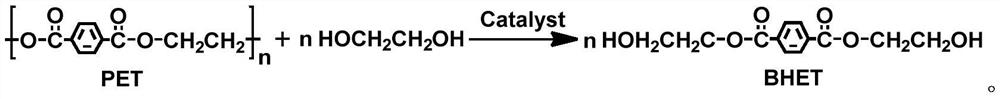

[0031] The waste PET, its mass 1% Co / ZnO, Mo / ZnO, ZnO and its mass ratio of 4:1 ethylene glycol were put into a single-necked flask, heated to 180 °C, reacted for 1 h, and magnetically stirred. After the reaction, 400 mL of ultrapure water was added and stirred vigorously to prevent the precipitation of monomer crystals. Then collect the insoluble PET and oligomers and filtrate filtered by suction, and after the filtrate is adjusted to 1L, take an appropriate amount of solution for later use. After the reaction, the product BHET was analyzed by HPLC, and the yield of BHET and the conversion rate of PET were calculated. For the BHET yield and PET conversion data of different metal-doped ZnO catalysts for the glycolysis of waste PET, please refer to the serial numbers 1-4 in Table 1 for details.

[0032] Table 1 Effects of different metal-doped ZnO on the alcoholysis of waste PET catalyzed by glycol

[0033] Example catalyst PET conversion rate / % BHET yield / % ...

Embodiment 5-8

[0036] The waste PET and its catalyst Mo / ZnO (the mass ratio of Mo = 0.8-27.9 wt %) and its mass ratio of 4:1 were sequentially added to a 25 mL single-neck flask. After the temperature was raised to 180°C, the reaction was carried out for 1 h, and the mixture was magnetically stirred. After the reaction, 400 mL of ultrapure water was added and stirred vigorously to prevent the precipitation of monomer crystals. Then collect the insoluble PET and oligomers and filtrate filtered by suction, and after the filtrate is adjusted to 1L, take an appropriate amount of solution for later use. After the reaction, the product BHET was analyzed by HPLC, and the yield of BHET and the conversion rate of PET were calculated. The effect of Mo addition on the catalyzed alcoholysis of PET glycol by Mo / ZnO catalyst is shown in the serial numbers 5-8 in Table 2.

[0037] Table 2 Examples 5-8 Influence of Mo addition on Mo / ZnO catalyzed glycolysis of waste PET

[0038] Example Mo ma...

Embodiment 9-13

[0041] The waste PET, Mo / ZnO with a mass ratio of 0.1 to 5% and ethylene glycol with a mass ratio of 4:1 were put into a single-necked flask, and the temperature was raised to 180° C. and reacted for 60 min. After the reaction, the product BHET was analyzed by HPLC, and the yield of BHET and the conversion rate of PET were obtained by calculation, as shown in the serial numbers 9-13 in Table 3 for details.

[0042] Table 3 Influence of the amount of Mo / ZnO on the alcoholysis of waste PET with glycol

[0043] Example catalyst(%) PET conversion rate / % BHET yield / % 9 0.1 82.7 76.9 10 0.2 91.2 86.1 11 1 100 94.5 12 2 100 92.7 13 5 100 93.2

[0044] 4. Effects of different reaction temperatures on 0.8% Mo / ZnO catalyzed glycolysis of waste PET

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com