Preparation method and application of blended membrane based on microporous framework

A technology of blended membrane and framework, applied in the field of preparation of blended membrane based on microporous framework, can solve the problems of sacrificial material proton conductivity, hinder vanadium ion penetration, etc., to improve related properties, enhance vanadium resistance properties, and increase Coulombic efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

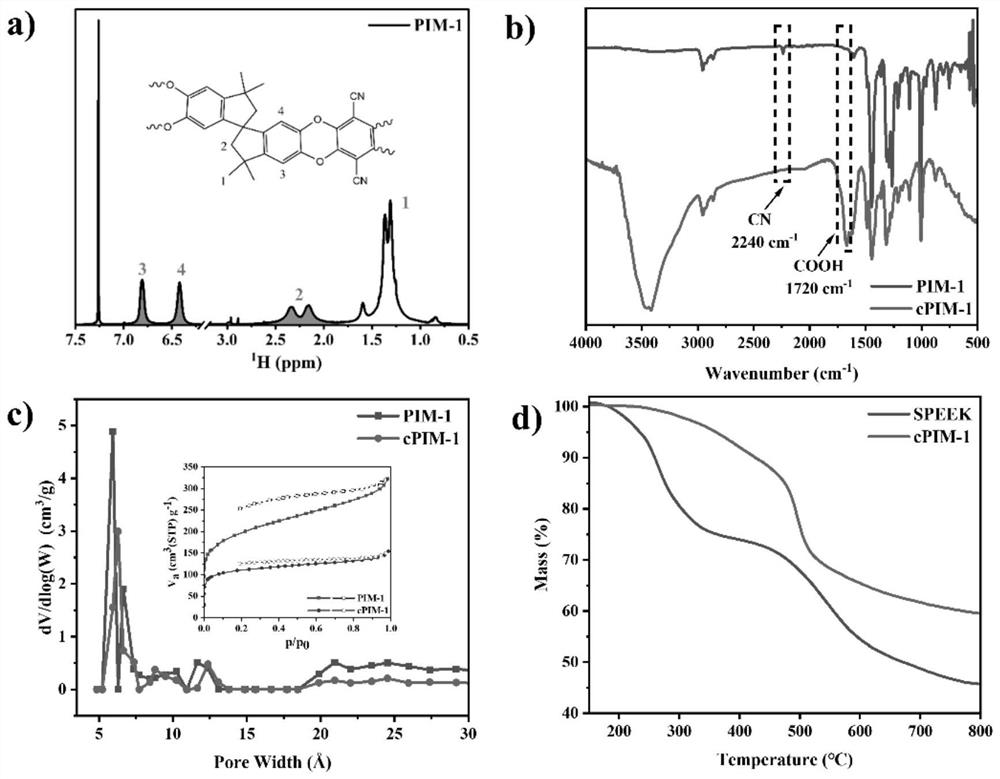

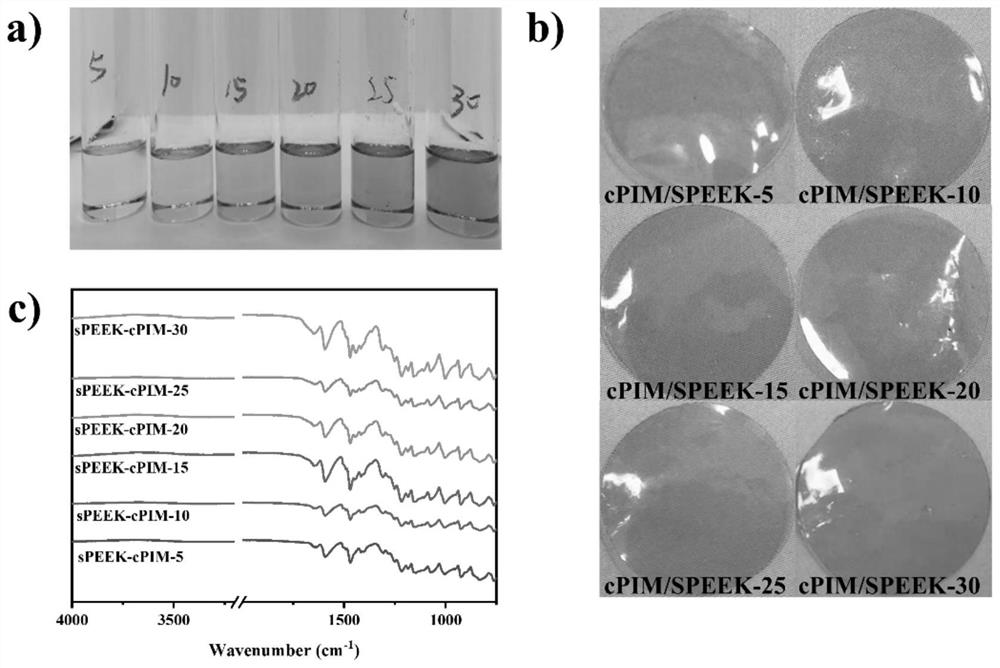

[0031] Example 1 Preparation of PIM-1

[0032] Synthesis of PIM-1: 5.00 g of 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'-spirobiindole (CAS: 77- 08-7, TTSBI) and 3.00g of tetrafluoroterephthalonitrile were added to a 250mL three-necked flask, then 100mL of DMF solution was added, added and mixed well, the mixture was heated at 150°C for 5 hours, and 4.2292g was added during the reaction. Potassium carbonate. After cooling to room temperature, it was poured into water to wash, recrystallized with chloroform / methanol system for more than 3 times to remove impurities, and then vacuum-dried at 120 °C for 24 h to obtain PIM-1 powder, such as figure 1 (a).

Embodiment 2

[0033] Example 2 Preparation of cPIM-1

[0034] Synthesis of cPIM-1: 4.8g of PIM-1 prepared in Example 1 was added to a 250mL three-necked flask, then a mixed solution of 100mL of water and ethanol (mass ratio 1:1) was added, and 40g of sodium hydroxide was added and stirred , the mixture was heated at 120 °C for 7 d. After completion, it was cooled to room temperature, washed with water for several times to remove impurities, and finally activated with 1M hydrochloric acid solution, and then vacuum-dried at 120 °C for 24 h to obtain cPIM-1 powder, such as figure 1 (b) and figure 1 (c).

Embodiment 3

[0035] Example 3 Preparation of sPIM-1

[0036] Synthesis of sPIM-1: 2 g of cPIM-1 prepared in Example 2 was added to 20 mL of concentrated sulfuric acid with a mass-to-volume ratio of 1:10 (the mass of cPIM-1 was 1, and the volume of concentrated sulfuric acid was 10), and after mixing and stirring for 24 h It was poured into purified water and washed to neutrality, and then vacuum-dried at 120 °C for 24 h to obtain sPIM-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com