A kind of surface polishing and grinding equipment for glass processing

A technology for surface polishing and glass parts, applied in metal processing equipment, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of reduced processing efficiency, increased labor costs, unfavorable quality control, etc. Block, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the scope of the patent application of the present invention and the contents of the description still belong to the patent of the present invention covered.

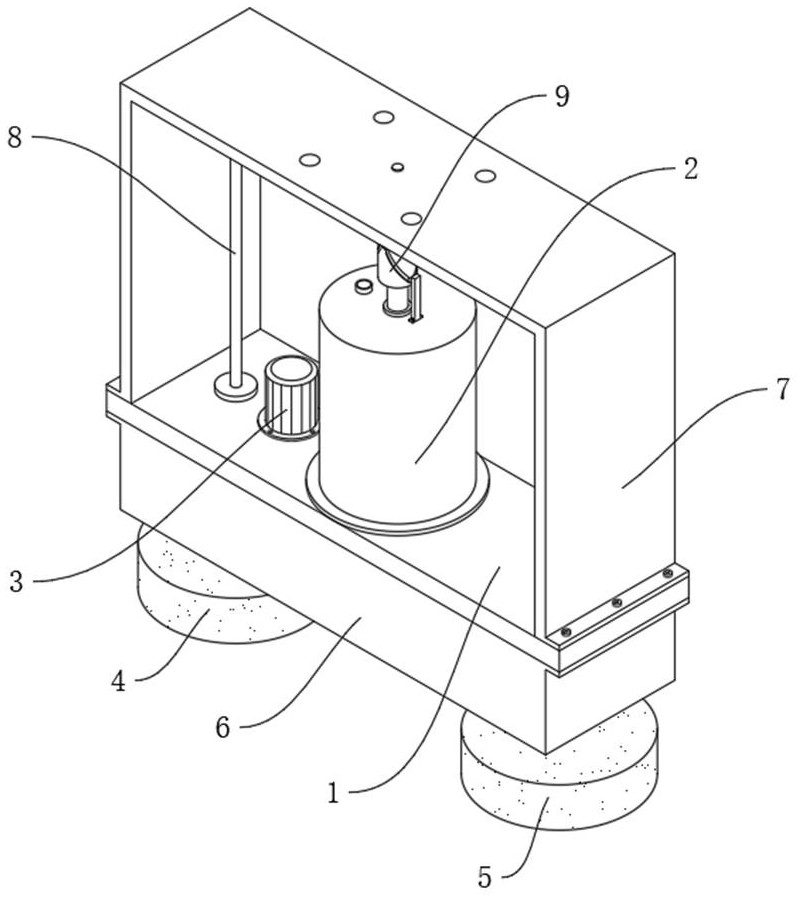

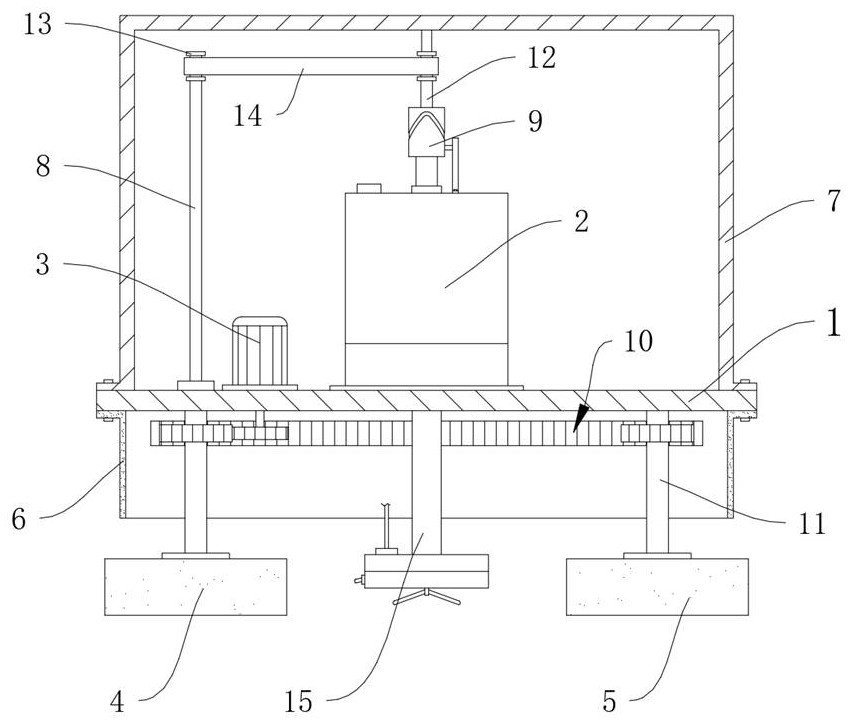

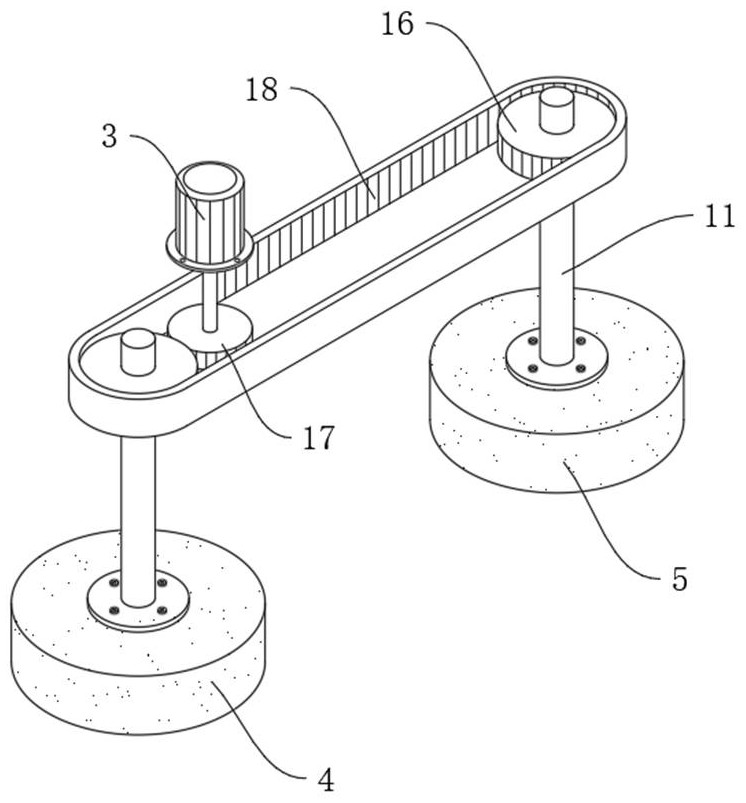

[0040] like figure 1 , figure 2 and image 3Shown: a surface polishing and grinding equipment for glass processing, including a mounting substrate 1, the upper surface of the mounting substrate 1 is provided with a U-shaped mounting frame 7, and the U-shaped mounting frame 7 is used to install on a mechanical drive device, such as a robotic arm, etc. , control the equipment to grind and polish the glass surface. Mounting shafts 11 are rotatably mounted on the lower surface of the mounting base plate 1 near both ends. The bottom ends of the two mounting shafts 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com