Preparation method of lithium bis (fluorosulfonyl) imide and application of lithium bis (fluorosulfonyl) imide

A technology of lithium bisfluorosulfonyl imide and fluorosulfonic acid, which is applied in the application of lithium bisfluorosulfonyl imide and the field of preparation of lithium bisfluorosulfonyl imide, can solve the problem of strong corrosion of hydrofluoric acid and equipment investment Large, unable to obtain LiFSI and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of lithium bisfluorosulfonimide of the present invention includes step (1) fluorination reaction, step (2) catalytic reaction and step (3) lithiation reaction, and the reaction route is as follows.

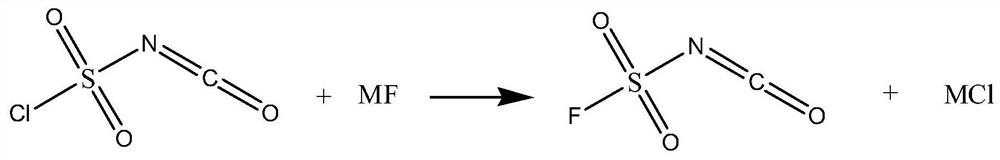

[0030] Preparation of fluorosulfonic acid isocyanate:

[0031]

[0032] Among them: M is a cation such as Na, K, Sb and Zn.

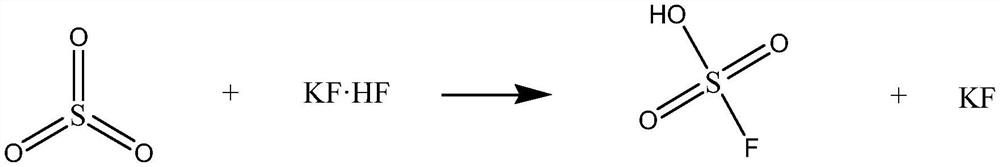

[0033] Preparation of fluorosulfonic acid:

[0034]

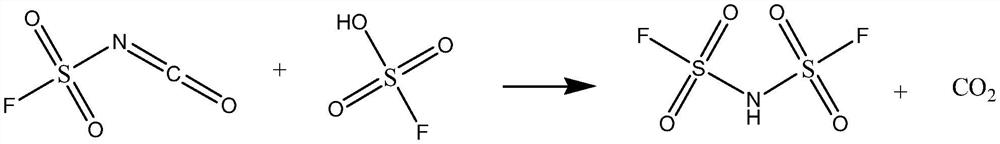

[0035] Preparation of HFSI:

[0036]

[0037] Preparation of LiFSI:

[0038]

[0039] where X is OH - , CO 3 2- isoanion

[0040] Wherein, the fluorination reaction in step (1) includes: a. reacting chlorosulfonic acid isocyanate and fluoride salt and purifying to obtain fluorosulfonic acid isocyanate; b. reacting potassium hydrogen fluoride and fuming sulfuric acid and purifying to obtain fluorosulfonic acid.

[0041] In step a, a fluorinated reagent and chlorosulfonic acid isocyanate can be added to the reaction kettle, the reaction temperature is contro...

Embodiment 1

[0047] The preparation method of lithium bisfluorosulfonimide comprises the steps:

[0048] (1) Fluorination reaction

[0049] Add 142.8g (0.81mol) of antimony trifluoride to a dry 1000ml three-necked flask, heat and stir in an oil bath, set the temperature of the water bath to a constant temperature of 70°C, and slowly dropwise add 339.6g (2.4mol) of isocyanate chlorosulfonate. ), stirred and refluxed for 48h, after the reaction was completed, the temperature was gradually raised to 100°C for atmospheric distillation, and 240 g of a colorless transparent liquid fluorosulfonic acid isocyanate fraction at 80°C was collected, with a purity of 99.9% and a yield of 80%;

[0050] To the dry 1000ml three-necked flask, add 333.3g (2.5mol of sulfur trioxide) (containing 60% sulfur trioxide) oleum, place it in an ice-water bath at 0°C and stir, slowly add 351g of potassium hydrogen fluoride (4.5mol ), stirred and refluxed for 12h, after the reaction was complete, purged with nitrogen,...

Embodiment 2

[0056] The preparation method of lithium bisfluorosulfonimide comprises the steps:

[0057] (1) Fluorination reaction

[0058] In the dry 1000ml there-necked flask, add 125.6g (1.215mol) of zinc fluoride, place it in an oil bath and heat and stir, the water bath temperature is set to 70°C, and slowly dropwise add isocyanate chlorosulfonate 339.6g (2.4mol), The reaction was stirred and refluxed for 48 hours. After the reaction was completed, the temperature was gradually raised to 100 °C for atmospheric distillation, and 234 g of a colorless and transparent liquid fluorosulfonic acid isocyanate fraction at 80 °C was collected, with a purity of 99.9% and a yield of 78%;

[0059] Add 333.3g (2.5mol sulfur trioxide) (containing 60% sulfur trioxide) oleum to a dry 1000ml three-necked flask, place it in an ice-water bath at 0°C and stir, slowly add 351g (4.5mol) of potassium hydrogen fluoride dropwise , stirred and refluxed for 14h, after the reaction was over, purged with nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com