High-performance soft magnetic stainless steel and preparation method thereof

A soft magnetic stainless steel, high-performance technology, applied in the field of stainless steel, can solve the problems of high coercive force of alloy elements, expensive imported products, unfavorable processing and production, etc., and achieve excellent turning performance, excellent soft magnetic properties and optimized production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

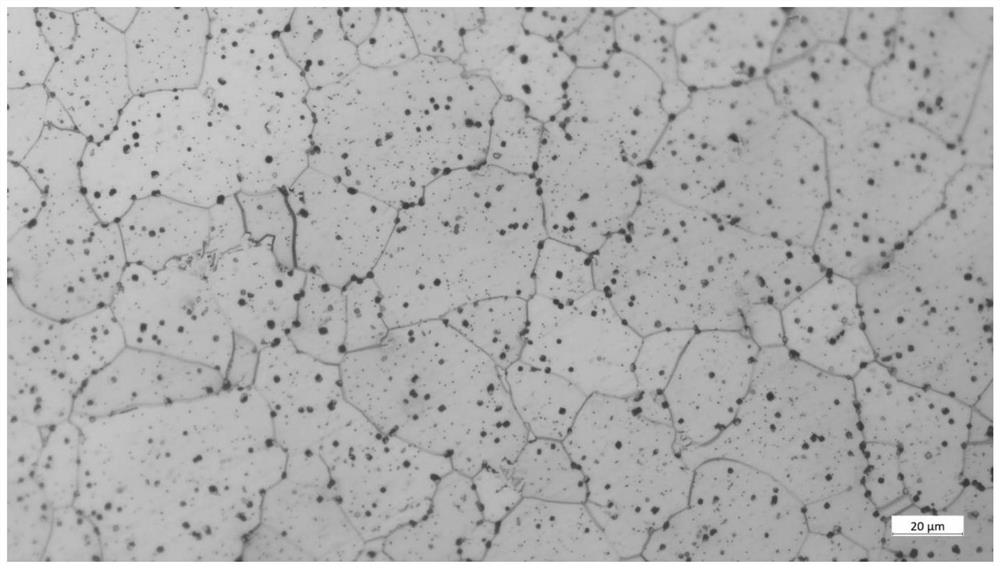

Image

Examples

Embodiment 1

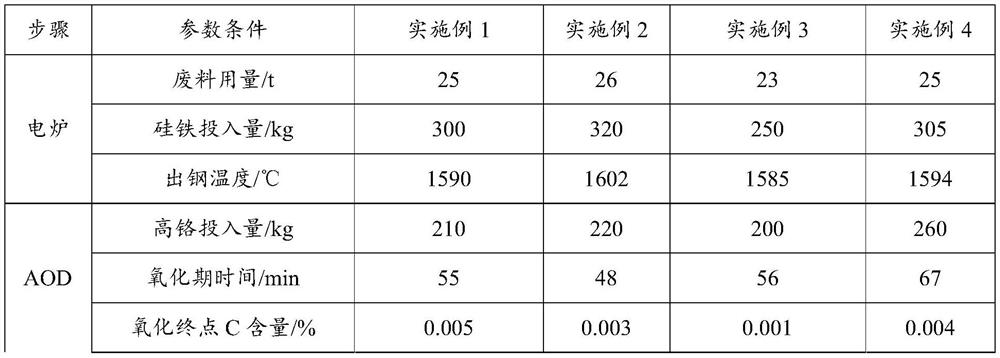

[0060] The chemical composition ratio of a high-performance soft magnetic stainless steel described in this embodiment is shown in Table 1. The above-mentioned high-performance soft magnetic stainless steel production process is: electric furnace smelting → AOD furnace smelting → LF ladle refining → continuous casting → rolling → annealing, specifically:

[0061] Electric furnace smelting: 30 tons of electric furnace is used for smelting, and low-phosphorus stainless steel waste is prepared according to the proportion of components. This time, 25 tons of waste are used. Before adding waste, 1000Kg of lime is added to the bottom of the furnace, and then stainless steel waste is added in 3 times, each time adding 1 300Kg of ferrosilicon is added to reduce it after all melted. Next, adjust the temperature to 1590℃, pull out 2 / 3 of the slag and tap the steel.

[0062] (2) AOD furnace smelting: The smelting process in AOD furnace is mainly divided into oxidation period and reductio...

Embodiment 2

[0069] The chemical composition ratio of a high-performance soft magnetic stainless steel described in this embodiment is shown in Table 1. The difference between the preparation method and Example 1 is that the parameter conditions of each step are shown in Table 2, and a soft magnetic stainless steel is obtained, with a yield of 96.7%.

Embodiment 3

[0071] The chemical composition ratio of a high-performance soft magnetic stainless steel described in this embodiment is shown in Table 1. The difference between the preparation method and Example 1 is that the parameter conditions of each step are shown in Table 2, and a soft magnetic stainless steel is obtained, with a yield of 96.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetic induction | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Residual magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com