Coarse cereal noodles and preparation method thereof

A kind of miscellaneous grain noodles and the technology of the production method are applied in food heat treatment, food science, food drying, etc., which can solve the problems of easy muddy soup and poor palatability of noodles, and achieve the effects of excellent refreshing, excellent lubricity, and good sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In this experiment, millet, barley, mung bean and wheat flour were used as raw materials, in which the proportion of wheat flour was 20%, and the proportion of miscellaneous grain powder was 80%. The proofing time is a single factor, and the cooking loss rate is used as the evaluation index. The production process parameters of the multigrain noodles are optimized through the response surface experiment, in order to produce high-content multigrain noodles with low loss rate and good taste.

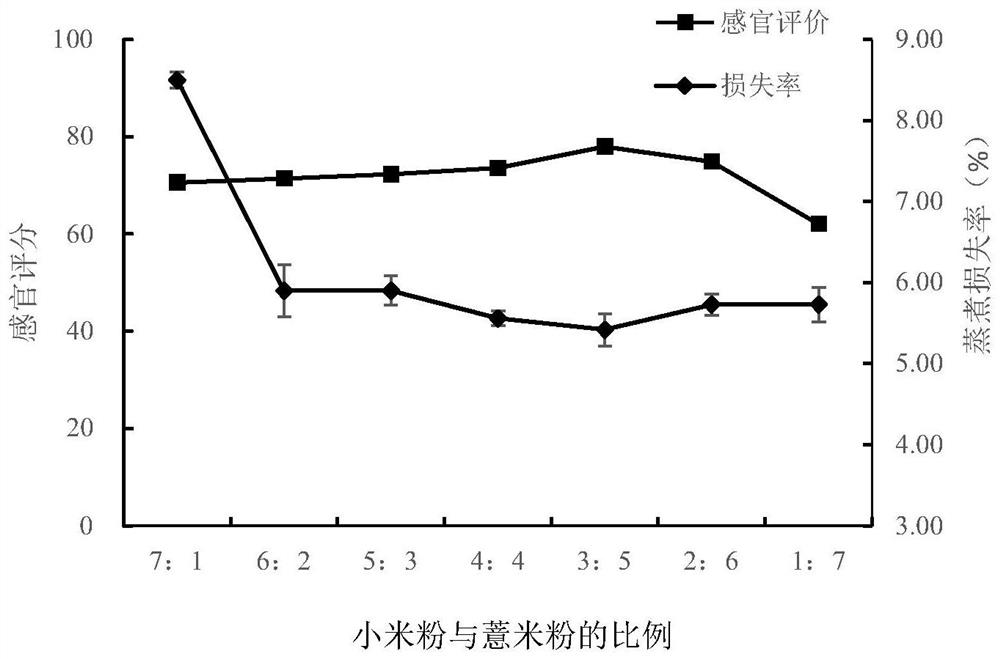

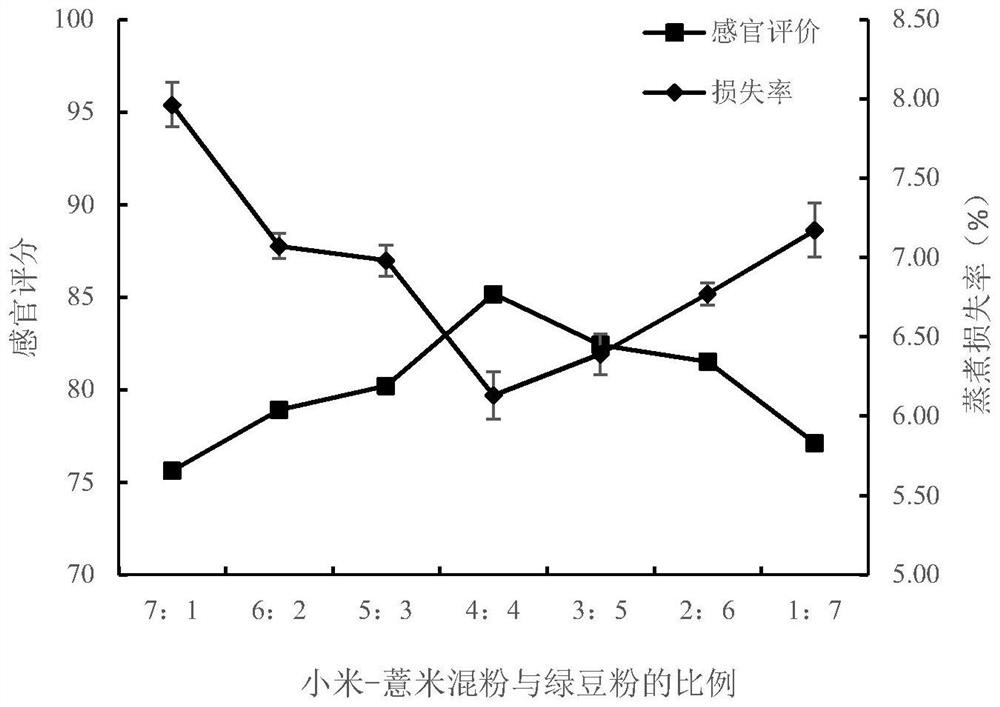

[0060] Compounding of multigrain noodle flour: the total amount of flour is 100%, the proportion of fixed wheat flour is 20%, and the multigrain flour mixed with millet, barley and mung bean is 80%. The technological parameters of kneading were fixed at 50% water addition, 50°C water temperature, and 10min proofing time. Noodles were made by extruding noodle machine, and sensory evaluation value and cooking loss rate were used as evaluation indicators. First, the ratio of millet pow...

Embodiment 2

[0069] Example 2 Optimization of the production process of miscellaneous grain noodles

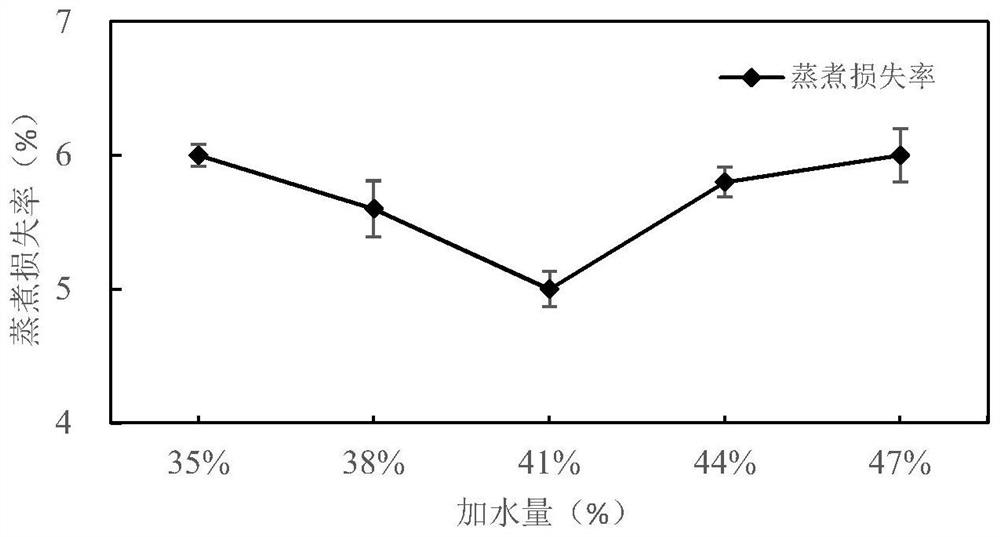

[0070] The effect of water addition on the cooking loss rate of noodles is shown in image 3 , as shown in the figure, when the amount of water added is less than 41%, the cooking loss rate of the noodles gradually decreases, because the amount of water added is getting closer and closer to the water absorption capacity of the mixed powder, so that the gluten protein fully absorbs water and expands to form a gluten network, and the starch also absorbs water. The expansion, encased in the gluten network, increases the elasticity of the noodles, improves the firmness of the noodles, and reduces the cooking time of the noodles, resulting in a lower rate of cooking losses. When the amount of water added exceeds 41%, the amount of water added exceeds the appropriate amount of water, and the viscosity of the dough is dominant in the dough, and the tensile resistance of the noodles is reduced, re...

Embodiment 3

[0079] Embodiment 3 is to the pretreatment test of miscellaneous grain powder

[0080] In this experiment, untreated, ultra-finely pulverized, microwaved, extruded, and spray-dried multigrain powders were used to make noodles at the ratio of wheat: millet: barley: mung bean = 2: 1.5: 2.5: 4. Color difference analysis, in vitro digestion characteristics, noodle texture characteristics, cooking quality, microstructure analysis and sensory evaluation, etc., to explore the adaptability of different pretreatment methods to improve the production of high-content noodle products from multi-grain powder, and the effects of these different treatments on multi-grain products. Influence of noodle quality.

[0081] The specific process of pretreatment is as follows:

[0082] (1) Preparation of multigrain raw powder

[0083] The miscellaneous grain raw materials are pulverized with a pulverizer and passed through an 80-mesh standard sieve to obtain the original powder.

[0084] (2) Prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com