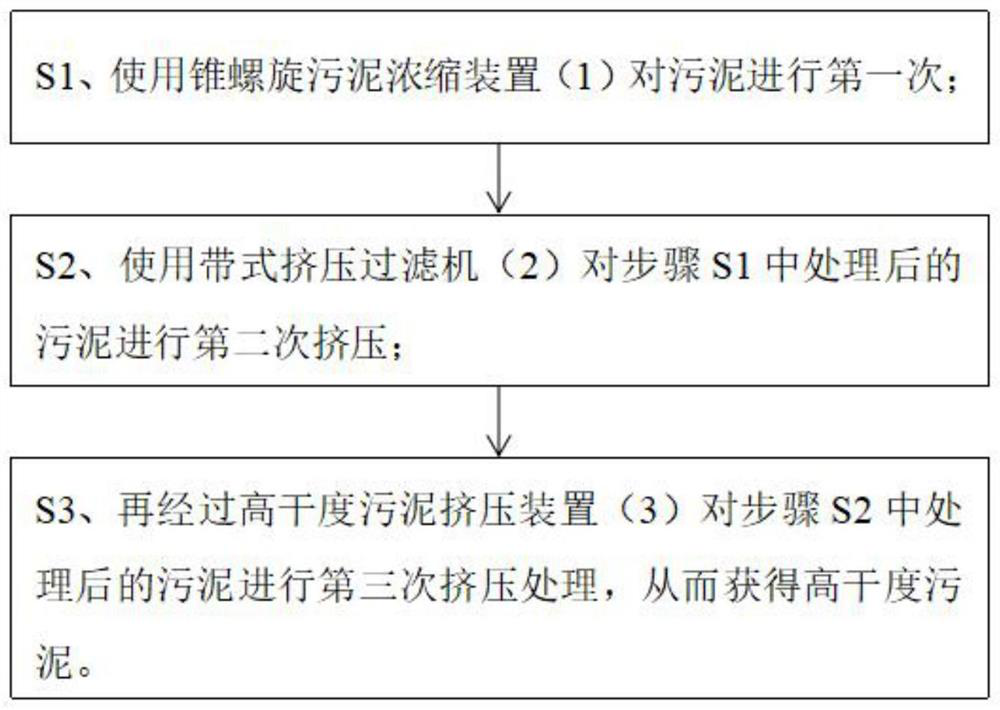

Integrated dehydration process based on high-dryness sludge extrusion device

An extrusion device and high dryness technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of high production cost, high cost, and inability to achieve overall drying , to achieve the effect of improving extrusion efficiency and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This example mainly introduces the devices used in the integrated dehydration process based on the high-dryness sludge extrusion device.

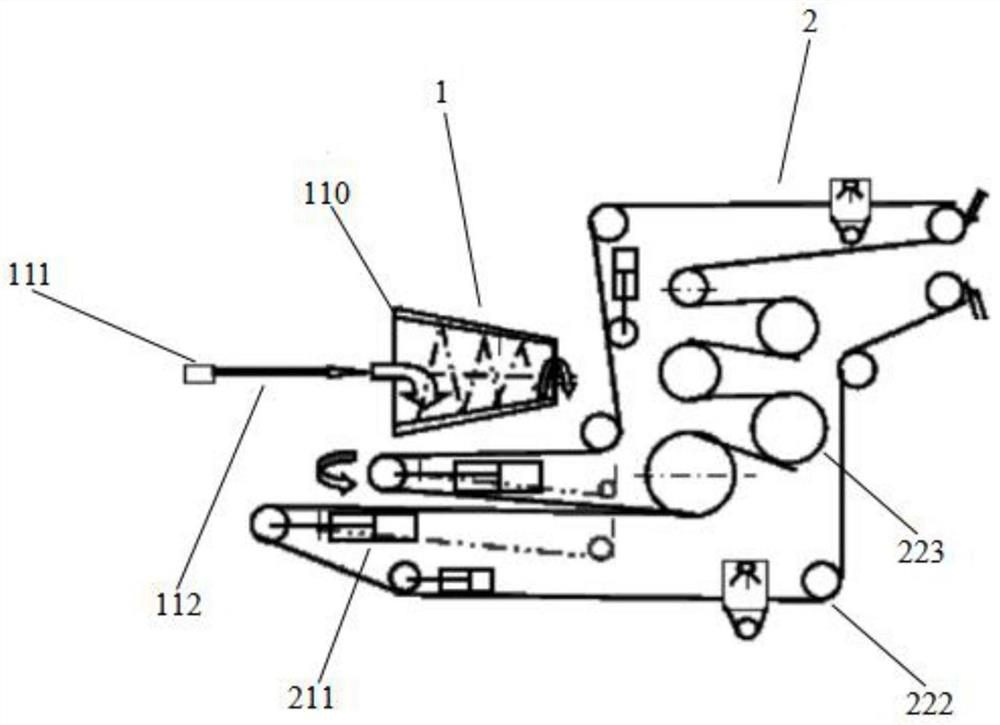

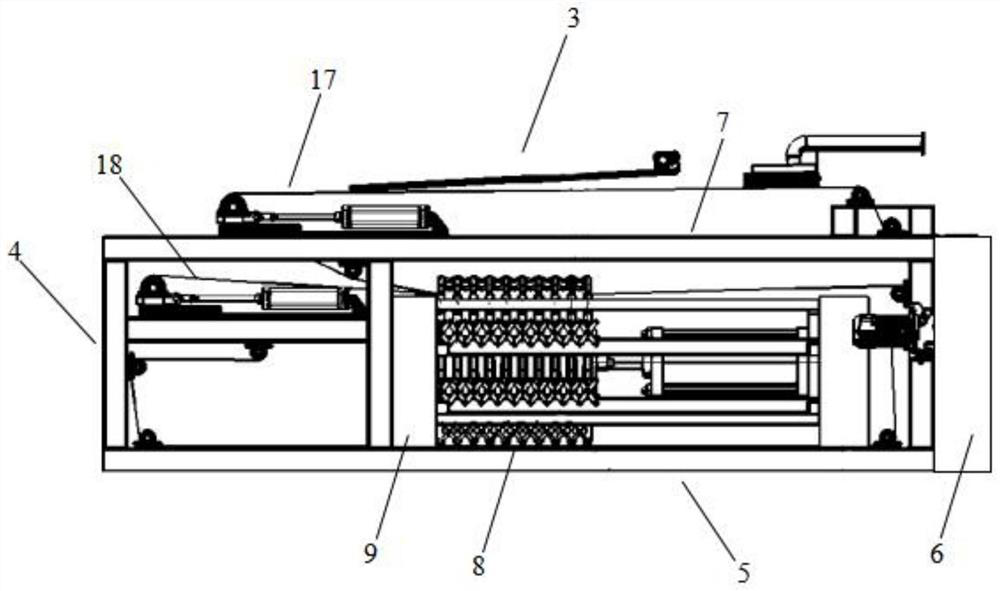

[0061] refer to figure 2 , 3 as shown, figure 2 It is a schematic diagram of the cone-screw sludge thickening device of the present invention, image 3 It is a schematic diagram of the high-dryness sludge extruding device in the present invention. It mainly includes: a cone-screw sludge thickening device 1, a belt extrusion filter 2 and a high-quality sludge extrusion device 3, and the outlet of the cone-screw sludge concentration device 1 is located at the belt extrusion filter 2 The inlet of the belt extrusion filter 2 is located at the inlet of the high-dryness sludge extrusion device 3 .

[0062] Further, the high-dryness sludge extrusion device 3 used in step 3 includes a feed device 4, an extrusion part assembly 5, and a discharge device 6; the feed device 4 is installed on the extrusion part assembly 5 front end, and th...

Embodiment 2

[0085] Based on the foregoing embodiments, this embodiment briefly describes the cone-screw sludge thickening device and the belt squeeze filter in the integrated dehydration process.

[0086] refer to figure 2 as shown, figure 2 It is a schematic diagram of the cone-screw sludge thickening device of the present invention. The cone-screw sludge thickening device 1 used in the step S1 includes a conical shell 110, a fourth rotating motor 111 and a screw 112;

[0087] The round table shell 110 is hollow, and no top cover is provided at both ends. The screw mandrel 112 is located in the round table shell 110. The fourth rotating motor 111 is connected with the screw mandrel 112 through a transmission assembly. The screw mandrel 112 is provided with a continuous The threaded sheet, the pitch of the threaded sheet becomes smaller gradually. As the screw pitch changes from large to small, the extrusion pressure in the cone-screw sludge thickening device 1 increases from small t...

Embodiment 3

[0093] The difference between this embodiment and embodiment 1,2 is:

[0094] Before step S1, a flocculant can also be used to pretreat the sludge for the first time.

[0095] Alternatively, before step S1, a plasma wall-breaking device can also be used to pretreat the sludge, through which the plasma wall-breaking device crushes and shears the sludge, and the plasma generator in the plasma wall-breaking device can also realize Elimination of harmful substances in sludge components and removal of odors in sludge.

[0096] Before step S3, a wide laser intracellular water splitting device can also be used to split the intracellular water of the second squeezed sludge.

[0097] Alternatively, the wide laser intracellular water splitting device can be arranged between the outlet of the belt squeeze filter 2 and the inlet of the belt-type plate and frame ultra-high dryness compressor 3, or between the cone and screw sewage A dehydration treatment is carried out before the mud thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com