High-strength phosphogypsum powder and production method thereof

A production method and technology of gypsum powder, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low conversion rate, affecting the performance and process cost of high-strength gypsum powder, and low strength, so as to improve conversion rate and The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

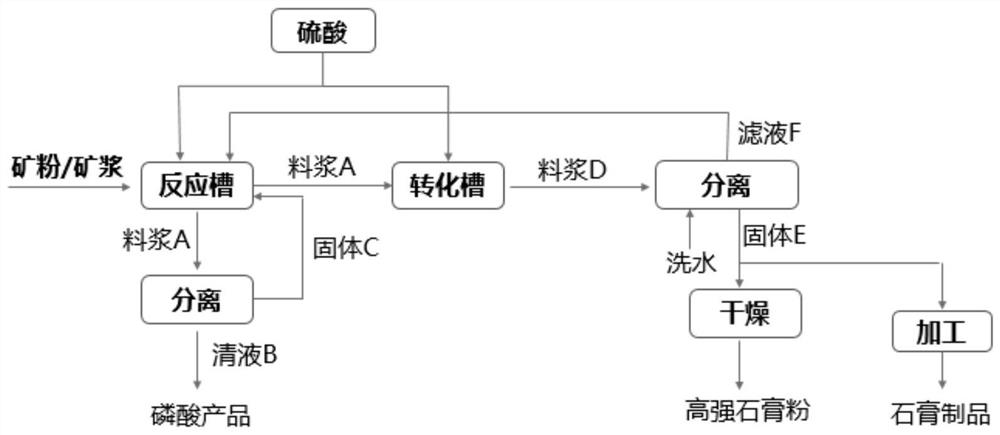

[0032] A method for producing high-strength phosphogypsum powder, comprising the following steps:

[0033] (1) adding phosphate rock slurry and / or phosphate rock powder to the reaction tank, then adding sulfuric acid to react, the temperature of the reaction tank is 90 ° C, and reacted under this condition for 4 hours to obtain mixed slurry A;

[0034] (2) 40% of the volume of the mixed slurry A obtained in the step (1) is separated into solid-liquid separation to obtain clear liquid B and solid C, clear liquid B is sent to acid storage as finished phosphoric acid, and solid C is transferred to the reaction tank , the remaining mixed slurry A is transferred to the conversion tank;

[0035] (3) Add sulfuric acid to the conversion tank, add a surfactant-based crystallizer, and control the liquid-solid ratio and H in the mixed slurry 3 PO 4 and H 2 SO 4 The content of the conversion tank was maintained at 60°C for 2 hours; the organic acid type crystallizer was added, and the...

Embodiment 2

[0049] The difference from Example 1 is that the step (3) is to add sulfuric acid to the conversion tank, add a surfactant class crystallizer cetyl trimethyl ammonium bromide, and control the liquid-solid ratio and H in the mixed slurry. 3 PO 4 and H 2 SO 4 The mixed acid slurry D was obtained by maintaining the temperature of the conversion tank for 6 hours under the condition of 60°C.

Embodiment 3

[0051] Different from Example 1, the step (3) is to add sulfuric acid to the conversion tank, add an organic acid crystal-transforming agent sodium citrate, and control the liquid-solid ratio and H in the mixed slurry. 3 PO 4 and H 2 SO 4 The mixed acid slurry D was obtained by maintaining the temperature of the conversion tank under the condition of 80°C for 6 hours to react.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com