Large-scale egg yolk antibody production method capable of reducing caprylic acid egg residue residues

A technology of egg yolk antibody and caprylic acid, which is applied in the preparation methods of peptides, antibodies, chemical instruments and methods, etc., can solve the problems of strong irritation, animals do not eat, and sudden gastrointestinal diseases, etc. The effect of large dissolved amount, reducing the pressure of resource waste and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

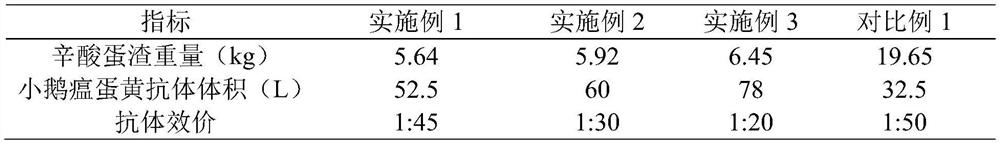

Embodiment 1

[0041] A method that can be used for large-scale production of goose plague yolk antibody, comprising the following steps:

[0042] (1) 1000 gosling plague-free eggs (purchased from Shandong Ennoji Bioengineering Co., Ltd.) were soaked and disinfected with 0.1% Xinjieermin for 15 minutes;

[0043] (2) mechanically beating the cleaned and sterilized high-free eggs to obtain egg yolks;

[0044] (3) inject the egg yolk obtained in the step (2) into the egg stirring tank, the egg yolk is stirred and mixed, and the stirring speed is 200rpm to obtain egg yolk liquid;

[0045] (4) Under the condition of 25°C, prepare the glacial acetic acid-sodium acetate buffer solution of 4.4 times the volume of egg yolk liquid in the acidification tank, and adjust the pH to 5.4 with sodium hydroxide;

[0046] (5) the prepared acidified water is injected into the egg yolk liquid prepared in step (3), stirring time is 30min, stirring speed is 130rpm, after stirring, leave standstill at room tempera...

Embodiment 2

[0052] A method that can be used for large-scale production of goose plague yolk antibody, comprising the following steps:

[0053] (1) 1000 gosling plague-free eggs (purchased from Shandong Ennoji Bioengineering Co., Ltd.) were soaked and disinfected with 0.1% Xinjieermin for 15 minutes;

[0054] (2) mechanically beating the cleaned and sterilized high-free eggs to obtain egg yolks;

[0055] (3) inject the egg yolk obtained in the step (2) into the egg stirring tank, the egg yolk is stirred and mixed, and the stirring speed is 200rpm to obtain egg yolk liquid;

[0056] (4) Under the condition of 25°C, prepare 5.2 times the volume of glacial acetic acid-sodium acetate buffer solution of egg yolk in an acidifying tank, and adjust the pH to 5.0 with sodium hydroxide;

[0057] (5) the prepared acidified water is injected into the egg yolk liquid prepared in step (3), stirring time is 30min, stirring speed is 160rpm, after stirring, leave standstill at room temperature for overni...

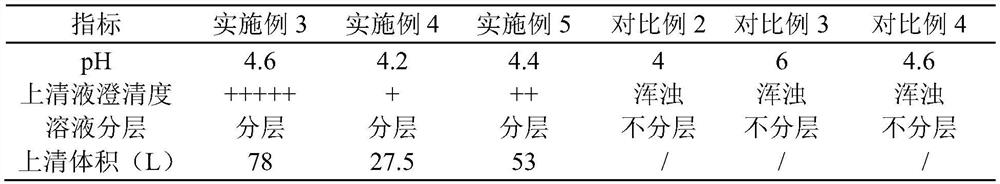

Embodiment 3

[0063] A method that can be used for large-scale production of goose plague yolk antibody, comprising the following steps:

[0064] (1) 1000 gosling plague-free eggs (purchased from Shandong Ennoji Bioengineering Co., Ltd.) were soaked and disinfected with 0.1% Xinjieermin for 15 minutes;

[0065] (2) mechanically beating the cleaned and sterilized high-free eggs to obtain egg yolks;

[0066] (3) inject the egg yolk obtained in the step (2) into the egg stirring tank, the egg yolk is stirred and mixed, and the stirring speed is 300rpm to obtain egg yolk liquid;

[0067] (4) Under the condition of 25°C, prepare 5.8 times the volume of glacial acetic acid-sodium acetate buffer solution of egg yolk in an acidifying tank, and adjust the pH to 4.6 with sodium hydroxide;

[0068] (5) the prepared acidified water is injected into the egg yolk liquid prepared in step (3), stirring time is 25min, stirring speed is 100rpm, after stirring, leave standstill at room temperature for overni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com