Aluminum material anti-oxidation composition as well as preparation method and application thereof

An anti-oxidation and composition technology, applied in the field of aluminum anti-oxidation composition and its preparation, can solve the problems of cleaning to remove, can not increase the lubricating performance of aluminum materials, etc. layer, economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides an anti-oxidation composition for aluminum materials, which, in terms of mass percentage concentration, comprises: aluminum corrosion inhibitor DX5830 40%, trihydroxypropane oleate 6%, Tween-80 14%, calcium stearate 4%, cleaning agent 10%, organic mildew inhibitor 1%, organosiloxane defoamer 3% and the balance deionized water.

[0036] Take 1 part by mass of the antioxidant composition and dilute it with 15 parts by mass of deionized water to prepare a lubricating cooling process liquid, which is placed in a chute (length 300m), and the temperature is controlled at 40-55°C. In the process, the aluminum material passes through the chute at 70-90m / min, and the aluminum material is immersed in the lubricating and cooling process liquid for 0.2-0.3s. A 1mm thick elastic rubber is used to scrape it first and then dry it with hot air. An anti-oxidation film with a thickness of 5-10 microns is formed on the surface.

[0037] The effect of this antioxi...

Embodiment 2-6

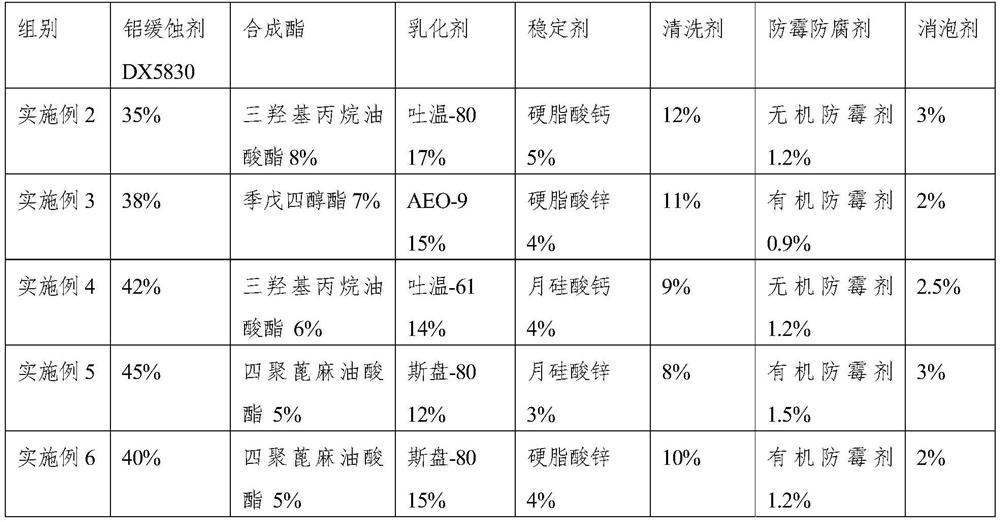

[0042] Embodiments 2-6 respectively provide an aluminum anti-oxidation composition, the ingredients of which are as follows (the part that is less than 100% is filled with water):

[0043]

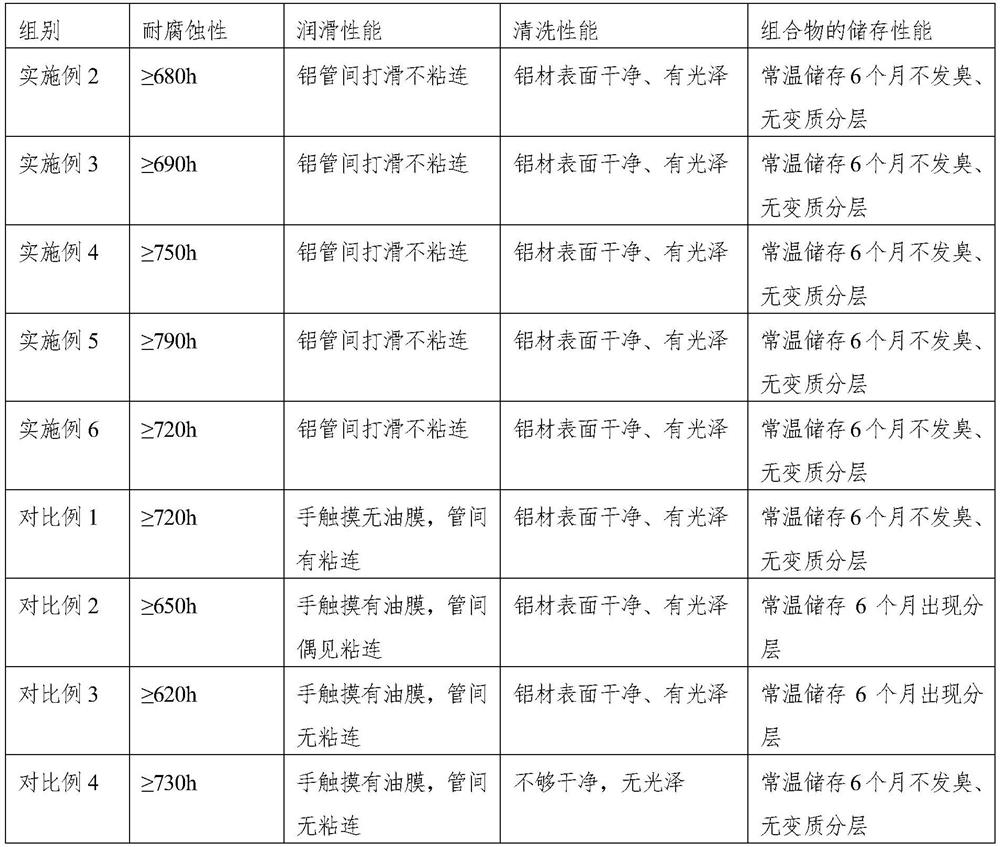

[0044] In order to further illustrate the technical effect of the present invention, the following comparative example is also set.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com